E-glass Chopped Strand Mat Emulsion/300g/450g/600g

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-glass Chopped Strand Mat Emulsion/300g/450g/600g

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

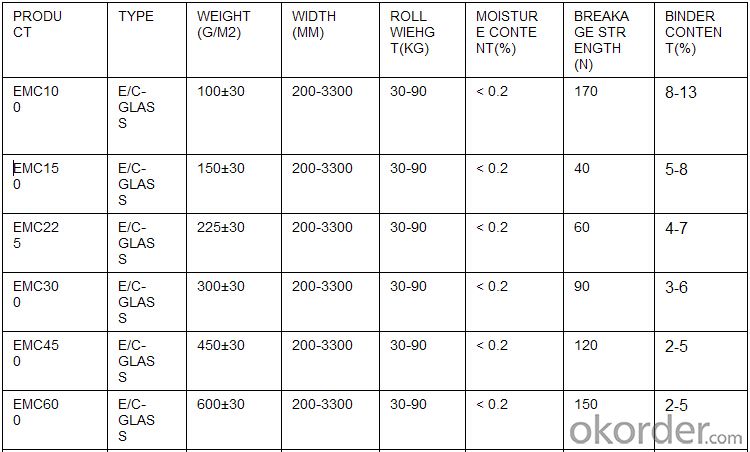

Technical Data:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: How does fiberglass mat tissue perform in terms of UV resistance?

- Fiberglass mat tissue generally has good UV resistance. UV resistance refers to the ability of a material to withstand the harmful effects of ultraviolet radiation from the sun without degrading or deteriorating. Fiberglass mat tissue is usually manufactured using a combination of fiberglass and a binder material, which provides strength and integrity to the tissue. The fiberglass component in the mat tissue provides inherent UV resistance. Fiberglass is known for its durability and ability to resist degradation from UV exposure. It is a non-porous material that does not absorb UV radiation, making it less susceptible to damage caused by the sun's rays. Additionally, some manufacturers may apply a UV-resistant coating or treatment to the fiberglass mat tissue to enhance its UV resistance. This coating or treatment can further protect the tissue from the damaging effects of prolonged exposure to UV radiation. Overall, fiberglass mat tissue performs well in terms of UV resistance. It is a durable material that can withstand the harmful effects of UV radiation, making it suitable for applications where prolonged exposure to sunlight is expected. However, it is important to note that the specific UV resistance of fiberglass mat tissue may vary depending on the manufacturing process, quality of materials used, and any additional coatings or treatments applied.

- Q: Is fiberglass mat tissue suitable for insulation in cold storage facilities?

- Yes, fiberglass mat tissue is suitable for insulation in cold storage facilities. It offers excellent thermal insulation properties and is commonly used in such environments to maintain low temperatures and prevent heat transfer. Additionally, fiberglass is resistant to moisture, which is important in cold storage facilities where condensation can occur.

- Q: What is the moisture resistance of fiberglass mat tissue?

- Fiberglass mat tissue boasts a generally high level of moisture resistance. It is typically crafted from tightly woven fiberglass strands, resulting in a dense and water-resistant surface. This characteristic renders it exceptionally effective in situations where moisture exposure is prevalent, particularly in the construction field for roofing, insulation, and waterproofing applications. Furthermore, manufacturers frequently apply special coatings or additives to enhance its moisture resistance, thereby increasing its durability and reliability in wet or humid environments. As a result of this advantageous feature, fiberglass mat tissue finds extensive utilization across numerous industries.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Yes, fiberglass mat tissue can be used for bridge construction. Fiberglass mat tissue is a versatile material that offers several advantages. It is lightweight yet strong, making it suitable for use in bridge construction where weight considerations are important. Additionally, fiberglass mat tissue is highly durable and resistant to corrosion, which is crucial for the longevity and maintenance of bridges. It can also be easily molded into various shapes, allowing for flexibility in bridge design. Moreover, fiberglass mat tissue has good impact resistance and excellent fatigue performance, ensuring the bridge's ability to withstand heavy loads and constant traffic. Overall, fiberglass mat tissue is a reliable and cost-effective material for bridge construction.

- Q: What are the different types of fiberglass mat tissue available?

- There are several different types of fiberglass mat tissues available, each with its own unique characteristics and applications. Some of the most common types include: 1. Chopped Strand Mat (CSM): This is the most basic and widely used type of fiberglass mat tissue. It consists of randomly oriented chopped strands of fiberglass held together with a binder. CSM is typically used in applications where strength and resilience are important, such as boat building and automotive parts manufacturing. 2. Continuous Filament Mat (CFM): Unlike CSM, CFM is made from continuous strands of fiberglass that are woven into a mat. This type of fiberglass mat tissue offers excellent tensile strength and dimensional stability, making it ideal for applications that require high strength and stiffness, such as aerospace components and wind turbine blades. 3. Surface Veil Mat: Surface veil mat is a very thin and lightweight type of fiberglass mat tissue that is used primarily for surface finishing and reinforcement. It is typically applied as a final layer in composite laminates to improve the surface smoothness and water resistance. 4. Stitched Mat: Stitched mat is made by interweaving continuous strands of fiberglass with a stitching thread. This construction provides increased strength and improved drapability, making it easier to conform to complex shapes. Stitched mat is commonly used in applications that require a combination of strength and flexibility, such as in the production of pipes and tanks. 5. Binderless Mat: Binderless mat is a specialty type of fiberglass mat tissue that does not contain any binders or resins. Instead, the fibers are mechanically bonded together using a needling process. This makes binderless mat highly resistant to chemical attack and suitable for use in corrosive environments, such as chemical storage tanks and pipes. These are just a few examples of the different types of fiberglass mat tissues available. The choice of which type to use depends on the specific requirements of the application, including strength, flexibility, surface finish, and resistance to various environmental factors.

- Q: How does fiberglass mat tissue compare to polyurethane insulation?

- Fiberglass mat tissue and polyurethane insulation are two commonly used materials in the construction industry, but they have distinct differences in terms of composition, performance, and applications. Fiberglass mat tissue is made from glass fibers that are woven into a mat-like structure. It is primarily used as a reinforcement material in various applications such as roofing, wall insulation, and fiberglass composites. The main advantage of fiberglass mat tissue is its high tensile strength, which provides excellent structural support and durability. It is also resistant to fire and chemicals, making it a suitable choice for applications where safety is a concern. On the other hand, polyurethane insulation is a foam material that is known for its excellent thermal insulation properties. It is commonly used in buildings to reduce heat transfer and improve energy efficiency. Polyurethane insulation has a high R-value, which indicates its ability to resist heat flow. This makes it an ideal choice for insulation purposes, especially in areas with extreme temperature conditions. Additionally, polyurethane insulation is lightweight, easy to install, and has good moisture resistance. When comparing fiberglass mat tissue to polyurethane insulation, it is important to consider the specific needs and requirements of the project. Fiberglass mat tissue is more suitable for applications that require structural reinforcement, such as roofing and composite materials. It provides excellent strength and durability, making it a preferred choice for such applications. On the other hand, polyurethane insulation is more effective in terms of thermal insulation. It offers superior heat resistance and has a higher R-value compared to fiberglass mat tissue. Therefore, if the primary goal is to improve energy efficiency and reduce heat transfer, polyurethane insulation would be the better choice. Overall, fiberglass mat tissue and polyurethane insulation have their own strengths and weaknesses. The decision on which material to use should be based on the specific requirements of the project, such as structural support or thermal insulation needs. Consulting with a professional and considering factors such as budget, environmental impact, and local building codes can help in making an informed decision.

- Q: What are the potential environmental impacts of using fiberglass mat tissue?

- The potential environmental impacts of using fiberglass mat tissue include the release of harmful airborne particles during production and installation, which can contribute to air pollution and respiratory issues. Additionally, the disposal of fiberglass mat tissue can pose challenges as it is not biodegradable and may contribute to landfill waste.

- Q: Can fiberglass mat tissue be used for reinforcing pipes?

- Yes, fiberglass mat tissue can be used for reinforcing pipes. Fiberglass mat tissue is made of fine glass fibers that are randomly oriented, giving it excellent strength and flexibility. This makes it an ideal material for reinforcing various structures, including pipes. When applied to the surface of a pipe, the fiberglass mat tissue helps to increase its overall strength and durability, preventing cracks and leaks. Additionally, fiberglass mat tissue is resistant to corrosion, making it suitable for use in pipes that carry corrosive substances. Overall, fiberglass mat tissue is a reliable choice for reinforcing pipes and ensuring their long-term performance.

- Q: Can fiberglass mat tissue be used for making insulation boards?

- Yes, fiberglass mat tissue can be used for making insulation boards. The tissue provides strength, stability, and reinforcement to the insulation material, making it an effective choice for insulation board manufacturing.

- Q: Is fiberglass mat tissue resistant to corrosion?

- Indeed, corrosion is not a concern for fiberglass mat tissue as it is comprised of non-metallic elements like glass fibers, unlike metals which are susceptible to rust and corrosion. This quality renders fiberglass mat tissue highly suitable for various purposes that demand resistance against corrosion, such as reinforcing concrete structures within the construction sector or for boat building in the marine industry. Furthermore, fiberglass mat tissue exhibits resistance towards chemicals, moisture, UV rays, and extreme temperatures, thereby augmenting its strength and longevity.

Send your message to us

E-glass Chopped Strand Mat Emulsion/300g/450g/600g

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords