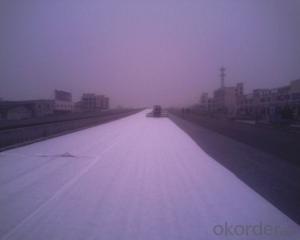

Non Woven Geotextile Membrane for Engineering in Road, Railway, Highway, and Tunnel Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Engineering Fiber for Road Railway Highway Tunnel

Made from polypropylene or polyester fiber by melting, spinning and anti-static treatment.

Specification of Engineering Fiber for Road Railway Highway Tunnel

I. Cement concrete fiber-PP net fiber

2. Cement mortar fiber-PP single fiber

3. Asphalt concrete fiber-PET fiber

Property of Engineering Fiber for Road Railway Highway Tunnel

I. High binding force with concrete

2. Prevent sedimentation and cracks

3. High tensile strength

4. High safety factor

Application of Engineering Fiber for Road Railway Highway Tunnel

I. Anti-crack in industrial and civil buildings

2. Basement and underground works, which require high waterproof and anti-crack performance

Seawalls dam and other salt water projects

3. AlI kinds of precast concrete products

4. Concrete in highway, bridge, tunnel, airport ground

5. Chemical plants which require high anti-alkaline and chemical resistance

Production Standard:

JT/T 525-2004

- Q: Geotextile how to sample

- It is best in the middle of a piece of cloth cut 1 square meters on the line

- Q: How do geotextiles contribute to climate change adaptation?

- Geotextiles contribute to climate change adaptation by providing effective solutions for erosion control, slope stabilization, and flood prevention. By reinforcing soil and preventing erosion, geotextiles help to protect vulnerable areas from the impacts of climate change, such as increased rainfall and extreme weather events. They also aid in water management by reducing sediment runoff and improving overall drainage systems. Additionally, geotextiles can be used in the construction of green infrastructure, such as permeable pavements and green roofs, which help mitigate urban heat island effects and improve stormwater management. Overall, geotextiles play a crucial role in enhancing resilience to climate change impacts and promoting sustainable development.

- Q: Can geotextiles be used for reinforcement of bridge abutments?

- Yes, geotextiles can be used for the reinforcement of bridge abutments. Geotextiles are commonly used in civil engineering projects for soil stabilization and erosion control. When applied to bridge abutments, geotextiles can help enhance the structural integrity and stability of the soil, preventing erosion and reducing the likelihood of settlement or shifting of the abutments. By acting as a barrier between the soil and the abutment, geotextiles distribute loads more evenly, increasing the overall strength and durability of the bridge structure.

- Q: Can geotextiles be used in foundations and retaining walls?

- Yes, geotextiles can be used in foundations and retaining walls. Geotextiles are commonly used in these applications as they provide reinforcement, separation, and filtration functions. They can help to prevent soil erosion, improve stability, and enhance the overall performance and durability of foundations and retaining walls.

- Q: How do geotextiles help with filtration in stormwater management systems?

- Geotextiles help with filtration in stormwater management systems by acting as a barrier that prevents soil erosion and retains sediment and pollutants. They allow water to flow through while trapping particles, thus improving water quality and reducing the chances of clogging in drainage systems.

- Q: Are geotextiles commonly used in coastal erosion control?

- Yes, geotextiles are commonly used in coastal erosion control. They are a popular choice due to their ability to stabilize soils and reduce erosion by acting as a barrier against wave action and water flow, while still allowing for water filtration. Geotextiles help to strengthen and protect coastlines, making them an effective solution in coastal erosion control strategies.

- Q: How do geotextiles help with soil stabilization in steep slopes?

- Geotextiles help with soil stabilization in steep slopes by providing a protective barrier that prevents erosion and helps to retain the soil in place. They act as a reinforcement layer, distributing the load across a wider area, reducing the likelihood of slope failure. Additionally, geotextiles promote water drainage, reducing the potential for saturation and increasing the slope's stability.

- Q: What are the advantages of using geotextiles in green roof systems?

- There are several advantages of using geotextiles in green roof systems. Firstly, geotextiles act as a barrier between the growing medium and the drainage layer, preventing soil erosion and ensuring proper water drainage. This helps to maintain the integrity and stability of the rooftop garden. Secondly, geotextiles can enhance water retention and reduce irrigation needs by improving moisture distribution throughout the green roof system. This promotes healthier plant growth and reduces the overall maintenance requirements. Additionally, geotextiles provide an added layer of protection against root penetration, preventing potential damage to the roof membrane. Overall, the use of geotextiles in green roof systems helps to optimize the performance, longevity, and sustainability of these systems.

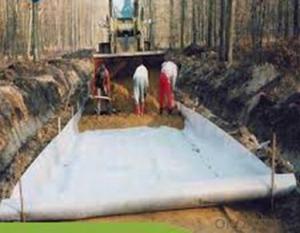

- Q: Can geotextiles be used in the construction of agricultural ponds?

- Yes, geotextiles can be used in the construction of agricultural ponds. Geotextiles are permeable fabrics that can be used to separate, filter, reinforce, or drain soils in various construction applications. In the case of agricultural ponds, geotextiles can be used to prevent soil erosion, stabilize slopes, and provide protection against punctures or tears in the pond lining. Additionally, geotextiles can help improve water quality by filtering out sediment and contaminants from runoff water entering the pond.

- Q: Ask geotextile factory in the use of geotextile aperture detector detection method which?

- Hello, geotextile detection method in GB / T and GB / T geotextile aperture in the introduction, you can look at these two standards. The first is geotextile pore size detection wet sieve method, the second is geotextile aperture detection dry sieve method. As the name suggests the first of these two methods is the participation of water, the other is basically the same, are placed in a single layer of geotextile standard small particles, through the vibration to detect the size of the leakage of particles to determine the geotextile pore size size. The difference is that the first standard in the need for continuous water on the particles, so the calculation method are also different. Specific detailed distinctions You can search these two criteria separately.

Send your message to us

Non Woven Geotextile Membrane for Engineering in Road, Railway, Highway, and Tunnel Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords