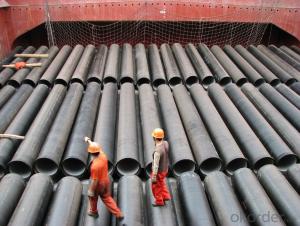

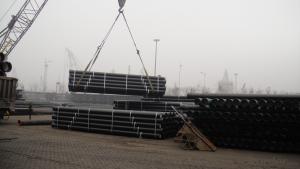

Ductile Iron Pipe For Water Project with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

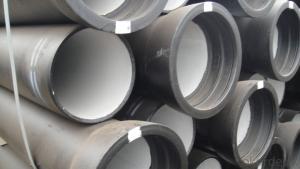

- Q: Are ductile iron pipes suitable for potable water distribution systems?

- Yes, ductile iron pipes are suitable for potable water distribution systems. Ductile iron is a type of cast iron that is known for its high strength and durability, making it an excellent choice for conveying drinking water. These pipes are resistant to corrosion, which is essential for maintaining the quality and safety of potable water. Additionally, ductile iron pipes have a smooth interior surface, which helps to minimize the accumulation of sediments and biofilms that can affect water quality. They also have the ability to withstand high pressure and temperature changes, making them suitable for various potable water distribution systems. Overall, ductile iron pipes are a reliable and widely used option for ensuring the delivery of safe and clean drinking water to communities.

- Q: How are ductile iron pipes protected against abrasion or wear?

- Ductile iron pipes are protected against abrasion or wear through various methods and protective coatings. One of the most common methods is the application of cement mortar lining on the inner surface of the pipe. The cement mortar creates a smooth and hard layer that resists the effects of abrasion and wear caused by the flowing water or other materials passing through the pipe. Additionally, ductile iron pipes can be externally protected by applying a bituminous or epoxy coating. These coatings provide a barrier against external factors such as soil or chemicals that may cause wear or corrosion. The coating acts as a protective layer, preventing direct contact between the iron pipe and the surrounding environment. Moreover, for areas with severe abrasion or wear conditions, special linings or coatings can be applied. Polyethylene encasement or polyurethane lining can be used to provide enhanced protection against abrasion, particularly in areas where the pipe is exposed to high levels of turbulence or abrasive materials. In some cases, ductile iron pipes can also be reinforced with additional materials such as fiberglass or steel wire to increase their resistance to abrasion or wear. These reinforcements provide an extra layer of protection, strengthening the pipe and reducing the likelihood of damage. Overall, ductile iron pipes are designed with a combination of protective measures to ensure their durability and resistance to abrasion or wear. These measures include cement mortar linings, protective coatings, special linings or coatings for severe conditions, and reinforcements. These protective methods help extend the lifespan of the pipes and maintain their functionality even in harsh environments.

- Q: Can ductile iron pipes be used for irrigation systems?

- Yes, ductile iron pipes can be used for irrigation systems. Ductile iron pipes are commonly used in various applications, including water supply systems and irrigation systems. They are known for their strength, durability, and corrosion resistance, making them suitable for transporting water in irrigation systems.

- Q: What are the specifications for the installation of water ball iron pipes?

- The T type interface pipe shall be supported by a pier in the vertical or horizontal direction. The size of the pier should be calculated according to the factors such as pipe diameter, angle of rotation and working pressure. 4, the transmission of drinking water, the pipeline should not pass through the poison contaminated areas, such as the need to pass through, should take protective measures.

- Q: What is the expected bedding and backfill requirements for ductile iron pipes?

- The expected bedding and backfill requirements for ductile iron pipes are vital for ensuring the longevity and proper functioning of the pipe system. Ductile iron pipes are known for their durability and strength, but they still require careful installation to prevent any potential damage or compromised performance. The bedding requirements for ductile iron pipes involve providing a stable and uniform support system to distribute the loads and stresses from the surrounding soil. The pipe should be surrounded by a bedding material that is free from rocks, debris, or any sharp objects that could potentially cause damage. The bedding material should also have sufficient compaction to prevent settlement or shifting that could lead to misalignment or pipe failure. Typically, the bedding material used for ductile iron pipes is a granular material, such as sand or fine aggregate, with a thickness of at least 6 inches. This material should be placed beneath and around the pipe in a uniform manner to provide a continuous support system. Additionally, the bedding material should be compacted to at least 90% of the maximum dry density to ensure proper stability and load distribution. Backfill requirements for ductile iron pipes involve the material used to fill the remaining space around the pipe after the bedding has been installed. The backfill material should also be free from rocks, debris, or sharp objects that could potentially damage the pipe. It should provide support and protection to the pipe while allowing for proper compaction and settling. The backfill material for ductile iron pipes is typically a granular material, such as sand or fine aggregate, with a maximum particle size of 1 inch. The backfill material should be placed and compacted in layers, ensuring that the compaction is done uniformly and evenly around the pipe. The compaction should be sufficient to prevent settlement or shifting of the backfill material, which could lead to pipe damage or misalignment. In summary, the expected bedding and backfill requirements for ductile iron pipes involve using a granular material that is free from rocks, debris, or sharp objects. The material should be placed and compacted in a uniform manner to provide stable support and protection to the pipe. Adhering to these requirements will help ensure the proper functioning and longevity of ductile iron pipe systems.

- Q: What is the excavation width of ductile iron pipes with diameters greater than 1400?

- When the condition does not allow enough slope, it is necessary to do wall protection and other means to ensure safetyRemind me, such a big pipe, dig deep in two ways. One is the depth diameter (range at the junction of 1.6 m in length and 500 for manholes and operation. The lower bolt assembly when) there is a depth diameter plus 500. and then in the trench laying branch the pier, installed after the fine stone tamped backfill.Can also be buried directly with the pipe diameter, and then put into the assembly. This method requires a large space on the ground, otherwise, the volume is too large after assembly, weight is too heavy, may cause damage to the pipeline and personnel injuries

- Q: Can ductile iron pipes be used for underground utilities?

- Yes, ductile iron pipes can be used for underground utilities. Ductile iron is a strong and durable material that can withstand the pressure and load requirements of underground applications. It is commonly used for water and wastewater systems, gas distribution, and other underground utility infrastructure.

- Q: Will nodular cast iron pipes rust?

- Although the wall has a long flow of water, but oxygen scarce, compared with the outer wall is not easy to corrosion, but there is cement lining is necessary.

- Q: A tube is used only in ductile iron pipes, isn't it?

- Ductile weakness: ductile cast iron pipes connected by human factors such as the operation level of responsibility, influence, construction not convenient. The advantages of PE PE PE pipe has good corrosion resistance and its anti inorganic performance than that of the metal pipe is much stronger in the buried without corrosion, construction convenient. Small diameter PE pipe in the price performance ratio is better than that of steel and ductile iron.PE tube have disadvantages: benzene, gasoline, carbon tetrachloride and other organic solvents have certain effect on pe. If the organic solvent is infiltrated into the polyethylene, the swelling will occur, and its physical properties will be decreased. Its pressure resistance and temperature resistance are poor.

- Q: Can ductile iron pipes be repaired if they get damaged?

- Yes, ductile iron pipes can be repaired if they get damaged. The repair process involves identifying the damaged portion of the pipe and assessing the severity of the damage. If the damage is minor, it can be repaired using various techniques such as welding or epoxy lining. For more extensive damage, sections of the pipe may need to be replaced. Pipe repair professionals have the expertise and equipment to identify and fix damaged ductile iron pipes, ensuring their continued functionality and longevity.

Send your message to us

Ductile Iron Pipe For Water Project with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords