Rock Wool Composite Sandwich Panel Best Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panels are used in those applications where high structural rigidity and low weight is required. An evident example of use of sandwich panels is aircraft where mechanical performance and weight saving is essential. Other applications include packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards), transportation and automotive as well as building & construction.

Specifications

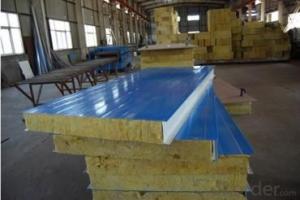

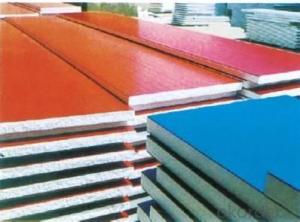

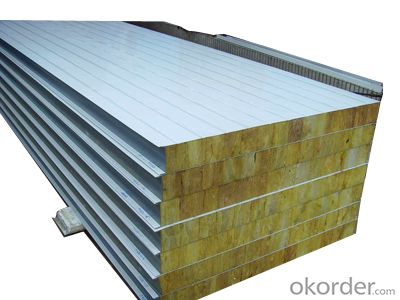

rock wool composite sandwich panel

1. Light weight

2.Excellent sound and heat insulation

3. Excellent fireproof

Product Description

The Characteristics of our Rock Wool sandwich panels

Light weight

Excellent sound insulation and heat insulation

Easy installation

Fireproof and water proof

Long life:10-15years

Beautiful appearance

The specification of our Rock Wool Color Steel Sandwich Panels

Item Data

Effective Width: 1150MM/960MM/950MM

Length: Can be customized

Materials: Rock Wool, Color steel sheet

Structure: Upper and lower layer: Color steel sheet

Middle: Rock Wool

Density of Rock Wool: 80-300KG/M3

Thickness of color steel sheet: 0.3-0.8MM

Thickness of Rock Wool: 50-250MM

Colors: Blue, white or according to your requirements

- Q: Can steel sheets be used for transportation applications?

- Transportation applications can indeed make use of steel sheets. Steel has gained immense popularity in the automotive and aerospace sectors owing to its exceptional strength, durability, and resistance to corrosion. Chassis, body panels, doors, and structural parts in various transportation components are often constructed using steel sheets. These sheets offer remarkable structural integrity and can endure substantial loads, making them ideal for vehicles and aircraft. Moreover, steel sheets can be effortlessly shaped, welded, and machined, enabling customization and efficient manufacturing procedures.

- Q: Are steel sheets suitable for data center infrastructure?

- Indeed, data center infrastructure can rely on steel sheets. The utilization of steel sheets in the establishment of data centers is prevalent because of their exceptional robustness, longevity, and resistance to fire. Furthermore, they furnish essential support for the infrastructure, encompassing server racks, cabinets, and raised flooring systems. Not only do steel sheets safeguard data center equipment against potential dangers such as electromagnetic interference (EMI) and physical harm, but they can also be conveniently tailored and adapted to suit the precise demands of a data center. This adaptability renders them a favored option for constructing data center infrastructure.

- Q: Can steel sheets be used for furniture manufacturing?

- Certainly, furniture manufacturing can utilize steel sheets. Steel, being a versatile and durable material, lends itself well to shaping and forming into various furniture components, including table legs, frames, and shelves. The strength, stability, and sleek appearance of steel sheets make them a commonly chosen option for producing modern and industrial-style furniture. Moreover, steel offers easy customization through welding, bending, or cutting, enabling the creation of personalized furniture designs. By incorporating steel sheets, furniture manufacturers gain advantages such as resistance to corrosion, fire, and pests. Consequently, steel sheets have become a favored choice among furniture manufacturers aiming to craft contemporary, sturdy, and enduring furniture pieces.

- Q: What is the reflectivity of steel sheets?

- The reflectivity of steel sheets can vary depending on factors such as the type of steel, its surface finish, and the angle of incidence of light. In general, steel sheets have a moderate to high reflectivity, especially when polished or coated. However, they are not as reflective as materials like silver or aluminum.

- Q: How can steel plates with a thickness of 1MM be welded?

- Spot welding is the welding joints in the contact surface of the individual points are welded together. The metal spot welding have better ductility. When welding, the welding surface is clean, then by sheet lap welding assembly, pressure between two cylindrical copper electrode, pressing force applied by means of the current. Large enough, resulting in a large number of heat resistance at the contact plate, the center of the hottest areas of the metals quickly heated to high plasticity or melting state, the molten pool formed a lens shaped. To keep the pressure off the current, the metal cools, forming a solder joint.

- Q: How do steel sheets perform in terms of electrical resistance?

- Compared to other materials, steel sheets exhibit a comparatively higher electrical resistance. Consequently, their conductivity falls short in comparison to metals such as copper or aluminum. The electrical resistance of steel sheets may fluctuate depending on variables like the sheet's composition and thickness. Generally speaking, steel sheets are regarded as inadequate conductors of electricity. Nevertheless, it is crucial to acknowledge that the application of specific coatings or treatments to the steel surface can diminish the electrical resistance.

- Q: How do I print the steel plate?

- In fact, the printing mode called "stencil printing", is a kind of porous printing, first use the typewriter in special Lazhi typing, or a stylus paint word pictures, and then let the wax paper attached to ordinary paper, ink in the painted pattern, through hole type or writing, and printing to the following the common paper.

- Q: How do steel sheets perform in terms of abrasion resistance?

- Steel sheets generally have good abrasion resistance due to their hardness and durability. They can withstand friction and wear caused by rubbing or scraping against other surfaces, making them suitable for applications requiring resistance to wear, such as in construction, manufacturing, and automotive industries.

- Q: Can steel sheets be used in construction projects?

- Yes, steel sheets can be commonly used in construction projects. They are versatile, durable, and provide strength and stability to structures. Steel sheets are often used for roofing, flooring, walls, and various structural components in buildings.

- Q: What are the different sheet metal forming techniques for steel sheets?

- There are several sheet metal forming techniques for steel sheets, including bending, deep drawing, punching, shearing, and roll forming.

Send your message to us

Rock Wool Composite Sandwich Panel Best Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords