Higher Finishing Surface CRC Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

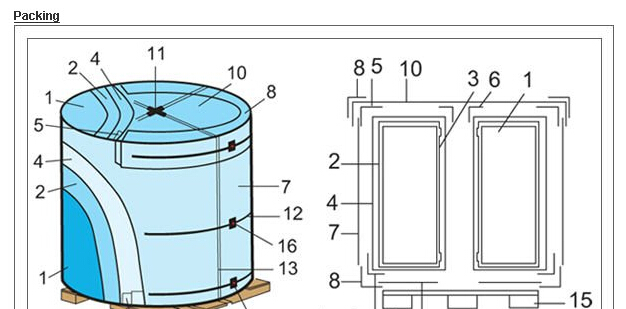

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508&610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

DC01 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

DC03 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

DC04 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: What are the different types of steel cables and ropes?

- There are various types of steel cables and ropes available, including wire ropes, galvanized steel cables, stainless steel cables, and aircraft cables. Each type has its own specific uses and characteristics. Wire ropes are made up of multiple strands of wire twisted together and are commonly used for lifting heavy loads. Galvanized steel cables are coated with zinc to enhance corrosion resistance and are often used in outdoor and marine applications. Stainless steel cables are highly resistant to rust and corrosion, making them suitable for harsh environments. Aircraft cables are specifically designed for aviation and aerospace applications, known for their strength and flexibility.

- Q: How is steel used in the manufacturing of consumer goods?

- Steel is used in the manufacturing of consumer goods in various ways, such as in the production of appliances, automobiles, furniture, and packaging materials. It is valued for its strength, durability, and versatility, allowing manufacturers to create sturdy and long-lasting products. Whether it's the frame of a car, the casing of a refrigerator, or the structure of a piece of furniture, steel plays a crucial role in ensuring the quality and reliability of consumer goods.

- Q: How do steel products contribute to the construction of hospitals and healthcare facilities?

- Steel products play a crucial role in the construction of hospitals and healthcare facilities. They are used in various applications, such as structural frameworks, support beams, and roofing systems. Steel's strength and durability ensure the safety and stability of these structures, making them capable of withstanding heavy loads and adverse weather conditions. Additionally, steel's versatility allows for flexible building designs and the incorporation of advanced technologies, such as medical equipment and electrical systems. Overall, steel products are essential in creating reliable, efficient, and modern healthcare facilities that can provide high-quality medical care to patients.

- Q: How is steel wire used in the production of cables?

- Steel wire is commonly used in the production of cables as a strength member or reinforcement. It provides structural integrity and durability, allowing the cable to withstand tension and prevent stretching or breaking. Steel wire is typically used in power cables, suspension bridges, elevator cables, and various other applications where strength and reliability are essential.

- Q: What are the different types of steel rails and their applications in railways?

- There are several types of steel rails used in railways, including plain carbon steel rails, heat-treated carbon steel rails, and alloy steel rails. Plain carbon steel rails are the most commonly used type and are suitable for most railway applications. They have good strength, durability, and wear resistance. Heat-treated carbon steel rails undergo a heat treatment process to improve their hardness and strength. These rails are used in high-traffic areas, such as mainline tracks, where they can withstand heavy loads and minimize wear. Alloy steel rails contain additional elements like manganese, chromium, and nickel, which enhance their strength and corrosion resistance. These rails are used in harsh environments, such as coastal areas, where there is a higher risk of corrosion. The choice of steel rail depends on factors like the railway's traffic volume, speed, and environmental conditions. By selecting the appropriate type of steel rail, railways can ensure safety, reliability, and longevity of their tracks.

- Q: What are the different types of steel brackets and their uses?

- There are several types of steel brackets with varying designs and uses. Some common types include L brackets, corner brackets, T brackets, and U brackets. L brackets are used for providing support and stability in various applications such as shelving, furniture, and construction projects. Corner brackets are specifically designed to reinforce corners and joints, often used in furniture construction or framing. T brackets are used to join two pieces of material at a right angle, commonly found in building frames or brackets for shelves. U brackets, also known as channel brackets, are used to secure or hold objects in place, often seen in electrical or plumbing installations. Overall, steel brackets provide structural support and reinforcement in a wide range of applications.

- Q: What are the different types of steel beams and their applications?

- There are several types of steel beams used in construction and their applications vary based on their shape and properties. Some common types include I-beams, H-beams, and C-beams. I-beams are commonly used in structural applications, such as for supporting heavy loads and spanning long distances. H-beams are often used in residential and commercial construction for their strength and versatility. C-beams, also known as channel beams, are commonly used in applications where lightweight structural support is needed, such as in the construction of bridges or mezzanines. Overall, the choice of steel beam depends on the specific requirements of the project and the load-bearing capacity needed.

- Q: How does steel pipe threading for fire sprinkler systems work?

- Steel pipe threading for fire sprinkler systems involves the process of cutting grooves into steel pipes to create a threaded connection. This threading is done using a specialized machine called a pipe threader. The threaded connection allows the individual pipes to be easily joined together, ensuring a secure and leak-proof connection.

- Q: What are the different types of steel roofing systems?

- There are several types of steel roofing systems, including standing seam, corrugated, and metal shingle roofs.

- Q: How are steel products used in the manufacturing of furniture?

- Steel products are used in the manufacturing of furniture as structural components, such as frames, legs, and supports. Steel's strength and durability make it an ideal material for ensuring stability and longevity in furniture. Additionally, steel can be shaped and welded into various designs, allowing for versatile and modern furniture styles.

Send your message to us

Higher Finishing Surface CRC Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords