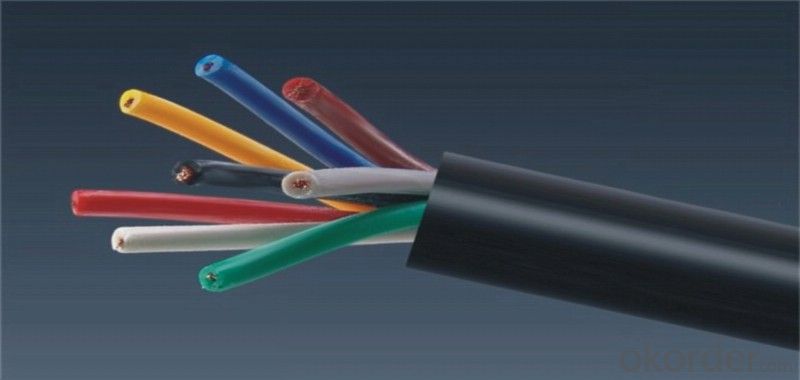

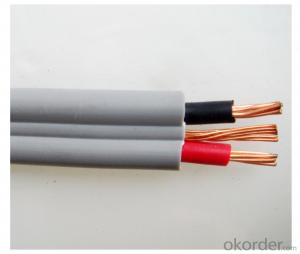

Electrical wiring and cable,single core copper conductor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applicant

1.) Household,indoor/outdoor,buliding wiring and associated devices ,to supply the power for lights fittings,switches,meters,plug point,air conditioners,refrigerators,water

pump,water heater,AC motor and etc.

2.) For decoration lights.

3.) Short span electricity transmission.

4.) For electrical appliance,electronic,instrument and telecom devices.

Specification

Description:

- Tinned or bare stranded 28-9AWG copper or tinned copper

- PVC insulated

- Temperature: 105 ° C; Voltage: 600V

- Use the standard thickness, easy stripping and cutting easy

- with anti-acid. oil resistance. moisture. mildew and other characteristics

1 | Model | AC10WE19 | ||

2 | Standard | GB/T 5023 IEC 60227 ICE60228 AS/NZS 3191 | ||

3 | Construction & Dimension | |||

Item | Specification | |||

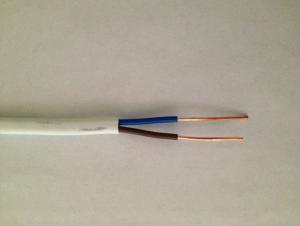

Conductor | Size | 3G 1.5mm² | ||

Material | Annealed Bare Copper | |||

Insulation | Material | PVC | ||

Min. Average Thickness | 0.7mm | |||

Min. Thickness at any point | 0.53mm | |||

Diameter | 3.1±0.10 | |||

Identification | Blue, Brown, Yellow/Green | |||

Core Assembly | Core Twist | 3--Core | ||

Filler | NA | |||

Assembly Pair | NA | |||

Taping | Mylar Foil | NA | ||

Shielded | A1 - Mylar Foil | NA | ||

Drain | Material | NA | ||

Construction | NA | |||

Jacket | Material | PVC | ||

Min Average Thickness | 0.90mm | |||

Min. Thickness at any point | 0.67mm | |||

Overall Diameter (Approx) | 8.5±0.20 | |||

Color | Any Color | |||

4 | Electrical & Physical Properties | |||

Item | Specification | |||

Rating Voltage | 300/500V | |||

Conductor Resistance | 13.3Ω/Km 20°c Max | |||

In case of dispute, Conductor resistance shall be the referee method | ||||

Insulation Resistance | 0.010MΩ/Km 70°c Min | |||

Dielectric Strength | AC 2.0KV/5 min No Break | |||

Insulation | Unaged | Tensile Strength | 10N/mm² | |

Elongation | 150% Min | |||

Aged | Tensile Strength | Min 10N Unaged±20%(85±2°cx240hrs) | ||

Elongation | Min 150% Unaged±20%(85±2°cx240hrs) | |||

Loss of mass Test | 2.0mg/cm² (max) | |||

Jacket | Unaged | Tensile Strength | 10N/mm² | |

Elongation | 150% Min | |||

Aged | Tensile Strength | Min 10N Unaged±20%(85±2°cx240hrs) | ||

Elongation | Min 150% Unaged±20%(85±2°cx240hrs) | |||

Loss of mass Test | 2.0mg/cm² (max) | |||

Deformation Test | 150mm, 70±2°c x 1hr≤50% | |||

Cold Bend Test | -15±2°c x 4hr No Crack | |||

Heat Shock Test | 150±2°c x 1hr No Crack | |||

Electric Properties | |

Item | Specification |

Specified voltage and temperature & standard | UL/CSA : 105℃, 600Vac, 750Vdc, ROHS / RECH |

Spark Test | The insulation must be withstand 5KV high-tension current |

Insulation Potengial Strength | 2000V/Min(for water's environment |

Minimum Insulation Resistance | 20℃, DC500V 15MΩ-KM Above |

Physical Properties | |||

Based on standard of flammability material testing | According for UL Subj.758 spec/According for CSA spec | ||

Before of aging test | Insulation tensile strength test kgf/mm2 | 1500 psi above | |

Insulation elongation test rate % | 100% above | ||

After of aging test | Insulation tensile remnant rate % | This amount must be above 70% after heat ageing (136℃,168hrs) | |

Insulation elogates remnant rate % | This amount must be above 65% after heat aging (136℃,168hrs) | ||

Heating Distortion Test | The insulation face must be no cracked, high temperature at 120℃ for 1 hour | ||

Thermo Shock Test | The insulation face must be no cracked, high temperature at 120℃ for 1 hour and bent, to withstand 1,000V for 1 Min | ||

Cold Bending Test | The insulation face must be no cracked, cooled at -40℃ for 3 hour and bent to withstand 1000V for 1 Min | ||

Oil Resistance | Immersed in oil at 80℃ for 4 hrs and bent to withstand 1000V for 1 | ||

- Q: 4 square of single-core wire, the diameter is how much? Refers to the inside of the copper core diameter? Or even the skin together?

- Induction of electricity, the line in the immediate situation, and quite long will produce

- Q: I have an old craftsman Powr Panl (yes spelled that way) and it has an extension cord on it that has 10 individual wires on the inside. There are 5 dull white ones, and then five that are: bright white, red, black, green, and brown. Any ideas? This is the original cord, and was hooked up in 1950 at one point. Any ideas?

- Standard colors for power cords these days are white (for neutral/return), black (for 'hot' - think bad guys in black hats, it's the wire that will zap you if holding onto the kitchen faucet when live and you touch it), and green (for ground). Note that the white wire is the return path that carries current while the green is usually connected to the case or chassis and should trip the circuit breaker if it begins to carry current. A guess? The name Powr Panl suggests that this is a power distribution panel with multiple outlets. It's possible the color coding was used to help track connections to ganged panels. Just a guess though. With perhaps more detail, a better informed guess could be made. What does the panel look like? How large are the wires? To what do they connect? Feel free to email for follow-up.

- Q: Hello We have been running a room heater and humidifier from a bedroom wall electrical outlet for the last 4-5 months with no issue.2 days ago we noticed a burning/melting plastic smell when we ran the appliances for 10-15 mins. I checked the wall outlet after removing its cover and visually looks OK i.e. no blackening. I have not removed the actual sockets. Also, the appliances themselves seem to be OK i.e. no smell from them.Could the issue be in the wiring inside a wall? How to determine this? The smell seems to starts when we use this particular outlet only.If problem is not in outlet, then will the wall need to be broken into to determine the source of the problem? Is there a more sophisticated solution?What could have caused this sudden issue? A rodent? Water leakage thru the siding? Other ideas?Note that the circuit breakers have not tripped during this time to indicate overload etc.Thanks in advance for your opinions.Homeowner_ne

- Sounds like the outlet has a loose connection, causing arcing and overheating of the insulation on the wire. Check out the outlet or hire someone to do so before you use it again. If it is getting hot enough to make the insulation burn you have a potential fire hazard. Bert

- Q: Do I need to put the foam in the studs where the electrical wiring goes through? This is for Fire codes in MN

- Use Fire caulk, nor foam. In New Jersey it is illegal to use foam because it creates toxic fumes when it burns, and yes it burns.

- Q: (No I didn't do it.) I have a used vacuum and it has some damage to it's electrical cord by someone running over it several times. Some of the electrical wires are exposed but there is no damage to the wires, so it seems. What do you recommend other than replacing the vacuum? Thanks

- yes, if the conductor is not exposed. Make sure to put a minimum of 2 layers of tape, more is safer.

- Q: 1 phase partial HP motor does the cap get wired to the line side of the circuit? I got a junk motor and table saw that was wired with a 2 conductor cable and the line/neutral was a maybe. When I replaced the cable and cleaned the start switch it now trips the breaker. I then reversed the line/ n connections and it hums but does not start. I cleaned the dust and have read to ground for a clean insulation. After 50 some years in the electrical industry, I now need to wire some motors internally rather than send 'em to the shop for a rewind. Thanks guys.

- On all motors the Capacitor gos between the L1 and centrifugal (cut out)switch (which then gos to the start winding).In ac L1 and L2 are reversible toward the power source

- Q: A friend of mine had his kitchen remodeled and the wiring for the cabinets is visible in the back of the cabinets. It is also stapled to the side and the back of the cabinet and runs to the bottom corner to the recessed lights. I told him electrical wiring should not be stapled and not visible. I have never opened a cabinet with exposed wiring. Not only that but the molding is not secured to the external cabinet. The doors on the front also have a 1/4 or so gap when closed. I said the doors need to be flush, almost touching. Not a gap like Dave Lettermans teeth.

- The wires should be in the wall, but looks like someone took a shortcut. The only wires that should be visible in a cabinet are under the sink with a power lead plug running from the food disposal and dishwasher to a under-the-sink covered wall outlet. faculty.sbc.edu/simpson/remod

- Q: I plugged in a computer to one of my outlets. I felt current passing through my band as I touched the case and held the monitor Connection and got a big spark when I tried to connect the monitor. This only happens on that outlet.

- The diagram you show is for a split receptacle where one outlet is hot at all times while the other is controlled by a switch. This is why the tab on the right has been removed. The tab one the left is retained in order for both outlets to share the neutral wire. Since you say that the red wire is not present in your case this does not apply. If you only have two conductors and a ground coming in to the electrical box, this is the end of a circuit. The bare ground wire should be attached to the ground terminal. The white neutral wire should be attached to the terminal with the silver terminal and the hot black wire should be attached to the darker or brass colored terminal. Once this is done the receptacle should function properly. If it does not, replace it.

- Q: A 4400 watt motor is located 930 feet away from the 240v source. The motor's minimum voltage is 220 volts. What size of wire is required to maintain at least 220v at the pump? How much power is lost with this size wire?Please help! Thanks!

- use okorder

- Q: What is the role of the two-color wire and monochrome wire?

- 1. Birds are just standing on a wire can not form a loop so there is no electric shock. 2. Birds feet from the distance even in the high voltage line will not form a step voltage.

Send your message to us

Electrical wiring and cable,single core copper conductor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords