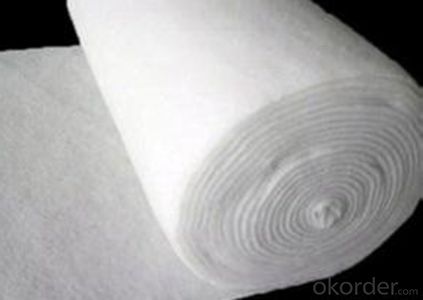

Geotextile Class 1 Excellent Filament Spunbond Needle Non-Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product introduction:

| Name | Filament spunbond needle non-woven geotextile |

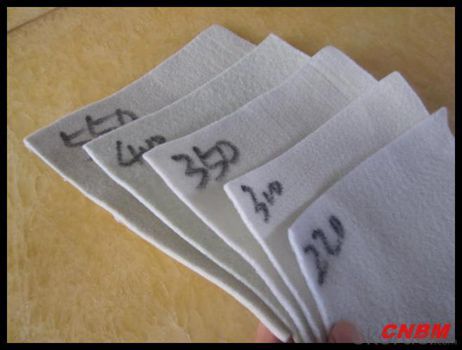

General Specifications | 100G/M2—800 G/M2 |

Product Description | Filament geotextile is used directly spinning air into the network (referred to as spunbond method) made by the acupuncture consolidation, product specifications from the 100-800g/m2 arbitrary choice, it is the application of geotechnical engineering and civil engineering as a geosynthetics. Because it is through the polyester filament into a network and the consolidation method of acupuncture made its fibers are arranged in three-dimensional structure, in addition to good mechanical properties, with a wide aperture range, tortuous pore distribution, excellent penetration and filtration good longitudinal and lateral extension of the drainage performance and good performance, also has a high resistance to bio-, acid and alkali, anti-aging properties of chemical stability. |

Usage | Used in irrigation, dikes, roads, railway embankments, landfill, Wai-hoi, tunnels and other municipal and infrastructure construction projects, reinforced the role of play in the project, isolation layer, filtering, drainage and so on. |

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: The properties of woven geotextiles

- Product features: 1, with a reinforcement function: to stabilize the project in the course of prolonged use of the transfer occurred, and can be the role of the soil in the local stress transmission or assigned to a larger area. 2, with the role of separation: woven geotextile with different geotechnical structure to form a stable interface, in accordance with the requirements to play their own characteristics and the overall role. 3, the role of drainage filter: allow moisture to block the loss of sand particles, in the drainage of geotextiles on the poor water in the soil can play the water along the geotextile quickly discharged the purpose. 4, the geotextile and geomembrane used in two different pressures between the material can play a role in tension diaphragm. 5, with a block function: the geotextile placed in the flow of liquid with suspended particles in the channel to organize fine mud particles, and allow the liquid through the function. 6, play the role of cushion mat: the geotextile placed on the slope can prevent the soil particles due to the erosion of rain and the loss or planting turf.

- Q: What are the cost considerations for geotextiles?

- The cost considerations for geotextiles depend on factors such as the type and quality of the geotextile, the required strength and durability, the size of the project, and the installation method. Generally, higher-quality geotextiles with better performance characteristics tend to be more expensive. Additionally, the quantity of geotextile required for a project and the labor costs associated with installation can significantly impact the overall cost. Therefore, it is essential to carefully analyze the specific needs of the project and compare prices from different suppliers to make an informed decision.

- Q: What are the different types of geotextile seams?

- There are several types of geotextile seams, including butt seams, overlap seams, and sewn seams. Butt seams involve joining two edges of geotextile together with an adhesive or heat bonding. Overlap seams are created by overlapping two layers of geotextile and securing them with adhesive or stitching. Sewn seams are made by stitching two layers of geotextile together with a sewing machine. Each type of seam has its own advantages and is suitable for different applications.

- Q: Geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: What are the design considerations for geotextile-reinforced pavement systems?

- Some of the key design considerations for geotextile-reinforced pavement systems include selecting the appropriate type and quality of geotextile, determining the required reinforcement strength, considering the expected traffic loads and patterns, evaluating the subgrade conditions, ensuring proper installation and compaction of the geotextile, and assessing long-term durability and maintenance requirements. Additionally, factors such as drainage, stability, and environmental impact should also be taken into account during the design process.

- Q: How do geotextiles help with reinforcement of geogrids?

- Geotextiles help with reinforcement of geogrids by acting as a separation layer between the geogrid and the surrounding soil or aggregate. This separation prevents the intrusion of fine particles into the geogrid, which could reduce its effectiveness in providing reinforcement. Additionally, geotextiles provide additional tensile strength and distribute loads more evenly across the geogrid, enhancing its overall performance and durability.

- Q: What are the different geotextile permeability testing standards?

- Some of the different geotextile permeability testing standards include ASTM D4491, ISO 11058, and EN ISO 12958. These standards provide guidelines for conducting tests to determine the hydraulic conductivity and permeability characteristics of geotextile materials.

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by providing a barrier that separates soil layers and prevents them from being washed away by water or wind. They stabilize the soil, promote vegetation growth, and enhance drainage, ultimately reducing erosion and maintaining the integrity of the landscape.

- Q: Can geotextiles be used in seawall construction?

- Yes, geotextiles can be used in seawall construction. Geotextiles are commonly used as a reinforcing material in seawalls to provide additional strength and stability. They help control erosion, prevent soil movement, and provide filtration to ensure proper drainage in seawall structures.

- Q: Are geotextiles resistant to fungal growth?

- Yes, geotextiles are generally resistant to fungal growth due to their synthetic nature and non-biodegradable properties. This resistance helps maintain their structural integrity and effectiveness in various applications.

Send your message to us

Geotextile Class 1 Excellent Filament Spunbond Needle Non-Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords