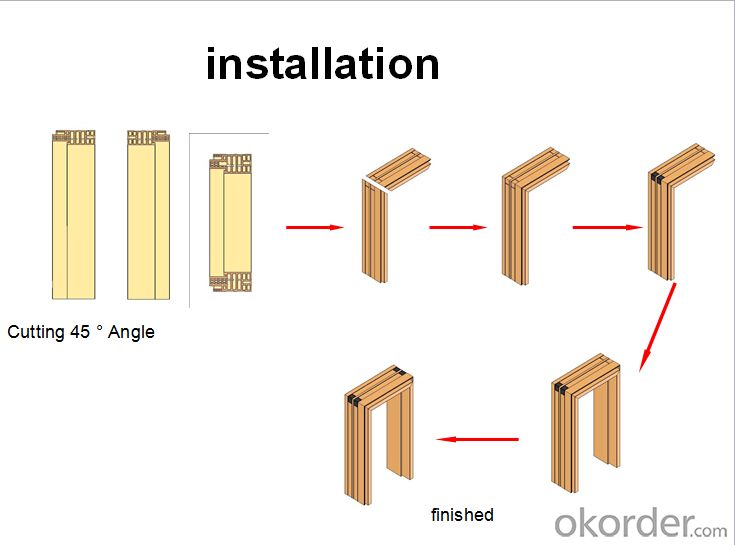

Easy to Install, Low Labor Cost WPC Door Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is Low Labor Cost WPC Door Frame?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> Why choose Low Labor Cost WPC Door Frame?

Natural colour

Resistance to water, rot and crack

Guaranteed to last

Low maintenance

Beautiful and broad range of finish

3> What are the main kinds of Low Labor Cost WPC Door Frame currently?

Door frame

Wall panel

Skirting

Wardrobe door panel

Product Description

4> Specification of Low Labor Cost WPC Door Frame?

Characteristics | WPC | Wood |

Moisture Resistance | Waterproof | Water absorptive |

Rot Resistance | Antisepsis | Rot except special treating |

Split Resistance | No Cracked | Cracked by weathering effect |

Distortion Resistance | Almost no Contraction/expansion | Distorting effected by chang of moisture and temperature |

UV Resistance | High Grade UV Resistance | Easily effected by UV |

Fading Resistance | Almost no | Easy to fade |

Outdoor adaptability | Great | Only few of treatedowood adaptive |

No need painting | No need | Need paint periodically |

Durable/longevity | > 8-15 years | < 3 years< span=""> |

Various Configuration | Extruded via various mould | simplex |

Environment Effect | Recyclable 100% | Consume woods |

Company Information

5> About CNBM and It’s Low Labor Cost WPC Door Frame

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

Preferential payment terms

good and reasonable price

quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

professional team for CRM order processing & QA & logistics

global logistic database, originated from Dubai

Packaging & Shipping

6> How to buy and concerned terms

MOQ – 800m per item

Lead time—2 weeks

Departure port—Shanghai

Package-- PE film, carton box or 2pcs.bundle, treated pallet

7> Certificates and Quality guarantee

Certificates – CE&ISO 9001 complied

Warranty—10 years

Quality guarantee—test report for each order under the strict management system

- Q: Lead alloy doors and windows of the joints how waterproof

- First, the aluminum alloy windows and doors water seepage analysis 1. doors and windows of their own water seepage 1.1 their own closed lax; 1.2 own drainage system drainage is poor; 2. doors and windows installed improperly generated cracks, resulting in seepage 2.1 windows and doors frame deformation caused by the wall with the The gap between the windows and doors and the wall between the wall of the filler is not uniform, and the resulting gap;

- Q: What are the installation of the box method?

- The contractor shall, in accordance with the size of the aluminum window, first process a sub-frame (size 4cmx2cmx2mm) of 5 to 8mm thick inside the aluminum window, and the contractor shall be responsible for installing the sub-frame. The contractor should be based on the size of doors and windows, the first processing of an inner side than the aluminum window 5 to 8mm galvanized steel pipe sub-box [size 4cmx2cmx2mm], and by the contractor is responsible for the installation of sub-box. The process is: sub-box installation fixed → waterproof mortar packing → indoor to the sub-frame with fine stone concrete pouring and plastering side → outdoor brush waterproof layer → outdoor cement mortar + inorganic insulation + brick

- Q: How to construct the outdoor rock wool insulation board

- Garbage product waste system, early stop production

- Q: Paving mosaic construction process

- With the high-end mosaic paving, paste construction is simple and convenient, it is characterized by not corrosion the bottom and prevent oxidation black, strong sticky, and suitable for flooding environment.

- Q: Broken bridge aluminum screens how to go up

- The first step: the yarn box, air slot, bottom assembled, and then use six screws to twist it to make it a square box. The second step: the screen on the installation site, pay attention to the left and right air duct and the door window frame to the left and right symmetry, bottom position from the door frame frame to be about 5cm lower, put the left and right with the clip, Doors and windows so that they can not move. The third step: with electric drill with 3.2mm drill bit in the door window frame inside the puncture. Step 4: According to the need in the left and right air trough and below the bottom of the corresponding place marked with 6 to 14 eyes, and then screw the screw is installed. Installation Notes: 1, the yarn box to be vertical fixed, broken bridge aluminum doors and windows at both ends to occupy the upper and lower border prevail. 2, up and down the slide with the location of the parallel box fixed, to avoid skid inside and outside skew. 3, the base position to close the pull beam, placed in the sliding window swoop to close and then draw lines and fixed, so as not to fixed position too far or too far. 4, if the parts of the fixed nail is too long, will prevent the normal sliding sliding window slick, broken bridge aluminum doors and windows can be self-nail with a shears cut short can be.

- Q: Can ordinary sliding windows be installed with stealth screens?

- There is no problem with the technology, can be installed; the problem is to be installed in the window outside, that is, the top of a window outside the top, after the end of the window can not be moved, the sealing effect is no problem, but the biggest drawback is paint When the glass is not convenient, the inside of a window can not be completely applied to; you can choose "Lu Cheng" brand can be disassembled cleaning, or with the flat; 1 will be the yarn box, air slot, bottom assembled, and then with six Screw the screw to twist it into a square box. 2 will be on the installation of the screen window, pay attention to the left and right wind groove and the door window frame to the left and right symmetry, bottom position from the door frame 3 border to be about 5cm lower, put the left and right with the clip to live, so that can not move. 4 with drill with 3.2mm drill bit in the door window frame inside the puncture. 5 according to the need in the left and right air groove and below the bottom of the corresponding place marked with 6 to 14 eyes, and then screw the screw is installed. Note that the yarn box to be vertical fixed, both ends of the upper and lower border to prevail. The upper and lower slide rails are fixed in parallel with the position of the yarn box to avoid skew inside and outside the slide. The base position should be close to the pull beam, placed in the sliding window to close and then draw lines and fixed, so as not to fixed position too far or too far. If the parts of the fixed nail is too long, will prevent the normal sliding sliding window slick, can be self-pin nails can be cut with a claw cut.

- Q: Do the doors and windows installed in the hole before the installation of metal sub-frame, and then install the main frame, the main frame and sub-frame between the cracks to how to deal with? More

- The use of foam caulking agent is also called styrofoam, plus cleaning agent.

- Q: My side of the wall paint 5 years of the top there are cracking the place, I want to shovel them to re-brush latex paint, but the floor of the floor I do not want to move, afraid of the construction of the workers when the workers hit bad, how can I do? Question added: the home there are a lot of furniture, it can not move, the bedroom bed closet, the living room of some have, how can I protect up ah. More

- Buy some shock film (or use the largest trash bag), shop on the floor, the corner of the place with the US pattern paper sticky on the line, the earthquake can be sold in the sale of wood flooring place, foot line and doors and windows The edge of the box can be used to cover the wall of the United States and the United States, the United States and paper is easy to peel off, do not damage the surface of the object, it will not leave marks. There are furniture, then you can use the old sheets or large plastic sheet cover up, compared to the old bed sheets easier to use, plastic more easily due to static and soil.

- Q: Engineering materials inside the windows and doors hidden when to do? Is done in the main construction, or do the decoration when the doors and windows to do the decoration?

- In the installation of doors and windows to do.

- Q: How to deal with waterproof coatings on aluminum windows

- Is the decoration finished splashing above? Can be washed with water. It is best not to use a sharp knife, do not use corrosive chemical products wash.

Send your message to us

Easy to Install, Low Labor Cost WPC Door Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords