Fiberglass Fabrics - e-glass stitich combo mat- tlx top quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

E-glass stitched combo mat consists of two or more layers of fiberglass roving which are stitch-bonded.One layer of rovings and different layers of roving can be oriented differently and have different liner density.The roving specification,number of roving layers,mat width and roll diameter can be customized as per requirement.

Application:

The product is most widely used in hand lay-up process and also can be used in filament winding. compression molding and continuous laminating processes. The typical end products including various panels, boats,bath equipment automotive parts and cooling towers

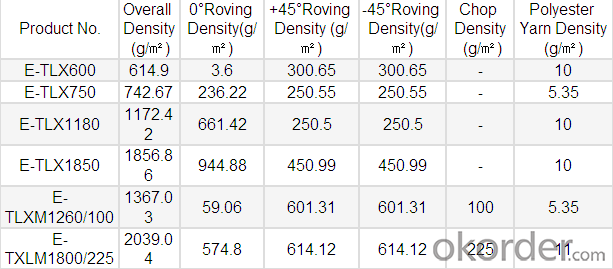

Specifications:

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Construction method of organosilicon waterproof coating

- Coating: construction can be used to roll, scrape, paint and brush can be, generally painted 3-4 scraping, each scraping scraping reference amount of 0.8-1.0 kg / square meter.

- Q: What is the typical tear strength of fiberglass fabrics?

- The typical tear strength of fiberglass fabrics can vary depending on the specific type and construction of the fabric. However, in general, fiberglass fabrics are known for their high tear strength. They are designed to be durable and resistant to tearing, making them suitable for a wide range of applications. On average, fiberglass fabrics can have tear strengths ranging from 10 to 30 pounds-force per inch (lbf/in), with some specialized fabrics reaching even higher tear strengths. It is important to note that tear strength can also be influenced by factors such as fabric thickness, weave pattern, and resin impregnation. Therefore, it is recommended to consult the specific manufacturer's specifications for accurate tear strength values for a particular fiberglass fabric.

- Q: Can fiberglass fabric be used for making backpacks or luggage?

- Yes, fiberglass fabric can be used for making backpacks or luggage. Fiberglass fabric is known for its strength and durability, making it an excellent choice for creating sturdy and long-lasting bags. It is lightweight, resistant to tear and abrasion, and can withstand heavy loads. Additionally, fiberglass fabric is often used in industries where strength and durability are essential, such as aerospace and automotive, further highlighting its suitability for backpacks and luggage. However, it is worth noting that fiberglass fabric may not be as flexible or moldable as other materials, so it may be more suitable for rigid or structured bag designs rather than soft or collapsible styles.

- Q: Magnesite material instability made sheds or greenhouse skeleton for a few years

- At present, many manufacturers of magnesite skeleton do not understand what technology utterly ignorant of, and dynamic requirements of raw materials ratio, magnesite modified and other technical problems, the paper presented the formula "only does not have the feasibility! The vast number of friends after the birth of the production of a large number of "problem products", not "brine", that is, water poor performance! In this remind the vast number of ready to receive production of friends should pay special attention to avoid being deceived!

- Q: How is fiberglass fabric used in the production of boat hulls?

- Due to its exceptional strength, durability, and lightweight nature, fiberglass fabric finds extensive use in the production of boat hulls. This versatile material is created by weaving together fine strands of glass into a fabric, which is then impregnated with a resin, typically polyester or epoxy, to form a solid and rigid composite structure. When it comes to boat hull production, fiberglass fabric serves as a reinforcement material. It is commonly applied in multiple layers, known as laminate, to construct a robust and inflexible hull. The fabric is initially laid down on a mold or frame, taking the desired shape of the boat. Then, the resin is applied over the fabric, fully saturating it and creating a bond between the layers. Once the resin cures and hardens, the fiberglass fabric becomes an integral component of the boat hull. It provides structural integrity, rendering the hull resistant to impacts, flexing, and water damage. The strength of the fiberglass fabric ensures that the hull can withstand the stresses and forces encountered during boating, such as waves, wind, and collisions. Additionally, fiberglass fabric exhibits excellent resistance to corrosion, rot, and degradation caused by exposure to water, making it an ideal choice for boat hulls. It is also relatively easy to shape and mold, enabling boat manufacturers to create hulls of various designs and sizes. Furthermore, if the hull sustains any cracks or punctures, fiberglass fabric can be easily repaired. Simply applying a new layer of fiberglass fabric and resin over the damaged area ensures that the boat remains structurally sound and watertight. In conclusion, fiberglass fabric plays a crucial role in boat hull production by providing strength, durability, and resistance to water damage. Its versatility and ease of repair make it a preferred choice for boat manufacturers worldwide.

- Q: How much resin does 1 square meter 02 fiberglass cloth need to consume?

- Resin: glass fiber 6:4 technique can be better 5:5; high alkali cloth the most expensive resin; followed by medium alkali cloth; most of the resin is alkali free cloth.

- Q: What are the advantages of using fiberglass fabrics?

- Using fiberglass fabrics in various industries offers several advantages. Firstly, fiberglass fabrics are renowned for their exceptional strength-to-weight ratio. This implies that they possess remarkable strength and durability while maintaining a lightweight composition. Consequently, fiberglass fabrics prove to be ideal for industries that prioritize both strength and weight, such as aerospace and automotive sectors. Secondly, fiberglass fabrics exhibit superb thermal insulation properties. They display remarkable resistance to heat and can endure high temperatures without sacrificing their structural integrity. As a result, they are suitable for applications necessitating heat resistance, including insulation materials and the construction of fire-resistant structures. Another advantage of fiberglass fabrics lies in their resistance to chemicals and corrosion. They demonstrate high resistance to various chemicals, acids, and alkalis, rendering them perfect for environments where exposure to corrosive substances is commonplace, like chemical processing plants or marine applications. Moreover, fiberglass fabrics offer high flexibility and can be effortlessly molded into diverse shapes and forms. This versatility allows for a wide range of applications, ranging from reinforcement materials in composites to the creation of intricate structures in architectural design. Furthermore, fiberglass fabrics are non-conductive and boast excellent electrical insulation properties. Consequently, they are well-suited for electrical applications that require insulation to prevent electric shocks or short circuits. Lastly, fiberglass fabrics are relatively cost-effective compared to other high-performance materials like carbon fiber. They deliver similar properties at a more affordable price, making them a popular choice in industries that prioritize cost-effectiveness. In conclusion, the benefits of utilizing fiberglass fabrics include their impressive strength-to-weight ratio, thermal insulation properties, resistance to chemicals and corrosion, flexibility, electrical insulation properties, and cost-effectiveness. These attributes make fiberglass fabrics a versatile and dependable material for a wide range of applications in various industries.

- Q: Can fiberglass fabric be used for making insulation blankets?

- Indeed, insulation blankets can be manufactured using fiberglass fabric. Renowned for its remarkable thermal insulation qualities, fiberglass fabric proves to be a perfect material for crafting insulation blankets. These blankets are specifically engineered to confine heat and hinder its transmission, ensuring efficient insulation across diverse contexts like residential abodes, industrial environments, as well as aerospace and automotive sectors. Typically, the fiberglass fabric employed in insulation blankets is woven or knitted, rendering it supple and effortlessly modifiable to suit various shapes and dimensions. Moreover, fiberglass fabric exhibits traits of being lightweight, fireproof, and resistant to both chemicals and moisture, thereby establishing itself as a dependable option for insulation purposes.

- Q: What are the different fiberglass fabric finishes for fire resistance?

- Some common fiberglass fabric finishes for fire resistance include flame retardant, fire retardant, and heat resistant finishes. These finishes are designed to enhance the fabric's ability to resist ignition and slow down the spread of flames in case of a fire.

- Q: What are the different fiberglass fabric weaves for flexibility?

- There are several different fiberglass fabric weaves that offer flexibility, including plain weave, twill weave, satin weave, and leno weave. These weaves provide varying degrees of flexibility and each has its own unique characteristics and uses.

Send your message to us

Fiberglass Fabrics - e-glass stitich combo mat- tlx top quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords