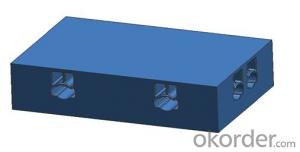

EANTE Exterior angle Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Haiyuan New Material possesses china’s first fully automatic long fiber reinforced thermoplastic composite mould pressing production line with independent intellectual property, referred to as LFT-D line.

Why we developed EANTE formwork?

Superiority:

General worker can assemble and remove easily, save more labor cost.

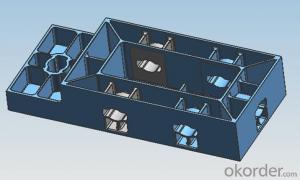

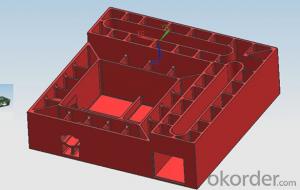

The reinforcing ribs of EANTE formwork can be used to instead of the steel tube and wood.

Preassemble the EANTE formwork in the factory and fix it in the construction location.

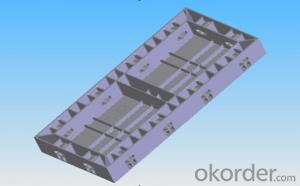

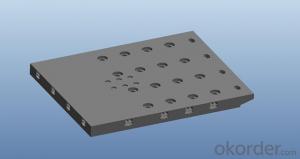

The size accuracy of the composite formwork is better than that of the steel formwork and the wooden formwork. The concrete surface cast by EANTE Formwork is quite smooth, without any flaw, and no release agent is applied to assist the formwork removing.

We developed our own software with the characteristics as follow:

a. Computation time: it depends on the complexity of the architecture drawing;

b. Construction drawing: it is shifted from assembling drawing easily;

c. Material list: the assembling designing software would generate a list of formwork elements and auxiliary products.

Enviromental: EANTE Formwork is made from composite material, which is low-carbon, recyclable and environment-friendly.

Saftness: The labor, large equipment, electric saws and iron nails are used much less on the building site, which leads to simplified on-site management and the safer construction.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Pvc plate deformation are: physical deformation and chemical deformation.A physical deformation, the cause:???? High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems???? Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the rootTwo chemical deformation: mainly the molecular structure of raw materials change.

- Q: Who used it, how not universal.

- 4. The product pouring concrete surface smooth, bright as a mirror, to meet the requirements of decorative and decorative water, eliminating the need for secondary plastering process. 5. Turnover times more than 50 times, the template each time the amortization cost is less than 3 yuan, steel frame plastic template turnover times more than 300 6. The material is non-toxic, harmless, pollution-free, 100% recovery, green products The 7. The product acid, alkali, anti-corrosion performance. Product use temperature of -80 ℃ ~ 100 ℃, good weather resistance.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Wood-plastic building templates in the construction works more useful, more affordable, more convenient.

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- Plastic mold is better, light weight, high impact strength, easy assembly, high turnover rate, smooth surface, no moisture, no mildew, Naisuan Jian, no cracking, large plate, less joints, can be saw, can Nail, can be processed into any length and so on

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- To be honest, not very good. The Temporary use can be

- Q: Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

- Q: Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- With pliers slowly pull, or spray gun spray.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- In summary, what template to use depends on what your structure needs.

- Q: The price of raw materials can say better, is the PVC material.

- General templates are fixed specifications, such as 1.22 * 2.44,980 * 2200 so it is generally in accordance with each template to price

Send your message to us

EANTE Exterior angle Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords