Structural Composite Sandwich Panels - Polyurethane Foam Sandwich Panel / PU Foam Sandwich Wall Panels / Wall Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyurethane foam sandwich panel / PU foam sandwich wall panels / wall sandwich panel

Product Description

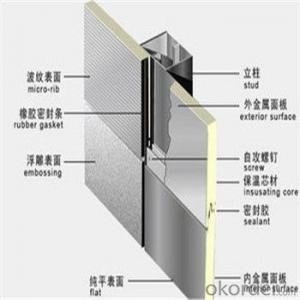

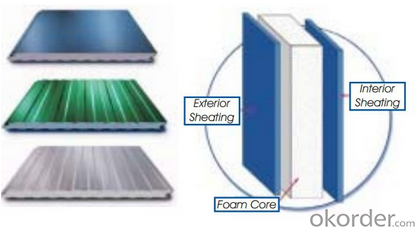

refrigeration panels for sale is adopting colour coating steel sheet as surface panel and polyurethane (PU) as core material.

This product with quick installation and good insulation which is

applied widely in: cold store, ceiling, temporary

house,dormitories,warehouse,workshop and etc.

Specifications:

1. Outer materails specification,

1) Two sides: painted steel sheet, stainless steel sheet and hot-galvanized steel sheet for customers' option

2) Thickness(mm): 0.3~0.8mm

3) Color: According to customer requirement

4) Width: 960mm

5) Length:According to customer requirement

2.Sandwich core: Polyurethane(PU)

Density: 38-40(kg/m3), 40-42(kg/m3), 42-45(kg/m3).

3.Fireproof:According to customer requirement, default is B2 grade

Introduction

PU Sandwich Panel

is fit for the projects which have serious require of keeping warm. Polyurethane core material is considered to the best material in keeping warm and thermal insulation.

The Polyurethane block material become steady after it froth, then combining with metal plates. The characteristics of this technique are: the polyurethane froth, after this chemical reaction is stable, we cut the polyurethane into pieces which with different thickness. The polyurethane sheet material has stable physical performance, it can combine with pre-painted hot galvanized steel sheets or stainless steel sheet, the surface is smooth and the whole performance is excellent.

2.Characteristics

1. sandwich wall panels

(the abbreviation of Polyurethane is PU sandwich panel) have characteristics of high load intensity, small waterabsorptive, and the stability in either low temperature or the high temperature is good, the service life is long, thermal insulation performance is outstanding and so on.

2. Good supporting, heat resistant, sound-insulated, sound absorption, light quality, non-toxic, odorless, green environmental protection.

3. Structural insulated panel system can cementation with the steel plates, the cements, the fiberboards, the bricks and many kinds of materials very strongly, in usual situation, it would not fall off and still strengthen its thermal insulation and waterproofing effects.

4. The unique produce foaming craft made the products have exquisite and even abscesses, the Thermal conductivity is low, the size stability is good, is very suitable for both of the low pressure and the high pressure construction.

5. Polyurethane foam plastics thermal stability is quite good, when the temperature is lower than 120°C, the volume and the intensity have no obvious change, its Thermal conductivity is small, when the density is 0.03kg/m3, the heat conductivity is only 63J(m.h.k)(15cal/m.h.k).

3. Specification

Effective width | 925mm,1000mm,1125mm |

Length | customized. less than 11.8 will be better for shipment |

Materials | PU & Color steel sheet |

Structure | Upper and lower layer: Color steel sheet |

Middle: polyurethane foam board | |

Thickness | Color steel sheet: 0.4-1.0mm |

Density | 38-45kg/m3 |

Color | customized |

Characters | Light in weight, heat insulation, water resistant, hidden screws and antirust,excellent quality and beautiful design. |

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

4.Product Technical Advantages

1. Tailor made by customers' requirement in terms of colours, thickness, density, and composite alteration.

2. A class fire-resistance( 650.C)fire-resistance period(120min)

3. Excellent thermal & sound insulation and energy saving performace

4. Hidden installation with no visible bolt fixing

5. Outstanding integrity and nice looking

6. Fast and easy installation

7. Excellent durability and strength

5. Anti oxidation

FAQ

The size of the panel can be changed?

Yes, according to the costumer's design.

Can you send samples?

Yes, you noly need to pay for freight charge.

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Single row of scaffolding, that is, the entire frame by a row of pole composition; due to its small range (generally only used in decorative construction), poor stability, erection height is small, has gradually withdrawn from the construction market

- Q: Reinforced concrete and metal sandwich board how much difference

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad.

- Q: I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad to give you a reference, hope useful

- Q: Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q: Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are commonly used in the construction of food kiosks due to their durability, insulation properties, and ease of installation. They provide a hygienic and easy-to-maintain surface, making them ideal for food-related businesses. Additionally, sandwich panels offer flexibility in design and can be customized to meet specific requirements, making them a popular choice for food kiosks.

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- The development of safe electricity technical measures and electrical fire prevention measures. ⒋ construction site temporary electricity safety technology files: ⑴ temporary electricity construction organization design and modify the construction organization design all the information. ⑵ technology to the end of information. ⑶ temporary electricity inspection inspection table. ⑷ grounding resistance measurement records. regular inspection (complex) look-up table (site monthly, the company once a quarter). ⑹ earthen worship of the cut of the irrigation pipe tax japonica maintenance work records. ⒌ installation, repair or removal of temporary electricity projects, must be completed by the electrician, electrical grade should be consistent with the degree of engineering and technical complexity to adapt. Second, the electrician: ⒈ electricians must go through professional and safety technical training, by the (city) labor department examination issued a certificate of operation, the prospective independent operation. ⒉ electrician should grasp the basic knowledge of electricity safety and all equipment performance. ⒊ before the job as required to wear personal protective equipment. slightly....

- Q: Can sandwich panels be used for noise barriers?

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are often made of two outer layers of rigid materials with a core of insulating material, which helps in reducing noise transmission. These panels can effectively absorb and block noise, making them suitable for constructing noise barriers in various settings such as highways, construction sites, or industrial areas.

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- Expandable polystyrene foam board (referred to as polystyrene board, the EPS board). Polystyrene Biscuit Powder Kuba Kawakun Fung Mo foam products are processed intermediate products, with less investment, fast turnover, low energy consumption, occupation of production personnel less, the production of high profit products. At the same time the number of devices less simple operation, strong production flexibility, product quality has a reliable guarantee, and thus the project construction risk is small. EPS board is made of polystyrene (EPS) beads made by foam molding. Polystyrene is invented in the 1950s, polystyrene foam products is a new type of advanced insulation, noise insulation materials. It is light in quality, non-toxic and tasteless, without any pollution. Use is very wide, mainly used for refrigerators, trains, ships, limousines, mobile homes, housing insulation insulation. Instrumentation, porcelain, glass products, home appliances and other packaging. In the construction industry it is an alternative to moisture-proof powder, perlite, asbestos and other insulation materials, is a very wide range of new products, so far there is no one product to replace the market prospects are very broad.

- Q: The stove is dedicated to the plastic used for plastic paper

- Fire level and density does not matter, with the lighter point can not fully explain the problem, b1 level to compound gb8624b1 level

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- the bottom of each pole should be set at the bottom or pad

Send your message to us

Structural Composite Sandwich Panels - Polyurethane Foam Sandwich Panel / PU Foam Sandwich Wall Panels / Wall Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords