Earthquake Resistant Corrugated Deformed Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 190 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Earthquake Resistant Corrugated Deformed Steel Bar

Description of Earthquake Resistant Corrugated Deformed Steel Bar

1, Diameter: 5.5mm-10mm Earthquake Resistant Corrugated Deformed Steel Bar

10m- 40mm Earthquake Resistant Corrugated Deformed Steel Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Earthquake Resistant Corrugated Deformed Steel Bar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

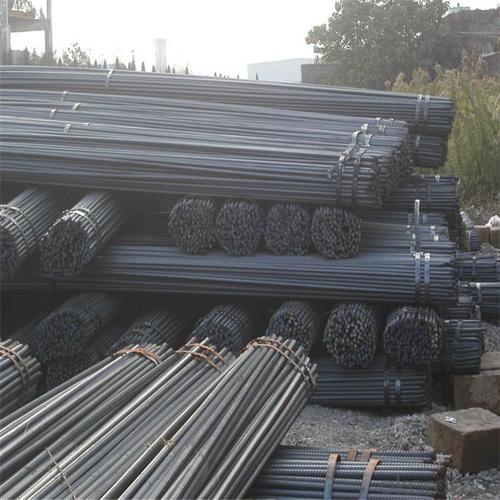

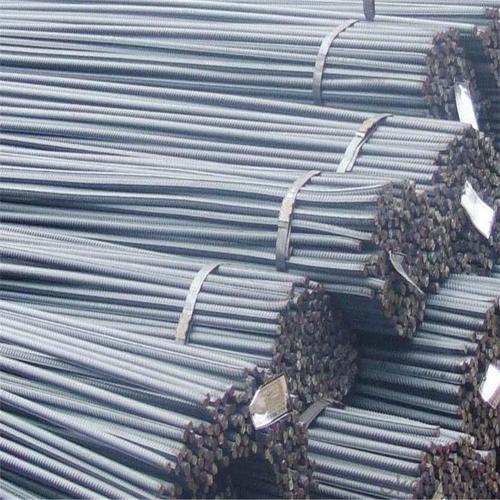

Products Show of Earthquake Resistant Corrugated Deformed Steel Bar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the properties of nickel-based alloys?

- Nickel-based alloys possess several key properties including high corrosion resistance, excellent heat resistance, good mechanical strength, and a combination of high toughness and durability. They also exhibit good electrical and thermal conductivity, making them suitable for various applications in industries such as aerospace, chemical processing, and power generation. Additionally, nickel-based alloys have the ability to maintain their properties at elevated temperatures, making them ideal for use in extreme environments.

- Q: How does special steel perform in terms of corrosion resistance in acidic environments?

- Special steel, such as stainless steel, exhibits excellent corrosion resistance in acidic environments due to its high chromium content. The chromium forms a protective oxide layer on the surface of the steel, preventing the corrosive attack of acids. This makes special steel a reliable choice for applications where exposure to acidic environments is a concern.

- Q: How does special steel contribute to the automotive racing aftermarket industry?

- Special steel plays a crucial role in the automotive racing aftermarket industry by providing the necessary strength, durability, and performance required for high-performance racing vehicles. In this industry, where speed, precision, and safety are paramount, special steel offers unique properties that enable engineers and manufacturers to push the limits of performance. One key way that special steel contributes to the automotive racing aftermarket industry is through its ability to withstand extreme conditions. Racing vehicles are subjected to intense heat, pressure, and vibrations during high-speed races, which can put immense stress on various components. Special steel, with its exceptional heat resistance and high tensile strength, ensures that critical parts like engine components, transmission gears, and suspension systems can withstand these harsh conditions without compromising performance or safety. Furthermore, special steel is known for its lightweight properties, making it an ideal material for racing vehicle components. Weight reduction is a crucial aspect of racing as it directly impacts acceleration, handling, and overall performance. By using special steel, manufacturers can create lighter yet stronger components, allowing racing teams to achieve higher speeds, better maneuverability, and improved fuel efficiency. Special steel also contributes to the automotive racing aftermarket industry by offering excellent machinability and weldability. This allows for precise customization and modification of components, catering to the specific needs and preferences of racing teams. Whether it is creating custom engine blocks, exhaust systems, or chassis reinforcements, special steel provides the flexibility required to optimize performance and gain a competitive edge. Moreover, the use of special steel in the automotive racing aftermarket industry promotes innovation and technological advancements. Steel manufacturers continually develop new alloys and compositions that enhance the performance capabilities of racing vehicles. These advancements can include improved corrosion resistance, better fatigue strength, and enhanced material properties, all of which contribute to the overall performance and longevity of racing vehicle components. In summary, special steel is a vital contributor to the automotive racing aftermarket industry. Its unique combination of strength, durability, lightweight properties, and machinability enables racing teams to design and manufacture high-performance vehicles that can withstand extreme conditions. By leveraging the advantages of special steel, the industry can continue to push the boundaries of automotive racing, delivering faster, safer, and more efficient racing machines.

- Q: How does special steel contribute to the construction sector?

- Special steel contributes to the construction sector by providing enhanced strength, durability, and corrosion resistance to various structural components. Its unique properties enable the construction of high-rise buildings, bridges, and infrastructure projects that can withstand extreme conditions and last for decades. Additionally, special steel offers flexibility in design, allowing for innovative and efficient construction techniques.

- Q: What are the future trends in special steel manufacturing?

- The future trends in special steel manufacturing are likely to focus on advancements in technology, sustainability, and the development of new alloys. Firstly, technology will play a significant role in shaping the future of special steel manufacturing. Automation and robotics are expected to be increasingly integrated into the production process, leading to improved efficiency, precision, and reduced labor costs. This will also allow for better quality control and the ability to produce more complex and customized steel products. Secondly, sustainability will be a key focus in special steel manufacturing. As the world becomes more environmentally conscious, companies are seeking ways to reduce their carbon footprint. This includes employing cleaner production methods, such as using renewable energy sources and implementing recycling programs to minimize waste. Additionally, there will likely be a shift towards developing greener alloys with reduced environmental impact. Furthermore, the development of new alloys will be crucial in meeting the evolving needs of various industries. With advancements in material science, special steel manufacturers will be able to create alloys with enhanced properties, such as increased strength, durability, corrosion resistance, and heat resistance. These new alloys will cater to the growing demand for high-performance materials in sectors like aerospace, automotive, energy, and construction. Moreover, the future of special steel manufacturing is also likely to be influenced by the increasing demand for lightweight materials. As industries strive to improve fuel efficiency and reduce emissions, there will be a need for special steel alloys that offer high strength-to-weight ratios. This will drive research and development efforts towards creating lighter yet stronger steel products. In conclusion, the future trends in special steel manufacturing will revolve around technological advancements, sustainability, and the development of new alloys. These trends will shape the industry, bringing about increased automation, cleaner production methods, and the creation of innovative alloys to meet the changing needs of various sectors.

- Q: How does surface treatment affect the performance of special steel?

- The performance of special steel is greatly enhanced by surface treatment, which serves the essential purpose of altering the steel's surface properties to meet specific requirements and improve its performance in various applications. One notable effect of surface treatment on special steel is the increased resistance to corrosion. Coatings or treatments such as galvanization, electroplating, or passivation are applied to make the steel's surface more resilient against the damaging effects of moisture, chemicals, and other corrosive agents. This is particularly crucial in industries like construction, automotive, or marine, where steel is subjected to harsh environments. Surface treatment also has an impact on the wear resistance of special steel. Through processes like carburizing, nitriding, or boriding, a thin layer of hard and wear-resistant material is formed on the surface of the steel. This significantly enhances its ability to withstand friction, abrasion, and mechanical stress, making it suitable for applications involving heavy machinery, cutting tools, or bearings. Moreover, surface treatment can enhance the aesthetic appeal of special steel. Techniques such as polishing, grinding, or coating can be employed to improve the appearance of the steel, making it more visually pleasing for architectural or decorative purposes. Another crucial aspect affected by surface treatment is the adhesion properties of the steel. By modifying the surface through processes like shot peening or surface etching, the steel becomes more receptive to adhesives, paints, or coatings. This improves the bond strength between the steel and other materials, making it suitable for applications where adhesion is critical, such as in the aerospace or electronics industries. To summarize, surface treatment has a significant impact on the performance of special steel. It enhances corrosion resistance, wear resistance, adhesion properties, and aesthetic appeal. Manufacturers can maximize the steel's performance and extend its lifespan by selecting the appropriate surface treatment techniques to tailor its surface properties to meet specific application requirements.

- Q: Can special steel be used in the manufacturing of firearms?

- Yes, special steel can definitely be used in the manufacturing of firearms. In fact, special steel is often preferred for this purpose due to its unique properties that make it suitable for withstanding high temperatures, pressures, and stress. Firearms require materials that are strong, durable, and able to handle the intense forces generated during firing. Special steel alloys, such as stainless steel or heat-treated steel, offer these desired characteristics and are commonly used in the production of firearm barrels, receivers, and other critical components. The use of special steel in firearms manufacturing ensures that the weapons are reliable, safe, and able to perform consistently under various conditions.

- Q: What are the advantages of using special steel in industrial applications?

- Special steel offers several advantages in industrial applications: 1. Durability: Special steel is known for its exceptional strength and hardness, making it highly resistant to wear and tear. This durability allows it to withstand extreme conditions, such as high temperatures or corrosive environments. 2. Versatility: Special steel can be tailored to meet specific requirements, allowing for the production of a wide range of products. It can be alloyed with other metals or elements to enhance its properties, making it suitable for various industrial applications. 3. High performance: Special steel exhibits superior mechanical properties, including high tensile strength, toughness, and impact resistance. These characteristics make it ideal for applications that demand reliability and performance, such as machinery, tools, and equipment. 4. Resistance to corrosion: Special steel can be manufactured with corrosion-resistant properties, offering protection against rust and deterioration over time. This makes it suitable for applications exposed to moisture, chemicals, or harsh weather conditions. 5. Cost-effectiveness: Although special steel may have a higher initial cost compared to other materials, its long lifespan and low maintenance requirements make it cost-effective in the long run. Its durability and resistance to wear reduce the need for frequent replacements or repairs, resulting in reduced downtime and overall operational costs. In summary, the advantages of using special steel in industrial applications include durability, versatility, high performance, resistance to corrosion, and cost-effectiveness.

- Q: What are the different methods of surface shot blasting for special steel?

- Special steel can be subjected to various surface shot blasting techniques. Among the most commonly employed methods are: 1. Wheel blasting: Utilizing a rapidly spinning wheel embedded with abrasive particles, this technique eliminates impurities and imperfections from the surface of the special steel. 2. Air blasting: By propelling abrasive particles onto the special steel surface using compressed air, this method achieves a thorough cleaning and prepares the surface for subsequent treatment or coating. 3. Wet blasting: This approach involves blending abrasive particles with water and spraying the resulting mixture onto the special steel surface. The inclusion of water helps manage dust and heat generated during the blasting process, rendering it suitable for delicate or sensitive steel surfaces. 4. Vacuum blasting: By incorporating a vacuum system alongside abrasive particles, this technique effectively eliminates both particles and contaminants from the special steel surface. It proves particularly valuable for removing paint or coatings. 5. Shot peening: Employed as a specialized variant of shot blasting, shot peening enhances the strength and fatigue resistance of special steel. It entails bombarding the surface with small spherical particles, generating compressive stresses that bolster the steel's durability. Each of these methods offers distinct advantages and is suitable for different types of special steel and surface conditions. The selection of the appropriate technique hinges upon factors like desired surface finish, contamination levels, and specific steel application requirements.

- Q: How does special steel contribute to reducing product rejection rates in quality control?

- Special steel contributes to reducing product rejection rates in quality control by providing superior strength, durability, and resistance to wear and tear. These properties enable the production of high-quality components and eliminate common defects such as distortion, cracking, or premature failure. Additionally, special steel's precise composition and manufacturing processes ensure consistency and accuracy in the final products, reducing the likelihood of manufacturing errors and subsequent rejection during quality control inspections.

Send your message to us

Earthquake Resistant Corrugated Deformed Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 190 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords