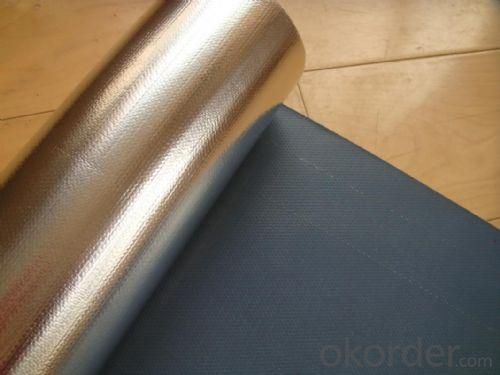

Fiberglass Fabrics Reinforced with High Quality Aluminium Foil

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of High Quality Fiberglass Fabrics Aluminium Foil:

The High Quality Fiberglass Fabrics Aluminium Foil is an engineering material weaved with glass fiber, which has the excellent merit such as anti-burns, anti-corrosion, stable-size, heat isolation, minimum elongated shrinkage, high intensity.It is widely used to make PVC fabric, water-proof material, free-proofing canvas and heat preservation materials.

Technical Data Sheet of High Quality Fiberglass Fabrics Aluminium Foil:

Fabric Count Warp×Fill(Per cm) | Yarn(SI)

| Thickness(mm) (Rreference Only) | Nominal Weight(g/m2) | Weight Tolerance(g/m2) |

23.6×18.5 | 5 11 1×0 5 11 1×0 | 0.053 | 46.8 | 45.1-48.5 |

23.6×23.6 | 5 11 1×0 5 11 1×0 | 0.056 | 52.9 | 51.5-54.2 |

19.3×16.5 | 7 45* 1×0 7 45* 1×0 | 0.149 | 164.1 | 157.7-170.5 |

18.1×17.7 | 7 45* 1×0 7 45* 1×0 | 0.140 | 1654.0 | 158.0-171.0 |

23.6×19.7 | 6 33 1×0 6 33 1×0 | 0.125 | 148.0 | 142.8-153.2 |

20.0×10.8 | 9 331×0 9 74 1×0 | 0.135 | 146.2 | 142.1-150.3 |

20.5×20.5 | 9 34* 1×0 9 34* 1×0 | 0.114 | 138.3 | 133.6-143. |

23.6×22.0 | 7 22 1×0 5 11 1×0 | 0.079 | 78.0 | 75.6-80.4 |

22.0×18.9 | 7 22 1×0 7 22 1×0 | 0.084 | 90.9 | 88.5-93.2 |

23.6×22.8 | 7 22 1×0 7 22 1×0 | 0.094 | 103.8 | 100.7-106.8 |

26.0×21.7 | 7 22 1×0 7 22 1×0 | 0.095 | 108 | 104.8-111.2 |

17.3×12.2 | 9 681×0 9 68 1×0 | 0.173 | 203.4 | 198.0-208.9 |

17.9×13.4 | 9 68 1×0 9 68 1×0 | 0.18 | 210.0 | 204.5-215.3 |

17.3×11.4 | 9 68 1×0 9 102* 1×0 | 0.201 | 232.3 | 226.5-238.0 |

17.5×7.9 | 9 68 1×0 9 136* 1×0 | 0.254 | 227.8 | 221.1-234.7 |

17.4×10 | 9 68 1×0 9 136* 1×0 | 0.250 | 260.0 | 255.2-265.3 |

- Q: What does "PCB" mean?

- What is the raw material of PCB (printed circuit board)? We know there is something called "glass", this kind of material in our daily life. Obviously, such as core fireproof cloth, fireproof felt is glass fiber, glass fiber and resin is easy to combine, we put into the tree structure of glass fiber cloth and high strength grease, hardening has heat insulation PCB, not easy to bend the substrate -- if the PCB board is broken, white edge delamination, enough to prove that the material is glass fiber resin.

- Q: What kind of fiberglass cloth should be used for keeping the chicken boarding board?

- The rigid polyurethane has low thermal conductivity and high compressive strength. The relatively thin plate can meet the thermal functional requirements of buildings, and the building load can be built.

- Q: Can fiberglass fabric be used for making car seat covers?

- Indeed, car seat covers can be crafted using fiberglass fabric. Renowned for its durability, strength, and heat resistance, fiberglass fabric emerges as an ideal material for this purpose. Its lightweight nature and effortless manipulation further enhance its popularity in automotive applications. Moreover, fiberglass fabric showcases stain resistance and effortless cleaning, making it indispensable for car seat covers that frequently encounter spills and dirt. Nevertheless, it is crucial to acknowledge that fiberglass fabric may be less comfortable than alternative materials, necessitating additional padding or cushioning to ensure a pleasant seating experience.

- Q: Can fiberglass fabric be used for making heat shields?

- Indeed, heat shields can be made using fiberglass fabric. Renowned for its exceptional heat resistance properties, fiberglass fabric proves to be an optimal material for heat shielding purposes. Withstanding elevated temperatures without succumbing to melting or deformation, it effectively acts as a protective barrier against heat transfer. Furthermore, fiberglass fabric possesses the advantageous traits of being lightweight, flexible, and possessing commendable insulation properties, rendering it appropriate for a diverse range of heat shield applications across the automotive, aerospace, and industrial sectors.

- Q: Can fiberglass fabric be used for reinforcement in automotive parts?

- Indeed, automotive parts can be reinforced with fiberglass fabric. Renowned for its exceptional strength-to-weight ratio, fiberglass fabric proves to be an optimal material for reinforcing diverse components within automobiles. Its utilization is prevalent in the production of body panels, hoods, fenders, and other integral structural parts of vehicles. By endowing remarkable rigidity and stiffness, fiberglass fabric significantly enhances the overall strength and longevity of automotive parts. Furthermore, its resistance to corrosion, coupled with its ability to endure high temperatures, renders fiberglass fabric highly suitable for deployment within the automotive industry.

- Q: Can fiberglass fabric be used for insulation in storage tanks?

- Fiberglass fabric is indeed suitable for insulation in storage tanks. Its remarkable thermal properties make it an optimal selection for insulation purposes. With its low thermal conductivity, it effectively diminishes heat transfer and maintains the desired temperature of the storage tank contents. Moreover, fiberglass fabric offers the advantages of being lightweight, flexible, and easy to install, rendering it a convenient alternative for insulating storage tanks of diverse sizes and shapes. Additionally, it possesses resistance against moisture, chemicals, and UV radiation, guaranteeing its durability and long lifespan. All in all, fiberglass fabric stands as a trustworthy and effective option for insulating storage tanks.

- Q: Can fiberglass fabrics be used for insulation in aerospace components?

- Indeed, insulation in aerospace components can utilize fiberglass fabrics. Renowned for its exceptional thermal insulation properties, fiberglass finds extensive employment across diverse industries, including aerospace. Its lightweight nature, flexibility, and ability to endure high temperatures render it an ideal choice for insulating various aerospace components like engine compartments, fuel tanks, and exhaust systems. Furthermore, the resistance of fiberglass fabrics to chemicals, moisture, and fire further bolsters their aptness for insulation applications within the aerospace realm.

- Q: How is fiberglass fabric used in the production of wind turbine blades?

- Fiberglass fabric is extensively used in the production of wind turbine blades due to its exceptional properties and advantages. The fabric is typically made from woven fiberglass filaments, which are lightweight, strong, and highly durable. One of the most significant uses of fiberglass fabric in wind turbine blades is as the main structural material. The fabric is typically layered and impregnated with a resin, such as epoxy, to form a composite material known as fiberglass-reinforced polymer (FRP). This FRP composite provides the required strength and stiffness to withstand the forces and stresses experienced by the blades while operating in the wind. The process of incorporating fiberglass fabric into wind turbine blades involves several steps. First, a mold is created in the shape of the blade using a positive model. Layers of fiberglass fabric are then carefully placed onto the mold, with each layer oriented in a specific direction to optimize the blade's mechanical properties. The fabric layers are impregnated with resin, ensuring that the entire structure is bonded together. This process is often repeated multiple times to increase the thickness and strength of the blade. The advantages of using fiberglass fabric in wind turbine blades are numerous. Firstly, the fabric's lightweight nature allows for the construction of longer and larger blades, enabling more efficient energy capture from the wind. Additionally, fiberglass fabric is highly resistant to corrosion, making it an ideal choice for outdoor applications, where the blades are constantly exposed to harsh environmental conditions. Furthermore, the inherent flexibility of fiberglass fabric allows the blades to bend and twist with the changing wind conditions, effectively reducing unnecessary stress and enhancing overall performance. The fabric is also resistant to fatigue, meaning that it can withstand repeated loading cycles without compromising its structural integrity. Overall, fiberglass fabric plays a crucial role in the production of wind turbine blades by providing the necessary strength, durability, and flexibility required for efficient and reliable energy generation. Its lightweight nature, corrosion resistance, and fatigue resistance make it an ideal material choice for constructing blades that can withstand the demanding operating conditions of wind turbines.

- Q: Is fiberglass fabric resistant to insects?

- Yes, fiberglass fabric is generally resistant to insects.

- Q: How to deal with thermal cracking of exterior wall?

- Replacement of existing insulation materials and repair of cracks. After cracking, often cause leakage passage. The water insulation layer, thermal insulation performance, such as freeze-thaw damage. At this time, the impact of the scope of the heat preservation material replacement, re construction. Then, if the insulation layer and wall have been cracking, we should use glue, grouting (epoxy resin) and other practices to plug the gap. Insulation materials are loose, and reinforcement measures such as studs. Replacement of insulation materials and large surface materials are often not bonded, encryption reinforcement measures should be taken.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Fabrics Reinforced with High Quality Aluminium Foil

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords