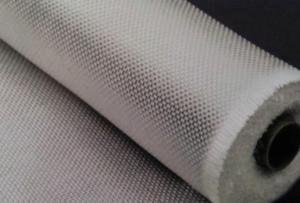

Fiberglass Mat Tissue - e-glass fiberglass woven roving, 300g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction:

E-glass woven roving Fabric is bidirectional fabric made by 4.5 microns to 17 microns of E-Glass fiber,its high strength ,high modulus ,acid and alkali resistance , high temperature resistance and other properties. often used in protection ,heat insulation ,thermal insulation ,support field . After surface treatment ,it can be made into perfect composite materials . now it is widely used in hand lay up and robot processes to manufacture boats ,vessels ,plane and automotive parts , furniture and sports facilities.

Characteristics of Fiberglass Woven Roving

Woven Roving is a high –performance reinforcement widely used in hand lay-up and machanical production

1) Good moldability & drapability

2) High strength

3) Excellent rollout characteristics

4) Fast wet -out

Specifications:

PRODUCT CODE | WOVEN WEIGHT (OZ/YD) | WOVEN WEIGHT (GSM) | STANDARD WIDTH (INCHES) | ROLL LENGTH (M) | THICKNESS (MM) | LOI % | Moisture Content (%) |

CT-PWR24 | 0.86 | 24 | 50 | 50M | 0.04 | ≤0.80 | ≤0.20 |

CT-PWR48 | 1.71 | 48 | 50 | 50M | 0.06 | ≤0.80 | ≤0.20 |

CT-PWR100 | 2.95 | 100 | 50 | 50M | 0.11 | ≤0.80 | ≤0.20 |

CT-PWR135 | 3.99 | 138 | 50 | 50M | 0.14 | ≤0.80 | ≤0.20 |

CT-PWR200 | 5.9 | 200 | 50 | 50M | 0.18 | ≤0.80 | ≤0.20 |

CT-PWR290 | 8.56 | 290 | 50 | 50M | 0.23 | ≤0.80 | ≤0.20 |

Main features:

1.warp and weft rovings aligned in a parallel,flat manner and uniform tension.

2.densely aligned fiber,providing high dimensional stablity and easy handing.

3.good moldability,fast and complete resin wet-out ,enabling high productivity

4.good transparency and high strength of the composite products

Remark:Woven rovings are available in the width range of 50-3000mm and the weight range of 200-1600g/m2

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Can fiberglass mat tissue be used for insulation in oil refineries?

- No, fiberglass mat tissue is not suitable for insulation in oil refineries. Fiberglass mat tissue is primarily used in construction and automotive industries for reinforcement purposes. It is not designed to withstand the extreme temperatures and corrosive environments found in oil refineries. Instead, insulation materials used in oil refineries are typically made of fire-resistant and chemically resistant materials, such as mineral wool or calcium silicate. These materials are specifically engineered to provide optimal thermal insulation and safety in refinery operations.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Fiberglass mat tissue performs well in high temperatures as it has a high melting point and excellent heat resistance. It retains its strength and structural integrity even when exposed to elevated temperatures, making it suitable for various applications in high-temperature environments.

- Q: Can fiberglass mat tissue be used for making insulation blankets?

- Yes, fiberglass mat tissue can be used for making insulation blankets. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in insulation applications. It offers excellent thermal insulation properties, as well as resistance to fire, moisture, and chemicals. Additionally, fiberglass mat tissue is easy to handle and install, making it an ideal choice for creating insulation blankets that can be used in various industries, such as construction, automotive, and aerospace.

- Q: Does fiberglass mat tissue require any special precautions during storage?

- Yes, fiberglass mat tissue does require some special precautions during storage. Fiberglass is a delicate material and can be easily damaged if not stored properly. Here are some precautions to consider: 1. Keep it dry: Fiberglass mat tissue should be stored in a dry and moisture-free environment. Moisture can cause the material to lose its strength and integrity. 2. Avoid direct sunlight: UV rays from sunlight can degrade fiberglass over time. Store the material in a cool, shaded area away from direct sunlight to prevent any damage. 3. Protect from dust and dirt: Fiberglass mat tissue should be stored in a clean and dust-free environment. Dust and dirt particles can get embedded in the material, making it less effective. 4. Avoid extreme temperatures: Extreme heat or cold can also affect the quality of fiberglass mat tissue. It is best to store it in a temperature-controlled environment to prevent any damage. 5. Use proper packaging: If the fiberglass mat tissue comes with packaging, it is recommended to keep it in its original packaging to provide an additional layer of protection. If not, consider using a durable and moisture-resistant wrapping material. By following these precautions, you can ensure that your fiberglass mat tissue remains in good condition during storage and is ready for use when needed.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue can have a significant impact on its transportation process. The weight of the roll determines the ease of handling and the logistics required for transportation. Firstly, a heavier roll weight can make it more challenging to move and handle the fiberglass mat tissue. If the roll is too heavy, it may require specialized equipment or machinery for loading and unloading, such as forklifts or cranes. This can add complexity and cost to the transportation process. Moreover, the weight of the roll also affects the packaging and storage requirements during transportation. Heavier rolls may require sturdier packaging materials and additional precautions to ensure their stability and prevent any damage during transit. This can include using pallets, strapping, or other securing methods to prevent the roll from shifting or falling during transportation. The weight of the roll also impacts the overall cost of transportation. Heavier rolls can increase shipping costs, as carriers often charge based on weight. Additionally, the weight of the roll can affect the number of rolls that can be transported in a single shipment, which can impact the efficiency and cost-effectiveness of the transportation process. In summary, the roll weight of fiberglass mat tissue plays a crucial role in its transportation. It affects the ease of handling, packaging requirements, and overall cost of transportation. Therefore, it is essential to consider the roll weight when planning and organizing the logistics for transporting fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation purposes?

- Yes, fiberglass mat tissue can be used for insulation purposes. It is commonly used as a layer in insulation systems to provide thermal resistance and enhance the overall insulation performance.

- Q: Can fiberglass mat tissue be used for repairing fiberglass kayaks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass kayaks. It is commonly used as a reinforcement material in fiberglass repairs due to its strength and ability to conform to curved surfaces.

- Q: What is fiberglass mat tissue made of?

- Fiberglass mat tissue is made of fine strands of glass fibers that are woven together to form a thin, flexible fabric-like material. These glass fibers are typically made from molten glass that is drawn into very thin filaments and then coated with a binding agent to improve strength and durability. The woven structure of the fiberglass mat tissue helps to provide reinforcement and stability to various materials and products, making it an ideal choice for applications such as insulation, roofing, and composite materials.

- Q: How does the strength of fiberglass mat tissue compare to other reinforcement materials?

- The strength of fiberglass mat tissue is comparable, if not superior, to other reinforcement materials. It offers excellent tensile strength, high resistance to corrosion, and good thermal insulation properties. Additionally, it is lightweight, flexible, and cost-effective, making it a popular choice in various industries such as construction, automotive, and aerospace.

- Q: Can fiberglass mat tissue be used in structural applications?

- Indeed, structural applications can make use of fiberglass mat tissue. This lightweight and flexible material is frequently employed as reinforcement in construction and engineering endeavors. It is often combined with resin or concrete to enhance the structural integrity of diverse components. The remarkable strength-to-weight ratio of fiberglass mat tissue renders it exceptionally fitting for reinforcing walls, roofs, and floors. Furthermore, its resistance to corrosion, moisture, and chemicals allows for its utilization in diverse environments. The wide-ranging applicability and enduring nature of fiberglass mat tissue contribute to its widespread preference in structural applications.

Send your message to us

Fiberglass Mat Tissue - e-glass fiberglass woven roving, 300g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords