Fiberglass Facing Black Fiberglass Tissue for Glasswool-65EP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction of Fiberglass Tissue

Fiberglass Tissue is a kind of facing, which is made of by the white fiberglass tissue, and special production process.

Application of Fiberglass Tissue

Our black tissue are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also fiberglass tissue facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Fiberglass Tissue

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Fiberglass Tissue

1. Waterproof paper then PVC shrinking Film

2. Water-Proof film only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

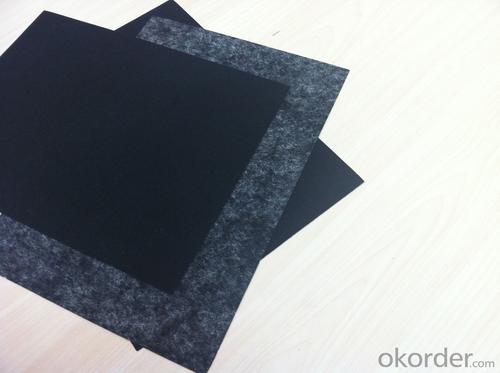

Pictures of Fiberglass Tissue

Specification of Fiberglass Tissue

Specification | ||

ITEM | UNIT | VALUE |

Type | C | |

Weight | g/m2 | 65±5 |

Thickness | mm | 0.40 |

Tensile Strength MD | n/125px | ≥130 |

Tensile Strength XD | n/125px | ≥90 |

Fiber Diameter | µ | 9 |

Fire Resistant Property | B1 | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to utilize black fiberglass tissue as a material that is resistant to fire?

- <p>Yes, black fiberglass tissue can be used as a fire-resistant material. Fiberglass, which is made of glass fibers, is naturally resistant to fire due to its non-flammable nature. It does not burn and can withstand high temperatures without melting, making it an effective insulator against heat. The black color does not affect its fire-resistant properties, and it is often used in construction and industrial applications where fire safety is a concern.</p>

- Q: How is fiberglass facing used in construction?

- Construction commonly utilizes fiberglass facing as a safeguard for insulation materials, effectively applying it to the outer side of insulation boards or blankets. This facing is crafted from woven fiberglass fabric or reinforced foil, bolstering the insulation's sturdiness and resilience. A primary function of fiberglass facing in construction is to serve as a vapor barrier, effectively thwarting moisture from permeating the insulation and reducing the likelihood of condensation and mold growth. By maintaining the insulation's dryness, its thermal capacity endures and its lifespan is prolonged. Furthermore, fiberglass facing also functions as a radiant barrier, reflecting radiant heat and thereby minimizing heat transfer between the surroundings and the insulation. This attribute proves especially advantageous in warm climates or when insulating buildings that receive direct sunlight exposure. Moreover, fiberglass facing enhances the mechanical properties of insulation materials, providing structural reinforcement and guarding against harm during handling, transportation, and installation. It also heightens the insulation system's fire resistance by acting as a shield against flames and curtailing the spread of fire. To summarize, fiberglass facing is an adaptable component employed in construction to augment the performance and longevity of insulation materials. It acts as a vapor barrier, radiant barrier, and protective layer, ensuring that buildings possess effective insulation, energy efficiency, and safety.

- Q: What are the benefits of using fiberglass facing?

- There are several benefits of using fiberglass facing in various applications. Firstly, fiberglass facing offers excellent strength and durability, making it highly resistant to cracking, warping, and other forms of damage. This makes it ideal for use in construction and structural applications where strength and longevity are important factors. Additionally, fiberglass facing provides excellent thermal insulation properties. It has a low thermal conductivity, meaning it can effectively prevent heat transfer and maintain a consistent temperature in both hot and cold environments. This makes it a popular choice for insulation in buildings, HVAC systems, and other applications where energy efficiency is a key consideration. Another advantage of fiberglass facing is its resistance to moisture and corrosion. It is non-porous and does not absorb water, making it highly resistant to mold, mildew, and rot. This makes it a suitable material for use in damp or humid environments, such as bathrooms and kitchens. Furthermore, fiberglass facing is lightweight and easy to handle, making it convenient to install and transport. It can be easily cut and shaped to fit various surfaces and configurations, allowing for flexibility in design and installation. Its lightweight nature also reduces the strain on supporting structures, making it a cost-effective choice for construction projects. Lastly, fiberglass facing is available in a wide range of sizes, thicknesses, and finishes, allowing for customization to meet specific project requirements. It can be coated or laminated with different materials to enhance its performance, such as adding a vapor barrier or reflective surface. This versatility makes it suitable for a variety of applications in industries ranging from construction to transportation. In summary, the benefits of using fiberglass facing include its strength and durability, thermal insulation properties, resistance to moisture and corrosion, lightweight nature, and customization options. These advantages make it a popular choice in various industries where these characteristics are valued.

- Q: This question asks for a comparison of the cost of black fiberglass tissue with other fiberglass products.

- <p>The price of black fiberglass tissue can vary significantly compared to other types of fiberglass products due to factors such as quality, thickness, and market demand. Generally, it may be more expensive than standard white fiberglass due to its additional benefits like UV resistance and aesthetic appeal. However, prices can fluctuate based on the manufacturer, the specific product's properties, and the current market conditions. It's best to check with suppliers for the most accurate and up-to-date pricing information.</p>

- Q: What is the specific weight of black fiberglass tissue, and how is it measured?

- <p>The density of black fiberglass tissue, also known as black glass fiber fabric, is typically measured in grams per cubic centimeter (g/cm鲁). It can vary depending on the specific type and weave of the fiberglass, but generally, it ranges from 0.2 to 0.4 g/cm鲁. This density is determined by the weight of the fibers per unit volume. To measure the density, one would weigh a known volume of the fiberglass tissue and divide the mass by the volume to get the density in g/cm鲁.</p>

- Q: Is it possible to utilize black fiberglass tissue in construction?

- <p>Yes, black fiberglass tissue can be used as a building material. It is known for its strength, durability, and resistance to various environmental factors, making it suitable for construction purposes. It is often used in the form of reinforced plastic or composite materials, enhancing the structural integrity of buildings and providing insulation. However, it's important to follow specific guidelines and regulations for its use in construction to ensure safety and effectiveness.</p>

- Q: This question asks about the impact of black fiberglass tissue on the quality of air inside residential homes.

- <p>The use of black fiberglass tissue in residential homes can affect indoor air quality in various ways. Black fiberglass is a type of insulation material that can help retain heat and reduce energy costs. However, if it contains certain chemicals or if it's improperly installed, it may release fibers or particles into the air, potentially causing respiratory issues or allergies. Additionally, if the fiberglass is not treated to resist moisture, it could lead to mold growth, further impacting air quality. It's important to ensure that any fiberglass insulation used in homes is of high quality, properly installed, and treated to prevent such issues. Regular maintenance and air quality checks can also help maintain a healthy indoor environment.</p>

- Q: Is it safe to place black fiberglass tissues in a dishwasher without causing damage or releasing harmful substances?

- <p>It is generally not recommended to use black fiberglass tissues in a dishwasher. Fiberglass is a type of plastic that can be damaged by the high heat and water pressure in a dishwasher. Additionally, the black color may be due to dye, which could potentially leach out and stain other dishes. To maintain the integrity of your fiberglass items and the cleanliness of your dishwasher, it's best to wash them by hand using warm, soapy water.</p>

- Q: This question asks whether black fiberglass tissue can be recycled multiple times.

- <p>Black fiberglass tissue can be recycled, but its recyclability diminishes with each cycle due to the degradation of its physical properties. The first recycling process is usually the most effective, and subsequent recyclings result in a material of lower quality. Fiberglass, being a composite material, faces challenges in the recycling process because it combines glass fibers with plastic resins. While some industries may reuse fiberglass for specific purposes, it's not typically recycled multiple times like some other materials due to the loss in strength and structural integrity.</p>

- Q: What distinguishes different grades of black fiberglass tissues in terms of their properties and applications?

- <p>The differences between various grades of black fiberglass tissues primarily lie in their fiber diameter, weight per unit area, tensile strength, and chemical resistance. Lower grades typically have coarser fibers and lower tensile strength, suitable for general applications like insulation. Higher grades feature finer fibers, higher tensile strength, and better chemical resistance, making them ideal for more demanding applications such as high-temperature environments or chemically aggressive settings. Each grade's specific properties determine its suitability for particular industrial uses.</p>

Send your message to us

Fiberglass Facing Black Fiberglass Tissue for Glasswool-65EP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords