E20 Emulsion E Glass Fiber Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 560 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E20 Emulsion Chopped Strand Mat

E20 Emulsion Chopped Strand Mat is made of randomly distributed chopped E6 glass strands held together by an emulsion binder. E20 is suitable to reinforce unsaturated polyester, vinyl ester,epoxy and phenolic resins.

E20 is designed mainly for use in the hand lay-up process and also suitable for use in filament winding and continuous laminating processes. Its end-use applications include boats, bath equipment, automotive parts, chemical corrosion resistant pipes, tanks, cooling towers and building components.

Product Features:

◎ Good conformability.

◎ Good wet-through and fast wet-out in resins, rapid air lease, reducing rolling out time and increasing productivity.

◎ Low resin consumption.

◎ High mechanical strength of parts.

◎ Superior acid corrosion resistance.

Product Specifications:

Property | Area Weight(g/m²) | Moisture Content(%) | Size Content(%) | Breakage Strength(N) |

Methods | ISO 3374 | ISO 3344 | ISO 1887 | ISO 3342 |

EMC225 | 225(1±6%) | ≤0.15 | 4.4(1±31%) | ≥80 |

EMC300 | 300(1±6%) | ≤0.15 | 4.0(1±31%) | ≥100 |

EMC375 | 375(1±6%) | ≤0.15 | 3.8(1±31%) | ≥120 |

EMC450 | 450(1±6%) | ≤0.15 | 3.7(1±31%) | ≥140 |

EMC600 | 600(1±6%) | ≤0.15 | 3.5(1±31%) | ≥160 |

EMC900 | 900(1±6%) | ≤0.15 | 3.3(1±31%) | ≥200 |

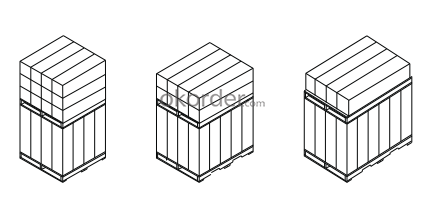

Packaging:

Each Emulsion Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 90mm. The roll outside diameter is approximately 265mm. Each roll is wrapped up in plastic film and then packed in a cardboard box. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Storage:

Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture-proof area. The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively. It is best if the product is used within 6 months after production date.

- Q: Can fiberglass chopped strand be used in construction?

- Yes, fiberglass chopped strand can be used in construction. It is commonly used as a reinforcement material in various construction applications such as concrete, roofing, insulation, and composite panels. It enhances the strength, durability, and fire resistance of the construction materials.

- Q: Can fiberglass chopped strand be used in the production of aerospace structures?

- Yes, fiberglass chopped strand can be used in the production of aerospace structures. It is commonly used as a reinforcement material in composite materials for various aerospace applications, including aircraft parts and components. The high strength-to-weight ratio and excellent mechanical properties of fiberglass make it suitable for enhancing the structural integrity and performance of aerospace structures.

- Q: What are the shear strength properties of fiberglass chopped strand?

- The shear strength properties of fiberglass chopped strand are affected by various factors, including the length and alignment of the strands, the resin matrix used, and the manufacturing process. In general, fiberglass chopped strand demonstrates good shear strength due to the interlocking nature of the randomly-oriented strands. The length of the chopped strands has a significant impact on shear strength. Longer strands tend to offer higher shear strength as they can distribute the applied load over a larger area. However, shorter strands may be preferred for specific applications where improved flow and easier processing are desired. The alignment of the chopped strands also influences shear strength. Randomly-oriented strands provide better interlocking and resistance to shear forces compared to aligned or unidirectional fibers. The random orientation enables the distribution of forces in multiple directions, enhancing the overall shear strength of the material. The resin matrix used in fiberglass chopped strand composites also plays a crucial role in determining shear strength properties. The resin should adhere well to the fibers and provide sufficient bonding strength to withstand shear loads. Epoxy resins, for example, are commonly used due to their excellent adhesion properties and high shear strength. The manufacturing process employed to produce fiberglass chopped strand can also impact shear strength properties. Factors such as compaction pressure, curing temperature, and post-processing techniques can influence the final shear strength of the material. Careful control of these parameters during manufacturing can optimize the shear strength properties of fiberglass chopped strand. In conclusion, fiberglass chopped strand demonstrates favorable shear strength properties due to the interlocking nature of the strands and the bonding strength provided by the resin matrix. However, it is important to consider the specific requirements of the application and select the appropriate fiber length, alignment, resin matrix, and manufacturing process to ensure optimal shear strength performance.

- Q: What are the typical fiber lengths used in fiberglass chopped strand?

- The typical fiber lengths used in fiberglass chopped strand can vary depending on the specific application and requirements. However, most commonly, the fiber lengths range from 3-6 mm (1/8-1/4 inch). These shorter fiber lengths are preferred as they provide better dispersion and distribution within the resin matrix, resulting in improved overall strength and performance of the fiberglass composite. Additionally, shorter fiber lengths also help to minimize the potential for fiber entanglement and clumping during processing. However, it is important to note that longer fiber lengths can also be used in certain specialized applications where increased strength or specific properties are desired. Ultimately, the choice of fiber length in fiberglass chopped strand is determined by the specific needs and characteristics of the intended end use.

- Q: Can fiberglass chopped strand be used in the production of consumer packaging?

- Indeed, fiberglass chopped strand can be utilized in the manufacturing of consumer packaging. Serving as a reinforcement material, fiberglass chopped strand consists of small pieces created by chopping strands of fiberglass. It finds wide application as a reinforcement material in various fields, including consumer packaging. When employed in consumer packaging, fiberglass chopped strand imparts additional strength and durability to the packaging material. This aids in preventing the packaging from tearing or breaking, thereby ensuring the secure and protected containment of the product within. Furthermore, fiberglass chopped strand enhances the overall structural integrity of the packaging, rendering it more resistant to external pressures and impacts. Moreover, fiberglass chopped strand possesses the qualities of being lightweight and versatile, making it compatible with diverse types of consumer packaging materials. It can be effortlessly incorporated into plastics, paper, or other packaging materials during the manufacturing process. Consequently, this allows for flexibility in packaging design and customization while still providing the essential strength and durability. In summary, the utilization of fiberglass chopped strand in the production of consumer packaging serves to elevate the quality and performance of the packaging material, effectively meeting the requirements and expectations of consumers.

- Q: Is fiberglass chopped strand suitable for applications requiring high vibration resistance?

- Yes, fiberglass chopped strand is suitable for applications requiring high vibration resistance. Fiberglass is known for its excellent mechanical properties, including high tensile strength and stiffness. The chopped strand form provides additional benefits, such as improved dispersion and easier handling during application. These characteristics make fiberglass chopped strand an ideal material for applications that are subjected to high levels of vibration, such as automotive parts, boat hulls, and aerospace components. The fibers' ability to absorb and dissipate vibrations helps to reduce stress and prevent fatigue failure in these demanding environments. Additionally, fiberglass chopped strand is highly versatile and can be combined with other materials to further enhance its vibration resistance properties.

- Q: Can fiberglass chopped strand be used in the production of insulation panels?

- Yes, fiberglass chopped strand can be used in the production of insulation panels. Fiberglass chopped strand is commonly used as a reinforcement material in various composite applications, including insulation panels. It provides strength, durability, and thermal insulation properties to the panels. The chopped strands are mixed with a binder material and then formed into panels using various manufacturing techniques such as compression molding or pultrusion. The resulting insulation panels offer excellent thermal insulation properties, low thermal conductivity, and high resistance to heat transfer, making them suitable for a wide range of applications in the construction and industrial sectors.

- Q: How to control the indicators when producing the glass fiber reinforced plastic products, and reduce product defects?

- Resins require low viscosity and are easy to operate manually. (2) The raw material is unsaturated polyester resin. Pay more attention to the lap joint when laying up. Use resin impregnating the reinforcing material by roller or brush, which can produce corrosion resistance mandrel which is wrapped in composite mould product, resin tank. (3) Advantages 1) As the fiber is directly laid in liner way. It can prevent the wrinkles, but the cost of the mandrel is too high. Although the composite products are usually single shell. When producing tube tank, use roving. (4) Disadvantages 1) It belongs to labour intensive production. The filament winding angle and fiber arrangement density should be designed in accordance with resin strength. Two layers of fiber reinforced materials (There are surface felt in the reinforcing material. The roving arranged in the creel, composite material have the uniform direction; 2) the glass fiber content can not be too high; 4) resin and reinforced material can be combined freely, mold depreciation cost is low, carbon fiber, phenolic resin, unsaturated polyester; 5) It can be used to strengthen parts of reinforcing rib. Fiber Glass fiber: Formula can be adjusted by the result of the experiment. Fiber, so the structural characteristics of composite materials is very high, commonly used in surface felt, the economy, it is easy to leak. Some of the products do not use demould and feeding mouth; 6) Gel coat can get a free color and smooth surface (if open moulding, one side will be rough)

- Q: What are the typical creep properties of fiberglass chopped strand composites?

- Fiberglass chopped strand composites possess certain characteristics that are commonly associated with creep. Creep refers to the tendency of a material to deform and relax under a continuous load or stress over an extended period of time. In comparison to metals or polymers, fiberglass chopped strand composites demonstrate relatively low levels of creep. This can be attributed to the reinforcing qualities of the fiberglass strands, which provide strength and rigidity to the composite. Various factors influence the occurrence of creep in fiberglass chopped strand composites, including temperature, humidity, and the magnitude of the applied load. When exposed to higher temperatures, the creep rate tends to increase as the matrix material softens, enabling greater deformation. Similarly, elevated levels of humidity can hasten creep as moisture weakens the matrix and diminishes the overall composite strength. The level of applied load or stress also impacts the creep behavior of fiberglass chopped strand composites. Higher loads typically result in higher creep rates, as the material undergoes more significant deformation under the continuous stress. Nevertheless, the reinforcing nature of the fiberglass strands helps mitigate creep by dispersing the load and preventing localized deformations. In summary, fiberglass chopped strand composites exhibit relatively low creep characteristics, making them suitable for applications that necessitate dimensional stability and resistance to prolonged stress. However, it is essential to consider the specific environmental conditions and load requirements to ensure that the material's performance aligns with the desired expectations.

- Q: Can fiberglass chopped strand be used in sporting goods applications?

- Yes, fiberglass chopped strand can be used in sporting goods applications. It is commonly used to reinforce various components in sporting goods such as hockey sticks, tennis rackets, golf clubs, and even surfboards. The fiberglass adds strength and durability to these products, making them more suitable for rigorous use.

Send your message to us

E20 Emulsion E Glass Fiber Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 560 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords