factory price!!! Galvanized/PVC Coated Welded Wire Mesh Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

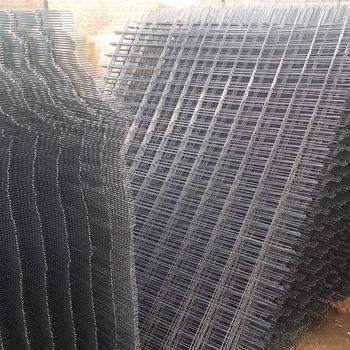

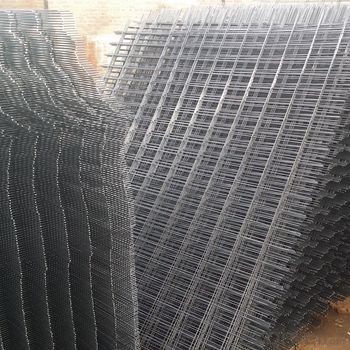

Factory price!!! galvanized/pvc coated Welded Wire Mesh Panel

1. Welded Wire Mesh Description:

Welded wire mesh is made from stainless steel wire or galvanized wire,which shows good corrosion-resistance and oxidation-resistance,widely used for poultry houses,egg baskets,runway enclosures,draining racks,porch guards,rat-proofing, safety guards on machines, animal and plant pens and shelves, etc.

2.Main Features of the Welded Wire Mesh:

smooth mesh surface ,well-proportioned meshes ,strong welded points and bright luster .The mesh doesn’t come loose even if cut in parts or being exerted force on parts .Compared with general iron wire ,the products are better in respects of anti-corrosive and anti-rust.

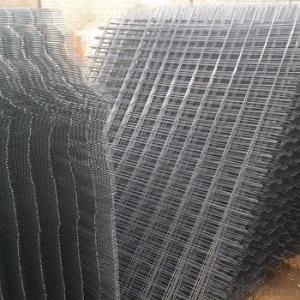

3.Welded Wire Mesh Images

4.Welded Wire Mesh Specification

Specification List of Galvanized Welded Wire Mesh: | ||

Opening | Wire Diameter | |

In inch | In metric unit(mm) | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 |

5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 |

1" x 1/2" | 25.4mm x 12.7mm | 16,17,18,19,20,21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 |

1" x 2" | 25.4mm x 50.8mm | 14,15,16 |

2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 |

Technical Note: 1.Standard roll length: 30m;width: 0.5m to 1.8m 2.Special sizes available at request | ||

Special sizes are also available.

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Australia.

(2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the applications of steel angles?

- Steel angles have a wide range of applications in various industries. They are commonly used in construction for structural framing, providing support and stability to buildings. Steel angles are also used in the manufacturing of machinery, equipment, and vehicles, where their strength and durability are crucial. Additionally, they find application in the fabrication of infrastructure such as bridges, walkways, and platforms. The versatility of steel angles makes them valuable in many other applications, including shelving, fencing, and reinforcing concrete structures.

- Q: How do steel products contribute to the infrastructure development of a country?

- Steel products contribute to the infrastructure development of a country in several ways. Firstly, steel is a versatile and durable material that is used in the construction of buildings, bridges, roads, and other vital infrastructure. Its strength and ability to withstand extreme weather conditions make it an ideal choice for these applications. Secondly, steel products such as pipes and cables are essential for the efficient transportation of water, gas, and electricity, ensuring that cities and towns have access to these vital resources. Lastly, the manufacturing and production of steel products create employment opportunities and stimulate economic growth, contributing to the overall development of a country's infrastructure.

- Q: What are the properties of stainless steel for medical applications?

- Stainless steel used in medical applications is known for its exceptional properties such as corrosion resistance, high strength, durability, and biocompatibility. These properties make it an ideal material for surgical instruments, implants, and medical devices. Additionally, stainless steel can be easily sterilized, has good formability, and allows for precise manufacturing, making it a reliable choice in the medical field.

- Q: How are steel coils used in manufacturing processes?

- Steel coils are used in manufacturing processes in various ways. They are commonly used in industries such as automotive, construction, and appliances. The coils are often unwound and fed into machinery to create different products, such as sheet metal for car bodies, structural components for buildings, or parts for household appliances. The versatility and strength of steel make it a popular choice in manufacturing, and steel coils play a crucial role in transforming raw materials into finished goods.

- Q: What are the different types of steel gratings and walkways available?

- There are several different types of steel gratings and walkways available, including welded steel grating, press-locked steel grating, and swage-locked steel grating. These gratings are commonly used for industrial flooring, catwalks, stair treads, and platforms due to their durability and strength. Additionally, there are various surface treatments and finishes available for steel gratings, such as galvanization or powder coating, to enhance their corrosion resistance and aesthetics.

- Q: What are the different types of steel chains and their uses in agricultural machinery?

- There are several types of steel chains commonly used in agricultural machinery. These include roller chains, leaf chains, and agricultural chains. Roller chains are the most widely used and are commonly found in tractors, combines, and other farming equipment. They are used to transmit power from the engine to various components, such as wheels, blades, or conveyors. Leaf chains are often used in heavy-duty applications, such as in balers or harvesters, where they provide reliable lifting and pulling capabilities. Agricultural chains, on the other hand, are designed specifically for agricultural machinery and are used for tasks like crop harvesting, sowing, or irrigation. These chains are usually resistant to corrosion and wear, making them suitable for outdoor and demanding conditions.

- Q: How is steel used in the production of construction machinery?

- Steel is commonly used in the production of construction machinery due to its high strength, durability, and resistance to wear and tear. It is utilized in various components, such as the machine's frame, chassis, and structural elements, to provide the necessary strength and stability required for heavy-duty construction tasks. Additionally, steel is often employed in the manufacturing of buckets, blades, and other attachments, as it can withstand the demanding conditions and intense forces typically encountered in construction projects.

- Q: How is steel used in the manufacturing of storage tanks?

- Steel is commonly used in the manufacturing of storage tanks due to its durability, strength, and resistance to corrosion. It provides a sturdy structure that can withstand high pressures and extreme weather conditions. Steel tanks can be fabricated in various sizes and shapes to accommodate different storage needs, making them versatile for storing various substances such as water, oil, chemicals, and gases.

- Q: What are the different types of steel doors and windows?

- There are several different types of steel doors and windows, including flush doors, panel doors, sliding doors, casement windows, and fixed windows.

- Q: What are the uses of steel in the construction of shopping malls and retail centers?

- Steel is extensively used in the construction of shopping malls and retail centers due to its exceptional strength and durability. It provides structural support for large open spaces, allowing for flexible and customizable designs. Steel beams and columns are also used to create intricate facades and can support the weight of multiple floors. Additionally, steel is fire-resistant, ensuring the safety of occupants. Overall, steel plays a crucial role in creating safe, functional, and visually appealing shopping environments.

Send your message to us

factory price!!! Galvanized/PVC Coated Welded Wire Mesh Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords