Hot-dip Aluzinc Steel Building Roof Sheet in Coils of Prime Quality 0.29mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

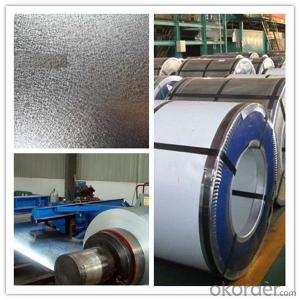

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S250GD+AZ S280GD+AZ S550GD+AZ | SGLC440 SGLC490 SGLC570 |

2.5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

3.Could you let me approach about your company in Dubai?

Located at Jebel Ali Free Zone in Dubai, CNBM Dubai Logistics Complex is adjacent to -Jebel Ali sea port-the largest port in UAE and Al Maktoum Airport-the largest airport in the world, which covers an area of 50,000 square meters, including an fully enclosed warehouse by 10,000 square meters, an open yard by 25000 square meters, and 13 standard unloading platform. CNBM Dubai Logistics Complex formally put into operation on August 1, 2013. Dubai Logistics Complex will commit itself to build the most professional and most influential building materials distribution center of China’s building materials industry in the UAE and throughout the Middle East and Africa.

- Q: What are the different types of steel railway products available?

- There are several types of steel railway products available, including rails, sleepers, fasteners, and switches. Rails are the main component of railway tracks and come in different sizes and profiles. Sleepers, also known as ties, provide support to the rails and come in various materials such as concrete, wood, and steel. Fasteners, such as clips and bolts, are used to secure the rails to the sleepers. Switches, also called turnouts, allow trains to change tracks and come in different configurations.

- Q: How are steel billets produced?

- Steel billets are produced through a process called casting, where molten steel is poured into molds and then cooled and solidified to form rectangular or square-shaped blocks. These billets are then further processed through rolling or extrusion to create various steel products.

- Q: How is steel wire galvanized for fencing applications?

- Steel wire is galvanized for fencing applications by immersing it in a bath of molten zinc. This process, known as hot-dip galvanizing, forms a protective zinc coating on the wire's surface, which helps prevent corrosion and extends its lifespan.

- Q: What are the different types of steel beams?

- There are several different types of steel beams, including I-beams, H-beams, W-beams, and channel beams. Each type of beam has its own specific shape and dimensions, making them suitable for different structural applications.

- Q: What are the different types of steel bars and rods available?

- There are several different types of steel bars and rods available, including carbon steel bars, alloy steel bars, stainless steel bars, and tool steel bars. Each type has its own unique properties and is used in various applications depending on their strength, corrosion resistance, and machinability requirements.

- Q: What are the different types of steel wires and their applications in the automotive industry?

- There are several types of steel wires used in the automotive industry, each with its specific applications. Some common types include high carbon steel wire, stainless steel wire, and galvanized steel wire. High carbon steel wire is known for its strength and durability, making it suitable for applications in the suspension system, seat frames, and brake systems. Stainless steel wire, on the other hand, provides excellent corrosion resistance and is often used in exhaust systems, fuel lines, and other components that are exposed to harsh environments. Galvanized steel wire is coated with a protective layer of zinc, making it resistant to rust and corrosion. This type of wire is commonly used in applications such as springs, cables, and reinforcements for various automotive parts. Overall, steel wires play a crucial role in enhancing the strength, stability, and safety of automotive components, contributing to the overall performance and reliability of vehicles.

- Q: What are the properties of corrosion-resistant steel for marine applications?

- Corrosion-resistant steel for marine applications possesses properties such as high levels of chromium and nickel, which provide excellent resistance to corrosion caused by saltwater exposure. It also has a protective oxide layer that forms on the surface, preventing further oxidation. Additionally, it exhibits high strength and durability, making it ideal for withstanding harsh marine environments.

- Q: How are steel products used in the water treatment industry?

- Steel products are used in the water treatment industry for various purposes such as the construction of water tanks, pipelines, and treatment equipment. They provide durability, corrosion resistance, and strength, ensuring a reliable infrastructure for storing, transporting, and treating water.

- Q: What are the advantages of using steel in roofing materials?

- There are several advantages to using steel in roofing materials. Firstly, steel is known for its durability and strength, making it highly resistant to harsh weather conditions such as extreme temperatures, heavy rain, snow, and strong winds. This durability ensures that steel roofs have a longer lifespan compared to other roofing materials, reducing the need for frequent repairs or replacements. Additionally, steel roofs are fire-resistant, providing an extra layer of safety to the building. Steel is also lightweight, which makes it easier and cheaper to transport and install. Moreover, steel roofing materials are available in a variety of colors and styles, allowing for customization to match the aesthetic preferences of the building owner. Lastly, steel is an environmentally friendly choice as it is recyclable, reducing the impact on the environment and promoting sustainability. Overall, the advantages of using steel in roofing materials make it a popular and practical choice for many buildings.

- Q: How do steel products contribute to the construction of theme-based culinary experience centers?

- Steel products contribute to the construction of theme-based culinary experience centers by providing structural support and durability to the buildings. Steel beams, columns, and frames are used to create the framework of the centers, ensuring stability and safety. Additionally, steel is often used for the fabrication of kitchen equipment, such as countertops, shelves, and cooking appliances. Its strength and resistance to heat and corrosion make it an ideal material for creating a functional and aesthetically pleasing culinary environment.

Send your message to us

Hot-dip Aluzinc Steel Building Roof Sheet in Coils of Prime Quality 0.29mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords