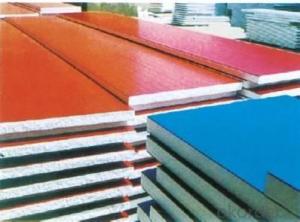

Expanded Polystyrene Sandwich Panels - Fire Resistance Rock Wool Foam Sandwich Panel for Wall and Roof Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

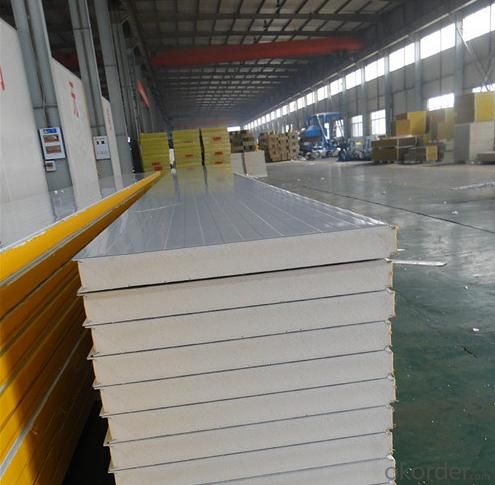

Packaging & Delivery

| Packaging Detail: | 1.Free packing (with normal pallet and packing belt) 2.Standard exporting packing (wrapped with plastic thin film,edge protect and good pallet) 3.Standard exporting packing (With plastic thin film,wdge protected and good pallet) |

| Delivery Detail: | within 20 days |

Specifications

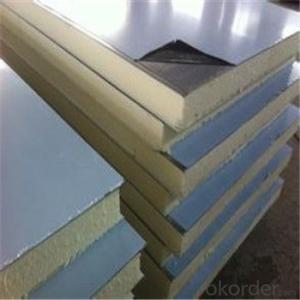

1. rock wool sandwich panel

2. Insulative & Acoustic

3. Waterproof & Airtight

4. Durable

5. Best Quality & Service

rock wool sandwich panel

1. Effective width: 950/1150mm

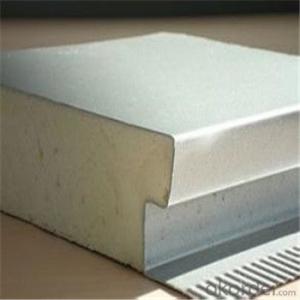

2.Thickness for rockwool: 50-150mm, normal size is: 50/75/100mm

3.Thickness for steel sheet: 0.3-0.8mm (double faces)

4. Length: according to your request, less than 12000mm suitable for the transport

5. Rockwool density: 100-150kg/m3

6. Character:

1). Fireproof, heat insulation, water resistant, noise-absorbing, cheap in price.

2). Fire resistance rating: Grade A

Specification:

950/1150 rock wool sandwich wall panel | ||

Dimensions | Total thickness | 50, 75, 100, 120, 150, 200mm |

Width | 950/1150mm | |

Length | Less than 11.8m | |

External face | Material | Pre-painted galvanised steel (ppgi) |

Thickness | 0.18-0.6mm | |

Zinc coating | 80g/m2 | |

Corrosion protection | Galvanized | |

Coating | Polyester | |

Thickness of coating | 20µm | |

Color | According to the RAL | |

Patten | Nearly plain | |

Insulation | Material | Rock wool |

Thickness | 50 75 100 120 150 200 mm | |

Density | 100-150kg/m3 | |

Thermal conductivity | </=0.044w/m.k | |

Fire rating | A grade | |

Water absorption | 3.9% | |

Shrink temperature | 643°C | |

Content organics | 2.9% | |

Internal face | Material | ppgi |

Thickness | 0.18-0.6mm | |

Zinc coating | 80g/m2 | |

Corrosion protection | Galvanized | |

Coating | Polyester | |

Thickness of coating | 5µm | |

Color | According to RAL | |

Patten | Nearly plain | |

Shipping terms | Package | Craft paper and wooden pallet |

Delivery time | Within 15-20 days after the deposit received | |

Rock wool insulation performance

| Density | Thickness | Width | Thermal Conductivity-K | Thermal Resistance-R |

| Kg/m3 | mm | m | W/m.K | m2.K/W |

| 60 | 50 | 1.2 | 0.044 | 1.14 |

| 60 | 75 | 1.2 | 0.044 | 1.71 |

| 60 | 100 | 1.2 | 0.044 | 2.27 |

| 80 | 50 | 1.2 | 0.044 | 1.14 |

| 80 | 75 | 1.2 | 0.044 | 1.71 |

| 80 | 100 | 1.2 | 0.044 | 2.27 |

| 100 | 50 | 1.2 | 0.043 | 1.16 |

| 100 | 75 | 1.2 | 0.043 | 1.74 |

| 100 | 100 | 1.2 | 0.043 | 2.33 |

| 120 | 50 | 1.2 | 0.043 | 1.16 |

| 120 | 75 | 1.2 | 0.043 | 1.74 |

| 120 | 100 | 1.2 | 0.043 | 2.33 |

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- (Including: Fluorocarbon metal paint, fluorocarbon solid paint, real stone paint, imitation stone paint, granite, relief supporting, imitation brick texture, texture matching, etc) and insulation materials series (including: XPS , EPS, PUR, phenolic board, rock wool board, ultra-thin insulation board), for the old and new concrete, steel structure, real brick wall, hollow brick wall, brick wall wall, combined with the company to install patent, Construction of the wall installation TDD insulation decorative board is not only suitable for the new building exterior insulation and decoration, but also for the old building of low-carbon energy-saving decorative transformation, and not affected by regional differences

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Foam benzene board capacity of not less than 18kg, other indicators in line with national regulations

- Q: I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- Easy to install, to prevent future loss is not tied

- Q: Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are commonly used in the construction of food kiosks due to their durability, insulation properties, and ease of installation. They provide a hygienic and easy-to-maintain surface, making them ideal for food-related businesses. Additionally, sandwich panels offer flexibility in design and can be customized to meet specific requirements, making them a popular choice for food kiosks.

- Q: General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Wall insulation is an important part of the work of home insulation, divided into external wall insulation and internal wall insulation two, the amount of internal wall insulation works much smaller than the external wall insulation, Xiaobian today to share the advantages and disadvantages of various interior wall insulation materials The Polystyrene foam board polystyrene foam board is one of the three common wall insulation materials

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. They are lightweight, strong, and provide excellent insulation properties. Additionally, sandwich panels can be easily installed and offer a wide range of design options, making them a practical and efficient choice for train station construction.

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are made up of two thin outer layers with a thermal insulating core material in between. They are known for their strength, durability, and energy efficiency. These properties make them an ideal choice for various construction applications, including ticket booths. Sandwich panels can provide insulation against extreme temperatures, noise reduction, and fire resistance, which are important features for ticket booths. Additionally, sandwich panels are lightweight, making them easy to transport and install. They can also be customized to fit specific design requirements and can be easily maintained. Therefore, sandwich panels are a suitable and practical option for ticket booths.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

Send your message to us

Expanded Polystyrene Sandwich Panels - Fire Resistance Rock Wool Foam Sandwich Panel for Wall and Roof Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords