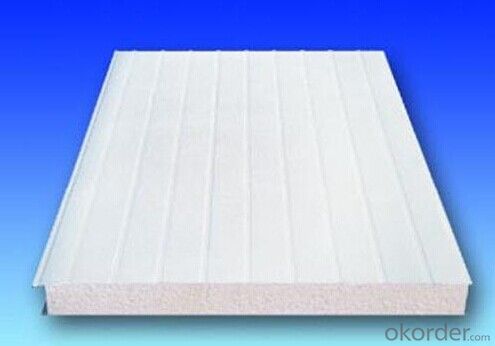

EPS Color Corrugated Galvanized Steel Sheet corrugated color steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

EPS Color Corrugated Galvanized Steel Sheet corrugated color steel sheet

Quick Details

| Standard: | Grade: | Place of Origin: | |||

| Brand Name: | Technique: | Surface Treatment: | |||

| Width: | Length: |

Packaging & Delivery

| Packaging Detail: | standard seaworthy packing |

| Delivery Detail: | 25 days |

Specifications

1.for civil building, car port, roofing, shelters, walk ways, fences & barns.

2. anti-rust.

3.good quality&service.

- Q: What is the standard size of a steel sheet?

- The specific application and industry play a significant role in determining the varying standard sizes of steel sheets. However, it is common to find steel sheets in standard sizes like 4 feet by 8 feet (1.2 meters by 2.4 meters) or 5 feet by 10 feet (1.5 meters by 3 meters). These dimensions are widely utilized in construction, manufacturing, and fabrication processes. It is worth mentioning that customized sizes can be obtained to cater to the specific needs of a project or customer.

- Q: Are steel sheets suitable for HVAC systems?

- Yes, steel sheets are suitable for HVAC systems. Steel sheets are commonly used in HVAC systems due to their durability, strength, and resistance to corrosion. They provide structural integrity to the system and can withstand high temperatures and pressure. Additionally, steel sheets are easy to fabricate and can be customized to fit specific HVAC system requirements. They are also cost-effective and have a long lifespan, making them a preferred choice for HVAC system components such as ductwork, ventilation systems, and air handling units.

- Q: Can steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding. Steel is a ferromagnetic material, meaning it can easily be magnetized and demagnetized. When placed between a magnetic source and an object, steel sheets can help redirect and absorb the magnetic field, thus providing effective shielding against magnetic interference.

- Q: Can steel sheets be used for outdoor sculptures or artwork?

- Absolutely, outdoor sculptures or artwork can certainly make use of steel sheets. Steel is known for its exceptional durability and strength, which makes it a perfect choice for outdoor settings where sculptures and artwork might face severe weather conditions. By bending, cutting, and welding steel sheets, artists can fashion them into various remarkable shapes and forms, enabling them to craft distinctive and elaborate designs. Moreover, steel can be painted or coated to shield it from rust and corrosion, ensuring that the artwork will endure for a long time. Numerous renowned outdoor sculptures worldwide are constructed from steel, highlighting its adaptability and appropriateness for outdoor applications.

- Q: Can steel sheets be perforated for ventilation purposes?

- Yes, steel sheets can be perforated for ventilation purposes. Perforations can be made in steel sheets to allow airflow and improve ventilation in various applications such as HVAC systems, architectural designs, industrial equipment, and more.

- Q: Are steel sheets vulnerable to UV radiation?

- Steel sheets are generally not vulnerable to UV radiation. This is because steel is a highly durable and resilient material that is resistant to many environmental factors, including UV radiation. Unlike some other materials, steel does not become weakened or degraded when exposed to prolonged sunlight or UV rays. In fact, many steel structures, such as buildings, bridges, and outdoor equipment, are designed to withstand outdoor conditions and can last for several decades without significant damage from UV radiation. However, it is important to note that certain types of steel, such as galvanized steel, may be more resistant to UV radiation due to additional protective coatings applied during the manufacturing process. Overall, steel sheets are a reliable choice for applications that require resistance to UV radiation.

- Q: What are the different sheet metal bending techniques for steel sheets?

- There are several sheet metal bending techniques commonly used for steel sheets. These techniques allow for the manipulation and shaping of steel sheets to achieve desired forms and angles. Some of the most common techniques include: 1. V-bending: This technique involves using a V-shaped punch and die set to create a sharp bend in the steel sheet. The material is placed between the punch and die, and force is applied to form the desired angle. V-bending is a versatile technique that can create various angles and shapes. 2. Air bending: In this technique, a punch is used to press the steel sheet into a V-shaped die, but without completely contacting the material. The bending is achieved by controlling the depth of penetration of the punch into the material. Air bending allows for greater flexibility in terms of angle adjustments and requires less force than other techniques. 3. Edge bending: As the name suggests, this technique involves bending the edge of the steel sheet. It is commonly used to create flanges or edges with specific angles. Edge bending is achieved by clamping the sheet between a punch and a die, and applying force to bend the material along the edge. 4. Bottom bending: This technique is used to create larger bends in steel sheets. It involves clamping the sheet between a punch and a V-shaped die, and then applying force to bend the material around the die. Bottom bending is suitable for creating U-shaped parts or boxes. 5. Roll bending: Also known as cylindrical bending, this technique is used to create cylindrical or curved shapes in steel sheets. The sheet is passed through a set of rolls, which gradually bend the material into the desired shape. Roll bending is commonly used in the production of pipes, tubes, and cylinders. 6. Coining: Coining is a precision bending technique that creates crisp, sharp bends. It involves pressing the steel sheet between a punch and a die, with the die featuring a sharp edge. The material is subjected to high pressure, resulting in a precise and defined bend. These are just a few of the many sheet metal bending techniques available for steel sheets. Each technique has its advantages and applications, and the choice of technique depends on factors such as the desired angle, the thickness of the sheet, and the complexity of the shape being formed.

- Q: Are the steel sheets resistant to impact or denting?

- Yes, steel sheets are highly resistant to impact and denting. Steel is known for its exceptional strength and durability, making it one of the most reliable materials for various applications. The inherent properties of steel, such as its high tensile strength and toughness, provide excellent resistance against impact and denting. Additionally, steel sheets can be further enhanced with special coatings or treatments to increase their resistance to impacts or dents, making them even more reliable in demanding environments. Overall, steel sheets are a preferred choice for applications where impact resistance and denting are significant concerns.

- Q: How are steel sheets coated for corrosion resistance?

- Steel sheets are typically coated for corrosion resistance through various methods such as hot-dip galvanizing, electroplating, or applying organic coatings like paints or powder coatings.

- Q: What is the typical composition of stainless steel sheets?

- The primary constituents of stainless steel sheets are iron, chromium, and nickel, which are responsible for its distinct properties. The proportions of these three elements can vary depending on the specific grade of stainless steel being utilized. On average, stainless steel sheets typically contain approximately 10-30% chromium and 8-20% nickel. Moreover, small quantities of other elements like carbon, manganese, and molybdenum may be present to further augment the strength, corrosion resistance, and other desired characteristics of the stainless steel. The composition of stainless steel sheets is meticulously balanced to attain the desired amalgamation of durability, strength, and resistance to corrosion, which makes it a highly favored choice across industries such as construction, automotive, and manufacturing.

Send your message to us

EPS Color Corrugated Galvanized Steel Sheet corrugated color steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords