EP NN CC PLIED CONVEYOR BELTS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality elevating rubber conveyor belts manufacturer

Product Description

Usage:

Suitable for factories, ports, docks, long distance, high strength, large volume of use.

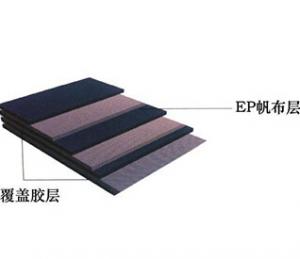

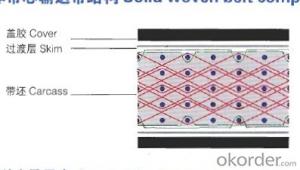

Varieties:

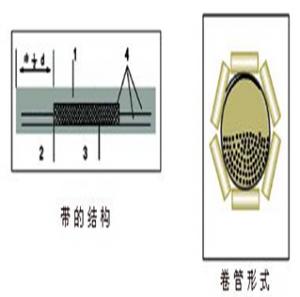

According to cover the performance can be divided into: ordinary type, smoldering, heat-resistant, wear-resistant, and resistant to. Cold type, acid type, oil type varieties.

Features:

Allow the use of high strength, high safely coefficient; elongation minima, tension travel a short distance; minimal tension elongation, travel a short distance; Steel wire rope and rubber combined with a solid, excellent dynamic performance; the belt body is soft, into a good grove, linear operation is good; excellent shock resistance; joint reliability, long service life.

Technical performance:

The performance in line with the GB/T5753-2008 standard; cover tape performance if user special requirements please contact us; impact resistance to tearing type can improve the impact resistance performance of 1-2 times, the tear resistance increase 0.5-1 times; cold-resistant lowest working temperature.

Techncial index list of conveyor belt:

Belt type | Fabric type | Single Fabric strength (N/mm) | Rubber cover thickness (mm) | Total thickness (mm) | Ply | Belt width (mm) | Belt length (m)/roll | |

Top rubber | Bottom rubber | |||||||

Cotton Canvas (CC) conveyor belt | CC-56 | 56 | 3.0-6.0 | 1.5-6.0 | 3-30 | 3-12 | 300-2800 | 200m |

Nylon (NN) conveyor belt | NN100 | 100 | ||||||

NN150 | 150 | |||||||

NN200 | 200 | |||||||

NN250 | 250 | |||||||

NN300 | 300 | |||||||

NN400 | 400 | |||||||

NN500 | 500 | |||||||

NN600 | 600 | |||||||

Polyester (EP) conveyor belt | EP100 | 100 | ||||||

EP150 | 150 | |||||||

EP200 | 200 | |||||||

EP250 | 250 | |||||||

EP300 | 300 | |||||||

EP350 | 350 | |||||||

EP400 | 400 | |||||||

EP500 | 500 | |||||||

EP600 | 600 | |||||||

Rubber performance levels of conveyor belt:

Level Code | Tensile strength Mpa≥ | Elongation at break % ≥ | Wear mm3 ≤ |

D | 18 | 400 | 90 |

H | 25 | 450 | 120 |

L | 20 | 400 | 150 |

P | 14 | 350 | 200 |

Note:D-strong wear working conditions;H-strong draw crack working condition;L-general working conditions;P-oil resistant,heat resistant,acid and alkali resistant,cold resistant and general flame resistant conveyor belt. | |||

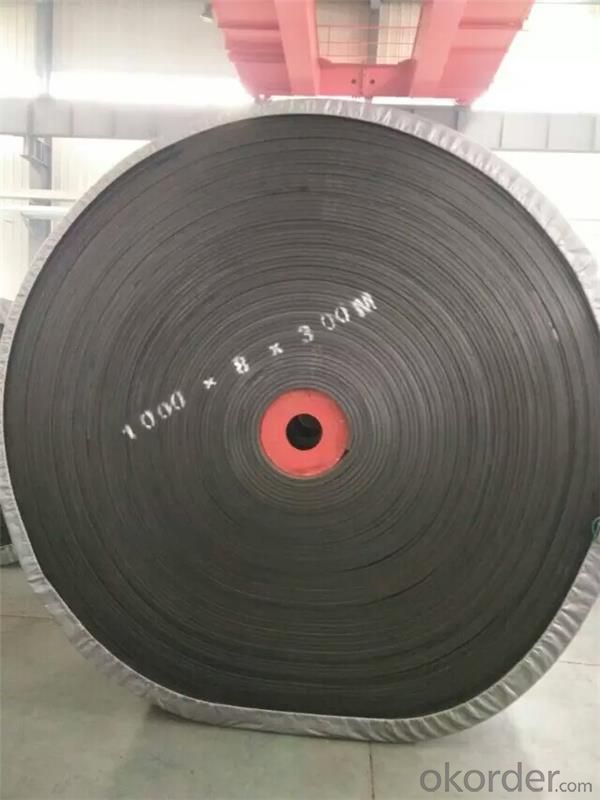

Product Pictures

- Q: Why are the engines almost all rubber belts?

- All kinds of driving methods have their own advantages and disadvantages.Sprocket, chain drive - transfer speed is limited.Gear transmission --- the transmission distance is limited and the noise is great.Belt drive - smooth transmission, quiet, easy to implement, low cost.

- Q: The difference between roller printing machine and rotary screen printing machine

- The 2 processes are continuous printing, faster than the speed of roller printing; in fine pattern is by fine carving to decide on it from the theoretical precision can reach 20 micron, also reflected in the actual production, but the rotary screen printing precision is by nickel mesh fineness (mesh) to decide on the current market maturity, below 155 mesh is more reasonable;

- Q: What kind of rubber belts are there for sporting goods?

- The elastic band is made of latex. Elastic band can effectively improve muscle strength, physical activity and flexibility.

- Q: How many layers of rubber band are glued together?

- Plain belt(with high strength nylon conveyor) products perform GB7984-2001 standards.Cover: the tensile strength of not less than 15Mpa, tensile elongation of not less than 350%, the wear is less than 200mm3, bonding strength between the layers is not less than the average value of the longitudinal 3.2N/mm layers of cloth, cover rubber and cloth layer is not less than 2.1 N/mmFull thickness longitudinal elongation of not less than 10%, the thickness of longitudinal reference force elongation is not greater than 1.5%

- Q: White rubber strap dirty, how to do?

- Then wash the back of the strap and clean the surface first. Next, clean the stains in the gap.Finally clean the strap with clean water. The procedures are completed, the rest of the things is to put the watchband in shady place to dry, do not pay attention to sun, will damage the quality of watchband.

- Q: JSP what does water swelling rubber belt mean?

- Water in the water will gradually swell in water, will eventually slow jam, the existence of pores in concrete and the interface contact more closely, resulting in high water pressure resistance, the formation of impermeable plastic colloid, this product has a high inflation rate, mobile added performance. In the construction joint seam, with balanced self-healing function strong, self sealing for settlement and the emergence of a new small gap, has completed the project, such as Water Leakage available water infiltration through the gaps, re plugging, low construction cost and simple construction process, excellent corrosion resistance.

- Q: Where can I buy 3mm thick rubber belts, black ones? Best to explain the price per square meter

- Of course, no more than 500 dollars a flat. Hope to help you. I think you have to make sure what the material is. First of all, I hope I can help you.

- Q: What do you call a machine that folds rubber bands into a stamp?

- These more complex machines are usually called machines. From the point of view of the structure and motion mechanism and machine, there is no difference between general machinery. Machinery, derived from the Greek Mechine and Latin Machina, originally referred to as "ingenious design", as a general mechanical concept, can be traced back to the ancient Rome period, mainly in order to distinguish between hand tools.

- Q: The rubber strap is a little tight, is it better or a little loose?

- The watch is no longer a ticking tool today. Your wrist is very thin, so I'll tell you what I know about trying to stretch on the elastic.

- Q: What's the difference between a rubber belt and a polyurethane belt?

- The strength and elasticity of rubber are betterPolyurethane is more flexible and less prone to deformation! The weight is comparatively lightThe plant's line is good with polyurethane!If it is a mine or coal or similar mineral, use rubber as a good point

Send your message to us

EP NN CC PLIED CONVEYOR BELTS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords