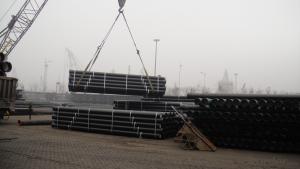

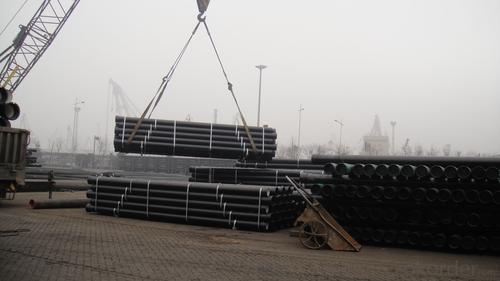

Ductile Iron Pipe For Water Project On Sale From China with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

Product Description:

Place of Origin: China (Mainland)

Model Number: T type / K type / Flange type

Length: 6M/NEGOTIATED

Standard: ISO2531 and EN545

Application: Potable/Sewage Water

Diameter: DN80~DN1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: STANDARD

Pull Strength: 420 Yield (≥ MPa): 300

Material: Cast Iron

Type: Ductile Iron Pipes

Certification: ISO2531 and EN545

Specification: DN80~DN1600

Outer Diameter: 80-1600

Thickness: standard

Usage: water pipe Packaging & Delivery

Packaging Details: DN80~DN300 are bundled with steel belts, others are in bulk condition.

Specification& Payment terms

Internal lining: Pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating: Pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing: Pipes from DN100 to DN300 be bundled with steel belts, others are in bulk.

Payment term: L/C, T/T.

Packing: In bulk vessel or in container.

- Q: What is the expected joint tightness for ductile iron pipes?

- Ductile iron pipes are renowned for their exceptional strength and durability, which grants them remarkable resistance against leaks and joint failures. Consequently, the joints in these pipes are meticulously designed to establish a secure and tight connection, effectively minimizing any potential water or fluid loss. In the realm of ductile iron pipes, a variety of joint types are commonly employed. These encompass mechanical joints, restrained joints, and push-on joints. Each of these joint types is uniquely crafted to deliver a reliable seal, effectively averting any leakage. Mechanical joints rely on a combination of a mechanical gland and rubber gaskets to forge an airtight seal. The assembly of these joints necessitates a specific level of torque to ensure proper compression and sealing. On the other hand, restrained joints are specifically tailored to withstand external forces, such as soil movement or pressure, while simultaneously preserving their tightness. To achieve this, these joints often incorporate a mechanical restraint system, such as a key-locking mechanism, thereby preventing joint separation. Meanwhile, push-on joints represent the most straightforward option to install, as they rely on a compressed rubber gasket that effectively seals the pipes when pushed together. These joints are most commonly employed in smaller diameter pipes, where external forces exerted on them are minimal. All in all, ductile iron pipes are expected to exhibit a high level of joint tightness, ensuring consistent and leak-free performance across a wide array of applications, including water distribution, wastewater systems, and industrial piping networks.

- Q: Ductile iron pipe in the direction of it?

- The utility model is mainly used for conveying water, and is an ideal choice for tap water pipes.

- Q: Can ductile iron pipes be used for trench crossings?

- Yes, ductile iron pipes can be used for trench crossings. Ductile iron pipes are known for their high strength and durability, making them suitable for a wide range of applications including trench crossings. They have the ability to withstand heavy loads and external pressures, making them an ideal choice for underground installations. Additionally, ductile iron pipes have excellent corrosion resistance properties, ensuring their longevity and reliability in trench crossing scenarios.

- Q: What are the advantages of using ductile iron pipes?

- There are several advantages of using ductile iron pipes in various applications. Firstly, ductile iron pipes have a high strength-to-weight ratio, making them a cost-effective choice for transporting fluids or gases. They can withstand high internal and external pressures, ensuring reliable and efficient transportation of materials. Secondly, ductile iron pipes have excellent corrosion resistance. They are resistant to rust and other forms of corrosion, which extends their lifespan and reduces maintenance costs. This makes them suitable for underground and underwater applications where corrosive elements are present. Additionally, ductile iron pipes have superior ductility, meaning they can withstand heavy external loads and impacts without cracking or breaking. This makes them less susceptible to damage during installation or when exposed to harsh environmental conditions. Moreover, ductile iron pipes have excellent flow characteristics. Their smooth inner surface minimizes friction and pressure losses, resulting in efficient fluid flow and reduced pumping costs. This is especially advantageous in applications where high flow rates or long-distance transportation is required. Furthermore, ductile iron pipes are environmentally friendly. They are made from recycled materials and can be recycled themselves, reducing the demand for raw materials and minimizing environmental impact. Additionally, their long service life minimizes the need for frequent replacements, further reducing waste generation. Lastly, ductile iron pipes have versatile installation options. They can be installed using various techniques such as trenchless methods, which minimize disruption to the surrounding environment and reduce installation costs. Their adaptability and ease of installation make them a preferred choice for various construction projects. Overall, the advantages of using ductile iron pipes include their high strength, corrosion resistance, ductility, flow characteristics, environmental friendliness, and versatile installation options. These factors make them a reliable and cost-effective choice for numerous applications in various industries.

- Q: How are ductile iron pipes manufactured?

- Ductile iron pipes are manufactured through a process called centrifugal casting. In this process, molten iron is poured into a spinning mold, which creates a centrifugal force. This force helps to distribute the molten iron evenly along the mold's inner surface, resulting in a dense and uniform pipe wall thickness. After cooling and solidification, the pipe is removed from the mold, tested for quality, and then coated with a protective layer to enhance its durability and resistance to corrosion.

- Q: Can ductile iron pipe be used for underground storage tank systems?

- Certainly, underground storage tank systems can utilize ductile iron pipe. Renowned for its robustness and potency, ductile iron pipe proves itself adaptable for diverse purposes, including underground storage tanks. Its exceptional tensile strength and immunity to corrosion render it a superb selection for confining and conveying liquids or gases in subterranean settings. Furthermore, ductile iron pipe exhibits remarkable resistance to external pressures and endures substantial burdens, establishing it as a dependable choice for underground storage tank systems.

- Q: Are ductile iron pipes resistant to hydrogen sulfide corrosion?

- Yes, ductile iron pipes are resistant to hydrogen sulfide corrosion due to their high resistance to chemical corrosion and their protective inner lining that prevents contact between the pipe material and the corrosive elements.

- Q: How are ductile iron pipes tested for hydrostatic pressure?

- Ductile iron pipes are tested for hydrostatic pressure through a process called hydrostatic testing. This involves filling the pipes with water and pressurizing them to a specific level, usually higher than their intended operating pressure. The pipes are then monitored for any leaks or excessive deformation under the applied pressure. This test ensures the strength and integrity of the ductile iron pipes before they are put into service.

- Q: How does ductile iron pipe perform in areas with high seismic activity?

- Ductile iron pipe is known for its exceptional strength and durability, which makes it well-suited for areas with high seismic activity. Seismic events, such as earthquakes, can subject pipelines to significant stress and strain, causing them to rupture or fail. However, ductile iron pipe has the ability to withstand these dynamic forces due to its unique material properties. One of the key advantages of ductile iron pipe in seismic areas is its superior flexibility. Unlike rigid materials such as cast iron or steel, ductile iron has a higher degree of elasticity, allowing it to deform and absorb energy during seismic events. This flexibility helps to dissipate the seismic forces, reducing the risk of pipe failure and minimizing damage to the overall pipeline system. Moreover, ductile iron pipe is manufactured with a high level of ductility, meaning it can undergo considerable deformation without fracturing. This property is crucial in seismic zones as it enables the pipe to withstand ground movements and seismic waves without compromising its structural integrity. The ability of ductile iron to absorb and redistribute stress also helps to prevent localized failures, ensuring the overall stability and reliability of the pipeline system. Additionally, ductile iron pipe is highly resistant to corrosion, which is especially important in high seismic areas where the integrity of the pipe may be compromised by ground movement and subsequent water leaks. The corrosion resistance of ductile iron ensures the longevity and reliability of the pipeline system, reducing the risk of leaks or failures during seismic events. In conclusion, ductile iron pipe performs exceptionally well in areas with high seismic activity due to its superior flexibility, high ductility, and corrosion resistance. These properties allow the pipe to withstand the dynamic forces generated during seismic events, providing a reliable and long-lasting solution for transporting fluids and ensuring the safety of communities in earthquake-prone regions.

- Q: What is the typical lifespan of ductile iron pipes?

- The lifespan of ductile iron pipes can differ based on multiple factors, including pipe quality, environmental conditions, and maintenance practices. On average, these pipes typically last approximately 75 to 100 years. This longevity establishes them as a sturdy and enduring choice for water and sewage transport systems. Through correct installation and consistent upkeep, these pipes can endure corrosion, pressure, and other external elements, guaranteeing their durability and dependability. Furthermore, advancements in coatings and linings have extended the lifespan of ductile iron pipes, making them an exceptional option for infrastructure projects.

Send your message to us

Ductile Iron Pipe For Water Project On Sale From China with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords