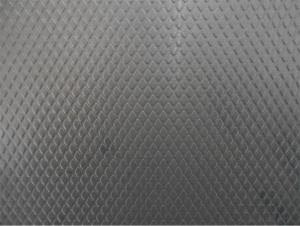

Bj's Embossed Aluminum Foil Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

- Q: Do 101 aluminum sheets have any specific insulation properties?

- 101 aluminum sheets do not possess any distinct insulation properties, as aluminum is an efficient conductor of both heat and electricity, failing to offer protection against temperature extremes. Nevertheless, these sheets can serve as reflective surfaces, effectively bouncing back heat or light. To achieve insulation, it is necessary to incorporate supplementary materials like foam or fiberglass in conjunction with the aluminum sheets.

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. They are lightweight, durable, and resistant to corrosion, making them an excellent choice for roofing materials. Additionally, aluminum sheets have good thermal properties, reflecting sunlight and helping to keep the building cool.

- Q: Are aluminum sheets suitable for transportation applications?

- Indeed, aluminum sheets prove to be appropriate for transportation purposes. With its lightweight and robust nature, aluminum emerges as an ideal material for diverse transportation needs. It finds widespread use in the aerospace sector, where it is employed in constructing aircraft structures. Similarly, in the automotive industry, aluminum is extensively utilized for fabricating vehicle bodies, frames, and components. By incorporating aluminum sheets into transportation applications, the overall weight of vehicles can be reduced, thereby enhancing fuel efficiency and increasing payload capacity. Moreover, aluminum's resistance to corrosion ensures its durability and longevity, even in harsh environments. All in all, the attributes of aluminum sheets render them a suitable and optimal choice for transportation applications.

- Q: Are 101 aluminum sheets resistant to corrosion?

- Yes, 101 aluminum sheets are resistant to corrosion. Aluminum is naturally resistant to corrosion due to its oxide layer that forms on its surface when exposed to oxygen. This oxide layer acts as a protective barrier against corrosion and prevents the metal from deteriorating. Additionally, the 101 aluminum alloy is specifically designed to have enhanced corrosion resistance properties, making it even more resistant to corrosion compared to other aluminum alloys. Therefore, 101 aluminum sheets are a reliable choice when corrosion resistance is a concern.

- Q: are there any hazards in aluminium?

- The metal, yes. But you can always face the risk of get cut if it has sharp edges.

- Q: there is a magnet for other type of nails except aluminum nails

- Not that I have heard of. The best way is manual hand pick up. If it is on concrete you might try making a pad out of a good stickey tape (turning the stickey part to the outside) that might speed up the process.

- Q: Are aluminum sheets suitable for construction applications?

- Yes, aluminum sheets are suitable for construction applications. Aluminum is a lightweight and durable material that offers several advantages in construction projects. It has high strength-to-weight ratio, making it easy to handle and transport while still providing excellent structural integrity. Aluminum sheets are corrosion-resistant, which makes them ideal for outdoor applications. They can withstand exposure to harsh weather conditions, such as rain, snow, and UV rays, without deteriorating or rusting. This resistance to corrosion ensures the longevity of the construction project. In addition, aluminum sheets are highly malleable and can be easily shaped and formed into various sizes and designs. This versatility allows architects and designers to create unique and aesthetically pleasing structures. Aluminum sheets can be used for roofing, siding, cladding, and façade systems, as well as in the construction of windows, doors, and curtain walls. Moreover, aluminum is a sustainable material, as it is 100% recyclable and requires significantly less energy to recycle compared to other metals. This makes aluminum sheets a more environmentally friendly choice for construction projects. In summary, aluminum sheets are suitable for construction applications due to their lightweight, durability, corrosion resistance, malleability, and sustainability. Their versatility and aesthetic appeal make them an excellent choice for a wide range of construction projects.

- Q: How do aluminum sheets perform in terms of chemical resistance?

- Good chemical resistance properties are typically found in aluminum sheets. However, their performance may vary depending on the specific chemical environment and conditions. Aluminum is known for its excellent resistance to corrosion from most acids, alkalis, and organic solvents. It creates a protective oxide layer on its surface, preventing further reaction with numerous chemicals. Nevertheless, aluminum can corrode in certain aggressive environments, such as strong acids like hydrochloric acid or sulfuric acid, as well as alkaline solutions with high pH levels. In these instances, the protective oxide layer can deteriorate, leading to the degradation of the aluminum surface. Furthermore, localized corrosion or pitting can occur on aluminum surfaces when exposed to certain chemicals like mercury and specific salts. Therefore, it is important to consider the specific chemicals and concentrations to which the aluminum sheets will be exposed when evaluating their chemical resistance. Various surface treatments, coatings, or alloys can be applied to enhance the chemical resistance of aluminum sheets. These modifications offer additional protection against specific chemicals or environmental conditions, further improving the overall chemical resistance properties of aluminum sheets. In conclusion, aluminum sheets generally possess good chemical resistance. However, their performance can be influenced by the specific chemical environment and conditions. It is advisable to assess the compatibility of aluminum with the intended chemicals and consider appropriate surface treatments or coatings if necessary.

- Q: What is the cost of an aluminum sheet?

- The price of an aluminum sheet can change due to various factors, including thickness, size, grade, and market conditions. Typically, aluminum sheets are priced based on square footage or weight. On average, the price can vary from $0.50 to $5 per square foot or $1 to $10 per pound. It is crucial to understand that these figures are approximate and subject to change based on factors such as supply and demand, location, and others. To obtain an accurate cost, it is advisable to reach out to local suppliers or explore online marketplaces for the latest pricing information.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

Send your message to us

Bj's Embossed Aluminum Foil Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords