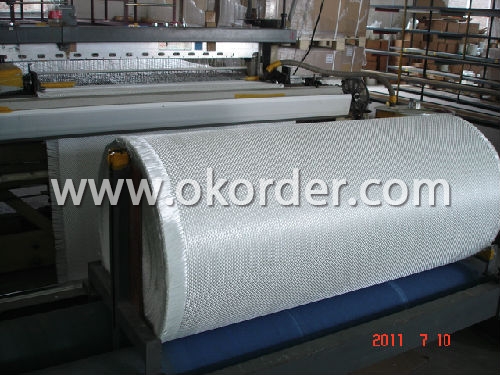

Ewr400 Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications OF EWR400

1. Low Fuzz,dirt,impurity and other stains.

2. Fast wet-out.

3. Even thickness

4.Good covering

5.Passed ISO9001,ISO14001

Characteristics of EWR400

Woven Roving is a high –performance reinforcement widely used in hand lay-up and machanical production

1) Good moldability & drapability

2) High strength

3) Excellent rollout characteristics

4) Fast wet -out

Application OF EWR400

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: Can fiberglass fabric be used for architectural applications?

- Certainly, architectural applications can make use of fiberglass fabric. This adaptable material presents several advantages for architectural projects. Its lightweight nature, flexibility, and exceptional tensile strength make it ideal for a range of applications, including roofing, cladding, and insulation. Moreover, fiberglass fabric's durability and longevity are enhanced by its resistance to fire, chemicals, and UV rays. Its ability to be effortlessly molded into intricate shapes further allows architects to conceive distinctive designs and structures. In conclusion, the manifold benefits and versatility of fiberglass fabric establish it as a favored option for architectural applications.

- Q: What is the difference between non-woven fabrics, glass fiber cloth and geotextile?

- The exact name of the non-woven fabric shall be nonwoven or non-woven. Because it is a kind of form that does not require spinning weaving fabric, just a textile fiber or filament aligned or random, the formation of the fiber network structure, and then the mechanical, thermal or chemical methods and strengthening into. Nonwovens break through the traditional textile principle, and have the characteristics of short process flow, fast production, high yield, low cost, wide use and many sources of raw materials.

- Q: Is fiberglass fabric resistant to birds?

- No, fiberglass fabric is not inherently resistant to birds. While fiberglass is a strong and durable material, it can still be damaged by birds. They may peck at or scratch the surface of the fabric, causing minor to moderate damage. Additionally, birds may build nests using fiberglass fabric if they find it suitable for their needs. However, fiberglass fabric is not a preferred material for birds as it lacks the softness and flexibility they typically seek for nesting. Therefore, while it may not be completely resistant to birds, fiberglass fabric is less likely to be heavily targeted or extensively damaged by them compared to other materials.

- Q: Can fiberglass fabric be used for clothing?

- Yes, fiberglass fabric can be used for clothing, but it is not a common or popular choice for everyday clothing. Fiberglass fabric is primarily used in industries such as aerospace, automotive, and construction due to its unique properties. It is known for its high strength, durability, and heat resistance. While these properties make fiberglass fabric suitable for protective clothing in certain professional settings, such as firefighting or welding, it is not ideal for regular clothing due to its stiffness and potential discomfort against the skin. Additionally, fiberglass fabric is not very breathable and does not provide insulation, which further limits its suitability for clothing purposes. Instead, clothing materials such as cotton, wool, silk, and synthetic fibers like polyester or nylon are more commonly used due to their comfort, breathability, flexibility, and aesthetic qualities. These materials offer a wider range of options for fashion and everyday wear, while still providing comfort and protection to the wearer.

- Q: What is the dimensional stability of fiberglass fabric?

- Fiberglass fabric possesses remarkable dimensional stability, which is characterized by its capacity to sustain its shape and size without substantial stretching, shrinking, or warping in diverse circumstances. This outstanding dimensional stability is primarily attributed to the composition of fine glass fibers that are interlaced to create a taut and uniform structure. The glass fibers employed in fiberglass fabric demonstrate a high tensile strength, rendering them resistant to elongation or stretching. Consequently, the fabric remains true to its original dimensions even when subjected to mechanical stress or tension. Moreover, the glass fibers exhibit a low coefficient of thermal expansion, signifying minimal expansion or contraction in response to temperature fluctuations. This thermal stability greatly contributes to the fabric's ability to uphold its shape and size across a wide range of temperatures. Additionally, fiberglass fabric exhibits exceptional resistance to moisture absorption and chemical degradation. Unlike many other fabrics, fiberglass fabric repels water, thereby preventing significant absorption and subsequent dimensional alterations caused by moisture. Furthermore, the chemically inert nature of the glass fibers ensures resistance to most chemicals, safeguarding the fabric against chemical degradation that may compromise its dimensional stability. In conclusion, fiberglass fabric possesses excellent dimensional stability, making it a preferred choice in numerous industries such as aerospace, automotive, construction, and marine. Its capacity to maintain its shape, size, and structural integrity under diverse conditions renders it suitable for applications that demand consistent and dependable performance.

- Q: Can fiberglass fabric be used as a heat shield?

- Yes, fiberglass fabric can be used as a heat shield due to its high resistance to heat and flame. It is commonly utilized in various industries, including aerospace and automotive, to protect against heat and thermal radiation.

- Q: How is fiberglass fabric used in the environmental industry?

- Fiberglass fabric is commonly used in the environmental industry for various applications. It is often used as a reinforcement material in the construction of pollution control equipment, such as scrubbers and filters, due to its high strength and corrosion resistance. Additionally, fiberglass fabric is used to manufacture geotextiles, which are used for erosion control, soil stabilization, and landfill liners. Its durability and ability to withstand harsh environmental conditions make it a valuable material in the environmental industry.

- Q: How is fiberglass fabric used in the production of heat shields?

- Fiberglass fabric is commonly used in the production of heat shields due to its exceptional thermal insulation properties. Heat shields are designed to protect various components or structures from heat damage or excessive temperatures. Fiberglass fabric acts as a barrier between the heat source and the protected area, preventing the transfer of heat and reducing the risk of damage. The use of fiberglass fabric in heat shields is beneficial for several reasons. Firstly, fiberglass is a non-combustible material, meaning it does not burn or release harmful gases when exposed to high temperatures. This quality is crucial in heat shield applications, as it ensures the fabric remains intact and effective even under extreme heat conditions. Additionally, fiberglass fabric has excellent thermal insulation properties. It has a low thermal conductivity, meaning it does not conduct heat efficiently. This property allows the fabric to effectively trap and slow down the transfer of heat, preventing it from reaching the protected area. Fiberglass fabric is also highly flexible and lightweight, making it easier to incorporate into various heat shield designs. It can be easily molded or shaped to fit different applications, ensuring a proper and secure fit. Its lightweight nature also minimizes the overall weight of the heat shield, which is particularly advantageous in industries where weight reduction is crucial, such as aerospace. Furthermore, fiberglass fabric is resistant to many chemicals, moisture, and corrosion. This resistance makes it suitable for use in various environments and industries, including automotive, aerospace, industrial, and marine applications. In summary, fiberglass fabric is used in the production of heat shields due to its non-combustible nature, excellent thermal insulation properties, flexibility, lightweight design, and resistance to chemicals and moisture. Its incorporation into heat shield manufacturing ensures the effective protection of components or structures from heat damage, making it a highly valuable material in this application.

- Q: Glass fiber cloth can be made into handbags, requirements of high temperature 680 degrees or more

- In addition, a large number of additional filler (coating) material can be no longer, and the other you sew sewing bag, you must be able to withstand high temperature material yo, if not, then cloth is good, you can pack scattered. The best in the first point in the sewing material before you try again after high temperature before sewing.

- Q: Is fiberglass fabric flexible?

- Yes, fiberglass fabric is flexible. Fiberglass fabric is made from continuous glass fibers that are woven together to form a flexible and lightweight material. It can be easily bent, twisted, or molded into different shapes without breaking or losing its strength. This flexibility makes fiberglass fabric a versatile material that can be used in a wide range of applications, such as in the manufacturing of composite materials, insulation, and reinforcement for various products.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Above US$20 Million |

| Main Markets | Mid East;Western Europe;North America:South American |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 400,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | Average |

| Product Price Range | OEM Service Offered;Design Service Offered |

Send your message to us

Ewr400 Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords