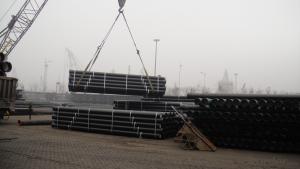

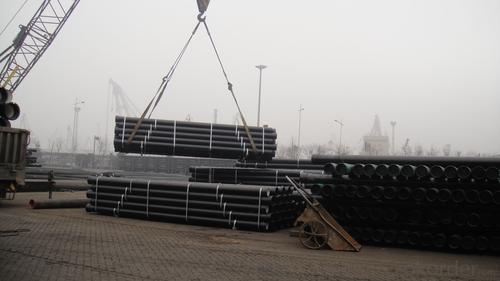

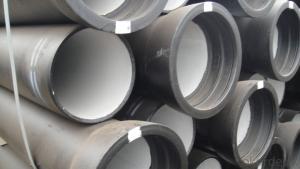

Ductile Iron Pipe For Water Project Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: What is the composition of ductile iron pipes?

- Ductile iron pipes are primarily composed of iron, along with small amounts of carbon, silicon, and other alloying elements. The iron content typically ranges from 90% to 94%, while carbon content is usually around 3% to 4%. Silicon is added in the range of 1.5% to 3%, which helps enhance the ductility and strength of the iron. Other alloying elements such as manganese, sulfur, and phosphorus may also be present in smaller quantities. The composition of ductile iron pipes is carefully engineered to achieve specific properties. The addition of carbon and silicon improves the hardness and strength of the iron, making it more suitable for demanding applications. The presence of these alloying elements also contributes to the ductility of the pipes, allowing them to be easily bent and molded without breaking. Overall, the composition of ductile iron pipes is designed to provide a balance between strength, ductility, and resistance to corrosion. This makes them ideal for use in water and sewage systems, where they can withstand high pressure, handle heavy loads, and resist the corrosive effects of water and other chemicals.

- Q: Are ductile iron pipes suitable for installation in areas with high soil compaction and traffic loads?

- Yes, ductile iron pipes are suitable for installation in areas with high soil compaction and traffic loads. Ductile iron pipes have high strength and durability, making them capable of withstanding heavy loads and compression from soil compaction. They offer excellent resistance to external forces and have a long lifespan, making them a reliable choice for such conditions.

- Q: Can ductile iron pipes be used for underground slurry pipelines?

- Yes, ductile iron pipes can be used for underground slurry pipelines. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them suitable for a variety of applications including underground slurry pipelines. They provide a reliable and cost-effective solution for transporting slurry, which is a mixture of solids and liquids, over long distances. The inherent toughness and flexibility of ductile iron pipes allow them to withstand the abrasive nature of slurry and the external loads associated with underground installation. Additionally, ductile iron pipes can be easily joined using various methods, ensuring a secure and leak-free pipeline system. However, it is important to consider the specific properties of the slurry being transported and consult with experts to determine the appropriate pipe specifications and design considerations for the underground slurry pipeline.

- Q: Does the cast iron pipe need separate corrosion protection?

- Ductile iron is characterized by its ease of decay and deformation, so if it is not a particular requirement, there is no need to do it alone

- Q: What is the ductile cast iron pipe

- Cast iron pipe is called a coiled pipe, one is the mouth, and the other is the flange. It is often used in the joint of the cast iron pipe valve, and is often used in conjunction with the second pipe (plug pipe coil)

- Q: What is the disadvantage of nodular cast iron in excess of silicon?

- Excessive silicon control results in the formation of nodular graphite in large cross section ductile iron and reduces the mechanical properties of castings.

- Q: What are the different pressure ratings available for ductile iron pipe?

- Ductile iron pipe, known for its strength, durability, and resistance to corrosion, finds widespread use in various applications. The pressure ratings of this type of pipe depend on factors like diameter and wall thickness. Typically, ductile iron pipe offers pressure ratings ranging from 150 psi to 350 psi. For pipes with smaller diameters, usually measuring between 3 inches and 24 inches, commonly available pressure ratings include 150 psi, 200 psi, and 250 psi. These ratings suit a broad range of applications, including water distribution systems, sewer lines, and industrial piping. For larger diameter pipes, typically ranging from 30 inches to 64 inches, the usual pressure ratings are 150 psi, 200 psi, 250 psi, and 350 psi. These higher ratings are necessary for transporting larger volumes of water or other fluids across longer distances. It is worth noting that the pressure ratings of ductile iron pipe adhere to industry standards and guidelines. These standards ensure that the pipe can safely withstand both internal pressure and external loads during operation. When choosing the appropriate pressure rating for ductile iron pipe, it is vital to consider factors such as the specific application, flow rates, and expected operating conditions. Seeking advice from industry experts and adhering to local codes and regulations is crucial to ensure the correct selection and installation of ductile iron pipe for a particular project.

- Q: How can the steel plastic composite pipe be connected with the cast iron pipe?

- The hoop has the advantages of beautiful appearance, convenient operation, strong clamping force, good sealing performance, etc.. Mainly used for connecting and fastening vehicle, ship, diesel engine, gasoline engine, machine tools, fire, and other machinery and equipment, chemical equipment general nylon hose, plastic hose, hose cloth, water interface and seal etc..

- Q: What is the maximum allowable deflection for ductile iron pipes?

- The maximum allowable deflection for ductile iron pipes is typically specified by industry standards and guidelines, such as those provided by the American Water Works Association (AWWA) and the Ductile Iron Pipe Research Association (DIPRA). These standards specify the maximum allowable deflection as a percentage of the pipe's outside diameter. According to AWWA C150/A21.50 and DIPRA's Technical Bulletin No. 10, the maximum allowable deflection for ductile iron pipes can vary depending on factors such as pipe size, wall thickness, and soil conditions. However, a common rule of thumb is that the maximum allowable deflection should not exceed 3% of the pipe's outside diameter. It is important to note that exceeding the maximum allowable deflection can result in potential structural issues and reduced performance of the ductile iron pipe. Therefore, it is crucial to adhere to the industry standards and guidelines to ensure the proper installation and functioning of ductile iron pipes.

- Q: How do ductile iron pipes perform in high-pressure applications?

- Ductile iron pipes are highly renowned for their exceptional strength and durability, making them incredibly suitable for applications with high pressure. These pipes are specifically designed to endure immense internal and external pressures, making them well-suited for both underground and above-ground installations where high-pressure conditions are anticipated. One of the primary advantages of utilizing ductile iron pipes in high-pressure applications lies in their capacity to resist cracking or bursting. The material's inherent ductility enables it to absorb and distribute pressure evenly, significantly reducing the risk of failure under high-pressure circumstances. Consequently, ductile iron pipes are a dependable choice for water supply systems, oil and gas pipelines, and other demanding applications subject to substantial pressure. Moreover, ductile iron pipes exhibit outstanding corrosion resistance properties, further enhancing their performance in high-pressure environments. These pipes are typically coated with a protective layer, such as cement mortar or epoxy, which serves as a barrier against corrosion. By preventing the formation of rust or scale inside the pipe, this protective coating ensures smooth flow and upholds structural integrity even under high-pressure conditions. Furthermore, ductile iron pipes possess a remarkable tolerance for external loads, including soil pressure, traffic loads, and various other forces. This exceptional strength enables them to withstand the additional stress often encountered in high-pressure applications, guaranteeing the long-term reliability and performance of the pipe system. In conclusion, ductile iron pipes offer exceptional performance in high-pressure applications. Their strength, durability, corrosion resistance, and ability to withstand external loads make them a reliable choice for a wide range of industries and infrastructure projects where high-pressure conditions are a significant concern.

Send your message to us

Ductile Iron Pipe For Water Project Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords