Dux Geotextiles - Geotextile Fabric for Filtration and Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1,Specification of PP/PET Nonwoven Geotextile Fabric

1)Area Weight: 100g/m2-1500g/m2

2) Width: Within 6 m (1m-6m)

3) Length: 50m-100m/roll (as per request)

4) Material: Polypropylene or polyester

2,Specialities of PP/PET Nonwoven Geotextile Fabric

1) Staple fibers needle punched nonwoven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment. It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

3,Package of PP/PET Nonwoven Geotextile Fabric

Each roll is wrapped with plastic film. Or as per customer's request

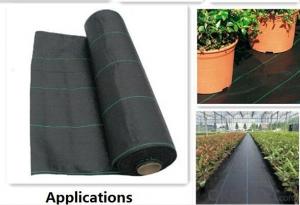

4,Application of PP/PET Nonwoven Geotextile Fabric

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: How do geotextiles contribute to sustainable construction practices?

- Geotextiles contribute to sustainable construction practices by providing a range of beneficial functions. They can stabilize soil, prevent soil erosion, and enhance drainage systems, which reduces the need for excessive excavation and reduces the amount of construction materials required. Geotextiles also promote environmental protection by filtering out pollutants and preventing their migration into surrounding areas. Additionally, they prolong the lifespan of infrastructure, reducing the need for frequent repairs and replacements, thereby minimizing the consumption of resources and energy. Overall, geotextiles play a vital role in sustainable construction practices by promoting efficiency, cost-effectiveness, and environmental conservation.

- Q: Can geotextiles be used for soil reinforcement in embankments?

- Yes, geotextiles can be used for soil reinforcement in embankments. Geotextiles are commonly used in civil engineering projects to improve the stability and strength of soil structures. They are effective in preventing soil erosion, enhancing drainage, and distributing loads, making them suitable for reinforcing embankments and preventing slope failures.

- Q: Filament, preferably concrete construction

- Tianhai new material filament geotextile case analysis of water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: What is the filament single-sided singeing geotextile

- Filament single-sided singeing geotextile is through a series of hot-rolling process will filament geotextile side of the filament fiber roll hot filament geotextile surface of the unity, thereby increasing the filament geotextile non-slip, anti- Tear resistance. Filament singeing geotextile is generally used for landfill, tailings and other projects with rough surface geomembrane with the use of friction coefficient to increase and improve anti-skid performance. Filament single-sided singeing geotextile is the first production of finished filament geotextile, and then through the professional equipment for single-sided singeing.

- Q: What are the key considerations for geotextile installation in areas with high seismic activity?

- Some key considerations for geotextile installation in areas with high seismic activity include selecting geotextiles that have high tensile strength and flexibility to withstand ground movement during earthquakes. It is also important to properly anchor the geotextiles to prevent movement or displacement. Additionally, the design and installation of the geotextiles should take into account the potential for liquefaction and soil settlement during seismic events to ensure their effectiveness in stabilizing the ground and preventing erosion. Regular inspections and maintenance should be conducted to identify any damage or displacement caused by seismic activity and address them promptly.

- Q: Can plant roots penetrate geotextiles? Which kind of similar material can keep soil and water and let the plant roots pass through it?

- Surely, geotextile is polyester or polypropylene. Do you hear the bag? With this not to solve the ah, green grass for the special, but also to maintain soil and water. I am doing this specifically.

- Q: How long do geotextiles last?

- Geotextiles can last anywhere from 5 to 25 years, depending on various factors such as the quality of the material, environmental conditions, and the specific application they are used for.

- Q: Can the geotextile of the filter layer be constructed?

- Hello, you can construction, I am specializing in the production of geosuction impermeable materials, a professional welding construction team, the most cost-effective, wish smooth

- Q: Are geotextiles commonly used in mining tailings management?

- Yes, geotextiles are commonly used in mining tailings management.

- Q: Are geotextiles suitable for use in contaminated soil remediation projects?

- Yes, geotextiles are suitable for use in contaminated soil remediation projects. Geotextiles have been proven to be effective in separating and stabilizing soil layers, preventing soil erosion, and controlling sedimentation. They can also act as a barrier to prevent the spread of contaminants, while allowing for proper drainage and filtration. Additionally, geotextiles are durable, cost-effective, and environmentally friendly, making them a suitable choice for remediation projects.

Send your message to us

Dux Geotextiles - Geotextile Fabric for Filtration and Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords