Polyurethane (PU) Foam Sandwich Panel Composite with Aluminum Foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

CMAX PU Foam Sandwich Panel for air conditioning

CFC HCFC Free Environment Freindly

Low thermal conductivity

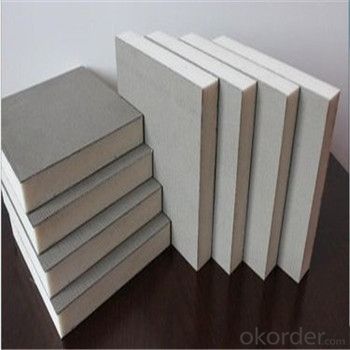

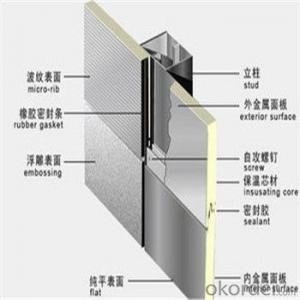

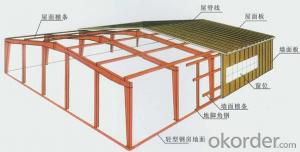

CMAX Polyurethane (PU) Foam Sandwich Panel for air conditioning is widely used for the air distribution of central air duct system, which is one of the most advanced and energy-saving air duct systems. The system is composed of CFC & HCFC free Polyurethane Foam Pre-insulated air duct panel and professional supporting accessories & tools. By taking the rigid insulation foam as the core material and covered with embossed/smooth Aluminum foil on both sides, PU Foam Pre-insulated air duct panel obtains excellent performances of low vapor permeability, thermal resistance and good toughness property, which is also environment Friendly.

Specification of Polyurethane (PU) Foam Pre-insulated Duct Panel:

Item | Unit | Specification |

Panel Structure | Alu./Foam/Alu. | |

Standard Panel Size | mm | 3950*1200*20 |

Alu. Foil Thickness | mm | 0.06 |

Alu. Foil Thickness | mm | 0.06 |

Foam Density | kg/m3 | 55 |

Thermal Conductivity | w/m.k | 0.021 |

Compressing Strength | Mpa | 0.2 |

Bending Strength | Mpa | 2 |

Water Absorption | % | ≤0.1 |

Dimension Change | % | 0.3 |

Working Temperature | °C | -100 to +80 |

Maximum Allowable Wind Velocity | m/s | ≤12 |

Continuous Running Maximum Temperature | °C | ≤70 |

Advantages of Polyurethane(PU) Pre-insulated HVAC Ductwork:

1. Lower heat conductivity, higher thermal efficiency

2. Low density, light weight

3. Foamed with CFC free materials, environment protective

4. Hermetic seal ensures little air leakage

5. With aluminum foil reinforced on both sides, its corrosion protective, hygeian, and has a beautiful appearance.

6. Foamed with closed-cell structure, its water-proof and sound-insulated.

7. Easy making, rapid installing and convenient maintenance saves cost.

8. No protrudent flange on the connections, it can save a lot of building space.

FAQ:

1. Could be changed the size of the panel?

Yes, according to your requirement.

2. What is the minimum production?

4000 m2 x 1day x 8 hours.

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- The system after spraying the rigid foam polyurethane insulation layer in the wall to form a continuous seamless overall, winter can avoid the heat bridge, greatly reduce the indoor heat loss; summer can greatly reduce the sun due to the external walls of the heat conduction, and then So that heating, air conditioning, energy consumption, energy saving effect is obvious, can reduce energy consumption, protect the theme structure, to extend the life of the building

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- It should be, for example, naphthalene anthracene, and several rings are capable of forming a closed conjugate system. Generally speaking, more than four benzene rings are fused (for example, 1.2-benzo, 3-methyl Anthracene, etc.) are mostly carcinogenic substances, which are mostly anthracene derivatives, the relationship between the mechanism of carcinogenesis and structure is not yet fully understood ...

- Q: Reinforced concrete and metal sandwich board how much difference

- Tower crane driver, scaffolding type of work, all kinds of welding workers

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- The wall is relatively smooth, the external wall insulation per square meter with the mortar 4-foot often end of the shop to the whole shop 6 kg foot; wall is the wall, more mortar, a square need 7-9 kg

- Q: Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are commonly used in the construction of food kiosks due to their durability, insulation properties, and ease of installation. They provide a hygienic and easy-to-maintain surface, making them ideal for food-related businesses. Additionally, sandwich panels offer flexibility in design and can be customized to meet specific requirements, making them a popular choice for food kiosks.

- Q: How does the wall rock wool sandwich panel be installed?

- the basis for the preparation (the relevant laws and regulations, standards, construction drawings, computing software, etc

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are made up of two thin outer layers with a thermal insulating core material in between. They are known for their strength, durability, and energy efficiency. These properties make them an ideal choice for various construction applications, including ticket booths. Sandwich panels can provide insulation against extreme temperatures, noise reduction, and fire resistance, which are important features for ticket booths. Additionally, sandwich panels are lightweight, making them easy to transport and install. They can also be customized to fit specific design requirements and can be easily maintained. Therefore, sandwich panels are a suitable and practical option for ticket booths.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- Buy the quality of a little bit of what the material is no problem, although the price is more expensive, but the first safety is important

- Q: 50mm thickness of color steel foam sandwich board how much money a flat

- To strengthen safety education, training and safety technology. Article 4 Special operations personnel shall, after obtaining the Special Operations Operation Certificate, carry out the corresponding work; the construction unit shall not arrange for the operating personnel who have not obtained the "special operation operation certificate" to engage in special types of work. Article 5 Special operations personnel shall strictly implement the special operating procedures and the relevant safety rules and regulations, according to the chapter operation, refused to illegal command. Article 6 special operations personnel should carry their own documents, consciously accept the employer, the safety management department of the supervision and inspection. Article VII of the special operations personnel operations, the accident hidden or insecurity factors, should be to the site safety management and the relevant person in charge of the report.

- Q: The stove is dedicated to the plastic used for plastic paper

- It is best not to sleep so, first bubble is airtight! The skin is very bad, long-term will also affect the health

Send your message to us

Polyurethane (PU) Foam Sandwich Panel Composite with Aluminum Foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords