Fiberglass Facing E-Glass Emulsion Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber E-glass Emulsion Chopped Strand Mat

Introduction:

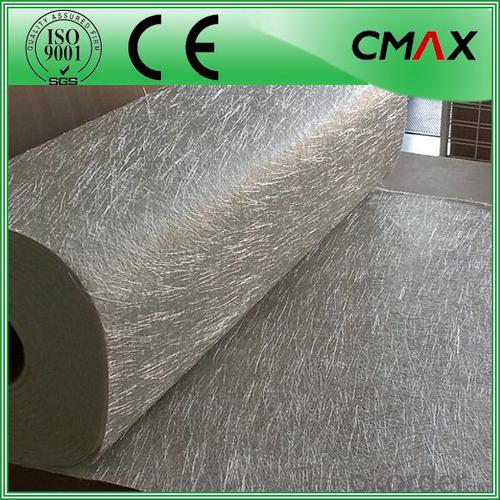

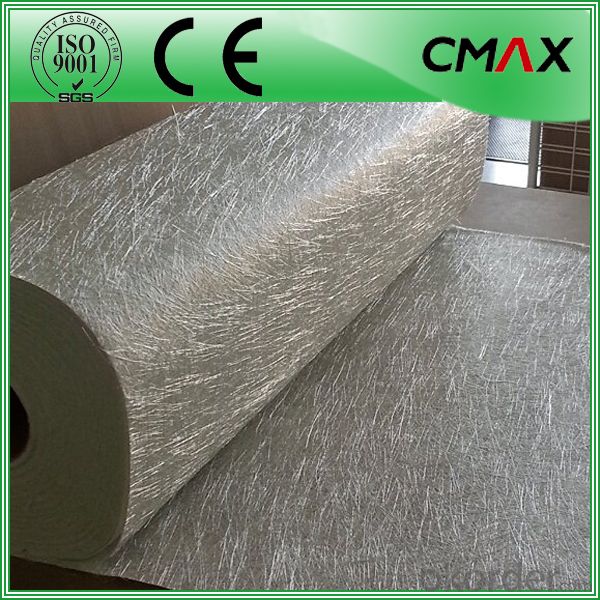

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

1. Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2. Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3. Excellent flexibility ensures good mold ability with no spring back at sharp angles.

4. Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhances productivity and mechanical properties of the end products.

5. The composite products have high dry and wet tensile strength and good transparency.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: Is it possible to utilize black fiberglass tissue for cleaning hard surfaces?

- <p>Yes, black fiberglass tissue can be used as a cleaning tool for hard surfaces. It is known for its durability and abrasive properties, which make it effective in removing dirt, grime, and even rust. However, it's important to use it with caution as it can scratch softer surfaces. Always test a small, inconspicuous area first to ensure it doesn't damage the surface.</p>

- Q: This question asks if there is any difference between black fiberglass tissues that are domestically produced and those that are imported.

- <p>Yes, there can be differences between domestic and imported black fiberglass tissues. These differences may include quality standards, manufacturing processes, material composition, and cost. Domestic products are often more readily available and may be subject to local regulations and standards, while imported products might have different certifications or comply with international standards. Additionally, the cost can vary due to factors like transportation, import duties, and market demand. It's important to consider the specific application and requirements when choosing between domestic and imported black fiberglass tissues.</p>

- Q: What are the potential drawbacks of using fiberglass facing?

- One potential drawback of using fiberglass facing is its susceptibility to damage and breakage. Unlike other materials like metal or concrete, fiberglass can be easily cracked or shattered if not handled with care. Another drawback is that fiberglass facing is not as strong or durable as some alternative materials, which could limit its use in certain applications that require higher strength or resistance to extreme conditions. Additionally, fiberglass can be more expensive compared to other materials, which may impact the overall cost of a project.

- Q: Explain the distinction between black and white fiberglass tissue, including their composition and potential applications.

- <p>Black and white fiberglass tissue are both made from glass fibers, but they differ in color and certain properties. Black fiberglass tissue typically contains carbon black, which provides UV protection and can improve the material's resistance to weathering. It is often used in applications where durability and resistance to sunlight are important, such as in the construction of boats and outdoor structures. White fiberglass tissue, on the other hand, does not contain carbon black and is generally used in applications where aesthetics are a priority, such as in the automotive and aerospace industries. It is also used in situations where the absence of color is beneficial, such as in the production of translucent composites.</p>

- Q: What kind of black fiberglass tissue is recommended for use in cold weather conditions?

- <p>Yes, there is a specific type of black fiberglass tissue designed for use in cold climates. This type of fiberglass is often referred to as 'weather-resistant' or 'cold-resistant fiberglass.' It is engineered to maintain its strength and flexibility in low temperatures, preventing brittleness and breakage. This special formulation is crucial for applications where the material will be exposed to freezing temperatures and harsh weather conditions, ensuring durability and longevity.</p>

- Q: Is it possible to utilize black fiberglass tissue in the creation of garments?

- <p>While it is technically possible to use black fiberglass tissue for clothing, it is not a common practice due to its rigidity and lack of flexibility. Fiberglass is typically used in construction and insulation applications. For clothing, materials that are soft, breathable, and flexible are preferred. If you're looking for a durable fabric, consider alternatives like Kevlar or other synthetic fibers designed for clothing.</p>

- Q: Is it possible to utilize black fiberglass tissue in the construction industry?

- <p>Yes, black fiberglass tissue, also known as black fiber-reinforced polymer (FRP), can be used in construction. It is valued for its high strength-to-weight ratio, corrosion resistance, and durability. Black fiberglass is often used in reinforcing concrete structures, as a component in composite materials, and for strengthening or repairing existing structures. It is also used in the creation of lightweight and strong building materials, such as rebar replacements and for cladding due to its resistance to harsh weather conditions.</p>

- Q: This question asks for the specific measurement of the thickness of black fiberglass tissue.

- <p>The thickness of black fiberglass tissue can vary depending on the specific product and manufacturer. Generally, it ranges from 0.1mm to 2mm. However, it's important to note that the exact thickness should be confirmed by referring to the product specifications or by contacting the manufacturer directly, as different applications may require different thicknesses.</p>

- Q: Is it possible to utilize black fiberglass tissue as a flooring material in residential settings?

- <p>Yes, black fiberglass tissue can be used for flooring in residential homes. It is known for its durability, resistance to moisture and chemicals, and is often used in areas prone to water or chemical exposure. However, it may not be as aesthetically pleasing as traditional flooring options and can be slippery when wet, so it's important to consider these factors when deciding on its use for residential flooring.</p>

- Q: The user is asking if they can use their old towels as a replacement for black fiberglass tissues.

- <p>While it might be tempting to repurpose old towels as a substitute for black fiberglass tissues, it's not advisable. Black fiberglass tissues are specifically designed for certain applications due to their unique properties, such as heat resistance and strength. Old towels, even if they are black, lack these specific characteristics and may not provide the same level of performance or safety. It's best to use materials as intended to ensure effectiveness and avoid potential issues.</p>

Send your message to us

Fiberglass Facing E-Glass Emulsion Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords