Expanded Polystyrene Sandwich Panels - Rockwool Sandwich Panel Anti-Rust with Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1. Good Thermal Insulation, an energy saving material

2. Good Fire Resistance: B1 grade for total panel

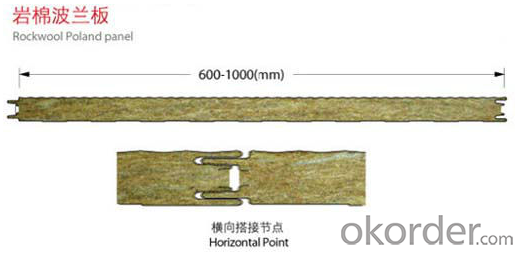

3. Special Connection Design: Screw concealed connection

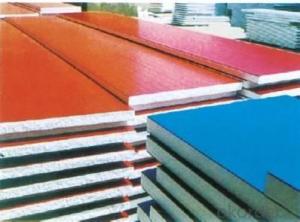

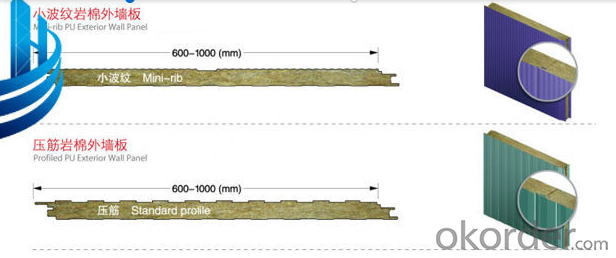

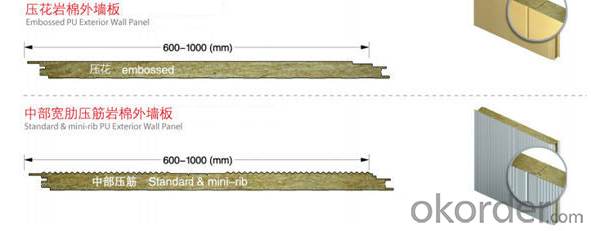

4. Graceful Finish: embossment, small wave, big rib and flat finish

5. Advance Machine: The longest main machine

6. Strict Workshop Management: TMP-5S management system

7. Raw Material: Only quality steel is selected.

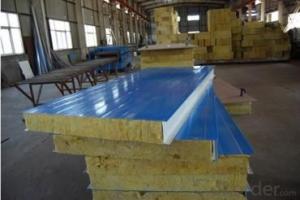

8. Wide Usage: Used as roof and wall in workshop and

Materials:

High quality. Competitive price.

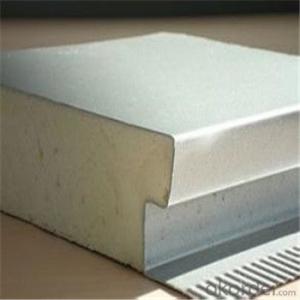

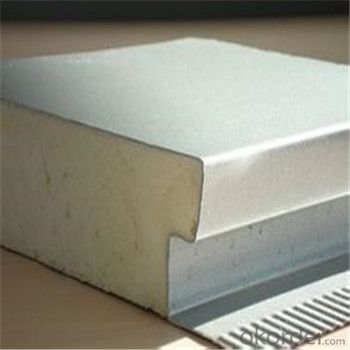

Steel Thickness | 0.3~0.6mm |

Panel thickness | 50/75/100/150/200 mm |

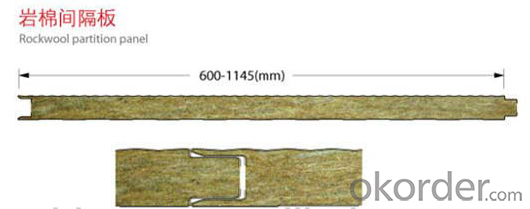

Effective width | (1) 950/mm ---for roof (2) 950/1000/1150mm---for wall or ceiling |

Length | According to customer's request,less than 11.8m |

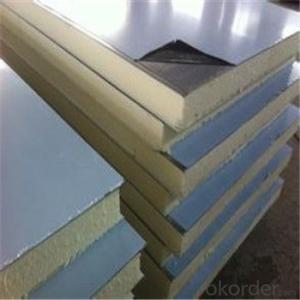

Materials | Inner is Rockwool,two sides is Color steel tile |

Structure | three layers: (1)upper layer is steel sheet, (2)the inner layer is Rock wool sandwich , (3)the bottom layer is also steel sheet |

Rockwool density |

100(kg/m³),etc

|

color | according to customer. |

Parts | Steel line for easy connect one by one Film covering in order to protect the steel of panels |

lifetime | 15~20 years |

Character | Light in weight, heat insulation, fireproof and waterproof,environmental |

Use | various roofs and walls referring to the large size factory buildings,storages, exhibition halls, gymnasiums ,etc |

Packing | Packed by shipping Container or according to your demands |

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- Color steel export tax rebate rate is 13%. Color plate width over 600mm VAT 17%. The export company 's tax rebate formula is: factory tax * 13% / 1.17. The export tax rebate rate is the ratio between the actual tax return of the exported goods and the taxable basis. It is the central part of the export tax rebate, reflecting the country in a certain period of economic policy, reflecting the actual level of export goods tax, the tax rebate rate is based on the actual export of goods to determine the overall tax burden, but also the principle of zero tax and macroeconomic regulation and control principles The product of the combination.

- Q: I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad to give you a reference, hope useful

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: Color steel room life in general how many years

- Safety information complete directory directory Chapter 1 construction site safety technical data management of the main content and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technology The establishment of the data Section IV of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (second file Box) Section III of the target management (the third file box) Section IV of the safe construction of the organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (The sixth file box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident ( The eleventh section of the security box (the eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (tenth File box) Section XII mechanical equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union Labor protection information

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. Sandwich panels are a type of construction material that consists of two outer layers (usually made of metal) with an insulating core in between. This combination of materials provides excellent thermal insulation, fire resistance, and soundproofing properties, making them ideal for train station applications. The insulation properties of sandwich panels help to regulate the temperature inside the train station, ensuring a comfortable environment for passengers and staff regardless of external weather conditions. This can help reduce energy consumption and lower heating or cooling costs. Sandwich panels are also highly fire-resistant, which is crucial for train stations where the risk of fire is a major concern due to the presence of electrical systems, passengers, and potentially flammable materials. The fire-resistant properties of sandwich panels can help contain and slow down the spread of fire, providing valuable time for evacuation and firefighting efforts. Furthermore, sandwich panels offer excellent soundproofing capabilities. Train stations are typically noisy environments due to the constant movement of trains, announcements, and passenger conversations. The use of sandwich panels can significantly reduce noise transmission, creating a more peaceful and comfortable atmosphere for passengers and staff. Additionally, sandwich panels are lightweight and easy to install, making them a cost-effective and efficient choice for train station construction or renovation projects. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are indeed suitable for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, providing a positive experience for both passengers and staff.

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- When the top of the ventilation tube can not be extended out of the roof, the following ventilation can be used: ①, set the side wall ventilation tube ②, by setting the confluence of the ventilation pipe after the extension of the side wall to extend above the roof ③, set up self-circulation ventilation pipeline system , the following circumstances should be set up ventilation riser: ①, when the drainage pipe to take the sanitary equipment drainage design flow than in Table 449 only set the top of the drainage pipe drainage pipe maximum design drainage capacity ②, the building standards require a high multi-storey residential and public buildings, 10-storey and 10-storey high-rise building life drainage riser , the following drainage pipe should be set up annular ventilation pipe: ①, connecting four and more than four sanitary ware and the length of more than 12m of the drainage pipe ②, connecting 6 and 6 or more toilet toilet cross pipe ③, do not exceed the above provisions, but the nature of the building is important, the use of high requirements or set the device when the ventilation tube , the health, quiet requirements of the building, the living drainage pipe should be set to ventilator tube , the drainage pipe at all levels of the building shall be provided with an annular ventilation pipe, and shall be provided with a main ventilation riser or a secondary ventilation riser for the connection of the layers , ventilation riser shall not accept the equipment of sewage, waste water and rain; not connected with the duct and flue

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- The price of the foam board depends on its density, the higher the density, the more expensive the price

- Q: The stove is dedicated to the plastic used for plastic paper

- Before you understand this specification, you must first understand what is the tripod

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- Pipe pressure deformation, pressure relief pipe is not restored, the clamp inside the leather pad is not restored, there may be water seepage

Send your message to us

Expanded Polystyrene Sandwich Panels - Rockwool Sandwich Panel Anti-Rust with Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords