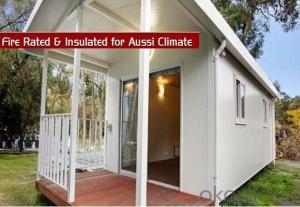

Export to Africa Container House Outdoor Panel House

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is eps sandwich wall panel?

Sandwich panel is currently in a common building material products, has two layer of metal panels and middle polymer insulated core repression. Forming an outer steel account of the structure and strength requirements, taking into account the appearance, the inner surface layer is formed into a flat to suit a variety of needs. Filling system used is closed cell molecular structure, Can prevent moisture condensation.

Detailed introduction to EPS house:

1 Structure is reliable :Light steel structure system is safe and reliable ,satisfied modern architecture concept.

2 Easy assembly and disassembly : The house can be assembled and disassembled many times,used repeatedly. It just need simple tools to assemble .each worker can assemble 20-30 square meters every day ,6 worker can finish 300 sqm prefab house in 2 days.

3 Beautiful decoration : the prefab house is beautiful and grace ,have bright and bland colour , flat and neat board , with good decoration effect.

4 Flexible layout : Door and window can be assembled in any position , partition wall panel can be assemble in any transverse axes sites ,stair is assembled in outside.

5 Using life : All the light steel structures have antisepsis-spraying treatment.the normal using age are above 15 years.

6 Environmental protection and economy : Prefab house design is reasonable, easy to assemble and disassemble,used circularly,low wastage,without building rubbish. Average using costing is less than other kinds of building annually.

Specification of EPS house

ITEM | SANDWICH PANEL | LENGTH THICKNESS | 950MM 50MM | ||||||

QUANTITY | 1M2 | DATE | 2013-12-4 | ||||||

ITEM | STANDARD | RESULT | MEMO | ||||||

1 | COLOR | Conformity in same batch | Conformity | Qualified | |||||

2 | CRACK | No | No | Qualified | |||||

3 | INDENTATION | Not obviously | Not obviously | Qualified | |||||

4 | SIZE | LENGTH | ±2mm | 51mm | Qualified | ||||

THICKNESS | ±20mm | 950mm | Qualified | ||||||

5 | DENSITY kg/m2 | >=10.5% | 10.8% | Qualified | |||||

6 | STRIPPING PERFORMANCE | >=85% | 87% | Qualified | |||||

7 | MPA | >0.1 | 0.11 | Qualified | |||||

CONCLUSION | Qualified | ||||||||

Note:

Our projects:

1.Price no including the transport and installation cost, no including foundation cost,floor and ceiling cost,water and electricity cost.

2.Validity: This quotation sheet is valid for 15 days due to the unstable RMB exchange rate.

3.Payment term:30% T/T deposit before production, the balance 70% T/T need to pay before delivery.

4.Packing:Flat pack.

5.Delivery time:15 days after receive the 30% deposit. (The quantity is less than 5000㎡)

6.All price not listed in above project need to calculate separately.

- Q: Cold storage installation sandwich panels need to use sealant? With much more, with polyurethane sealant or silicone glue more?

- Generally with porcelain white neutral silicone

- Q: Industrial building facades

- Even the United States outside the wall panels, search Dalian, the official website of the United States chemical building materials.

- Q: Is not allowed to use foam sandwich color plate

- Hello! Now the state banned the use of foam sandwich color steel plate, also known as foam sandwich panels, because the foam sandwich board fire rating is poor, the state is prohibited. Now the market generally use rock wool color plate, which is used instead of rock wool composite board, fire rating up to A level. There are also some high-end customers with polyurethane color plates instead of using them, so the cost may be higher. Choose a most suitable for their own sandwich color plate can be used. After all, who is not the wind to the wind, the ability to do so

- Q: EPS corrugated composite board and corrugated sandwich board What is the difference, 50MMEPS corrugated composite board (0.5 on the next 0.4) to do the plant roof construction process is how The price is almost a square?

- EPS corrugated composite board is a corrugated sandwich board, according to the core of the different corrugated sandwich panels are divided into EPS corrugated sandwich panels (that is, EPS), extruded sandwich panels, polyurethane sandwich panels and rock wool sandwich Plate and so on. Construction is the steel structure plus sandwich panels.

- Q: Color steel sandwich panel of the relevant parameters

- Product performance: thickness 0.2mm ~ 1.0mm Core thickness: 50mm ~ 250mm Effective height: 1000mm, 1200mm, 960mm.950mm Scope: workshop, office walls, steel structure of the external walls Maintenance, decorative building materials, activities, such as office buildings Fire rating: B1 ~ B3 (flame retardant: melting) Moisture absorption: 3.9 (%)

- Q: Plan to use Caigang sandwich panels to do the roof. The wall is brick wall. Ask how the sandwich panel is fixed on the brick wall ah?

- Wall to do reinforced concrete ring beam cap, and then fixed on the ring beam C-keel, sandwich plate fixed on the keel, complete.

- Q: The use of foam sandwich panels erection of the temporary board of the building components of the combustion than the A-level, to rectification, how to engage in ah

- Foam sandwich board where are lower than the A-level, but still someone use, because the convenience, the price is low, so let you rectification is to let you ask you to pay for it

- Q: Explosion-proof rock wool sandwich panel how to do waterproof

- Do a good job of waterproof coating treatment, the other is, you can in its surface, composite layer of metal, so you can better waterproof moisture Oh.

- Q: Is the factory wall with a sandwich board fire clearance?

- Yanmian, then the fire temperature can reach 700 degrees, two glass wool can only reach 260 degrees, and then there are magnesium, and now the highest fire intensity of the material.

- Q: Color steel sandwich panel has what color?

- Highland and white ashes. Special colors can be customized

Send your message to us

Export to Africa Container House Outdoor Panel House

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords