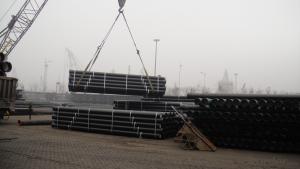

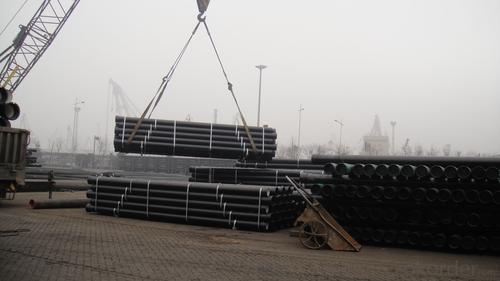

Ductile Iron Pipe For Water Project On Sale From China with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Are ductile iron pipes susceptible to external loading or pressure?

- Ductile iron pipes, just like any other material, are susceptible to external loading or pressure. They possess a certain level of strength and tolerance to endure external forces. However, excessive external loading or pressure can result in the deformation or failure of these pipes. To avoid any harm caused by external loading, it is crucial to ensure proper installation and support of ductile iron pipes. Furthermore, the design and engineering of the pipeline system should take into account the expected external loading and pressure to guarantee the pipes' effectiveness in handling the anticipated conditions. Regular inspections and maintenance play a vital role in detecting and resolving issues associated with external loading or pressure that may arise over time.

- Q: What is the expected buoyancy of ductile iron pipes?

- The expected buoyancy of ductile iron pipes can vary depending on several factors such as the diameter, wall thickness, and the specific gravity of the fluid being transported. However, in general, ductile iron pipes are known for their relatively low buoyancy compared to other materials like plastic or concrete. Due to their higher density and weight, ductile iron pipes tend to have a greater resistance to buoyancy forces. This makes them suitable for applications where buoyancy is a concern, such as water and wastewater transmission systems. The combination of their inherent strength and weight helps to keep the pipes grounded and prevents them from floating or rising to the surface. It is important to note that even though ductile iron pipes have lower buoyancy compared to other materials, they may still experience some level of buoyancy in certain scenarios, especially when the fluid being transported has a lower specific gravity. To mitigate this potential issue, additional measures such as anchoring or ballasting may be employed to ensure the stability and integrity of the pipeline system. Overall, while the expected buoyancy of ductile iron pipes is generally low, it is crucial to consider the specific conditions and requirements of the project to determine the most appropriate pipe material and design for optimal performance and safety.

- Q: Is nodular cast iron pipe filled with Yau Ma Tei?

- The main components of ductile iron pipes are carbon, silicon, manganese, sulfur, phosphorus and magnesium. Perform standard [span]GB/T13295-2003 ISO2531/2003

- Q: What is the expected thrust restraint method for ductile iron pipes?

- The expected thrust restraint method for ductile iron pipes is typically achieved through the use of thrust blocks or restraints, which are designed to counteract the forces generated by the fluid pressure within the pipeline. These blocks or restraints are typically made of concrete or other sturdy materials and are strategically placed at bends, tees, and other locations where changes in direction occur. They help to anchor the pipes and prevent them from moving or being displaced due to the thrust forces.

- Q: Comparison of ductile iron pipe and spiral steel pipe

- Can only be used for drainage pipe for comparison, other uses are not mentioned in the same breath.

- Q: Are ductile iron pipes available in different wall thicknesses?

- Yes, ductile iron pipes are available in different wall thicknesses to accommodate various applications and requirements.

- Q: Are ductile iron pipes suitable for sewer force mains?

- Yes, ductile iron pipes are suitable for sewer force mains. Ductile iron is a type of cast iron that has a higher level of strength and flexibility compared to traditional cast iron pipes. This makes it ideal for applications where the pipes need to withstand high pressure and heavy loads, such as sewer force mains. Ductile iron pipes have excellent resistance to corrosion and are highly durable, which is crucial for sewer systems that are exposed to various corrosive substances and harsh environments. They also have the ability to absorb vibrations and shocks, reducing the risk of pipe failures caused by external forces. Furthermore, ductile iron pipes are known for their long service life, often lasting for more than 100 years. This makes them a cost-effective choice for sewer force mains, as they require minimal maintenance and replacement over their lifetime. Overall, ductile iron pipes offer a reliable and durable solution for sewer force mains, providing the necessary strength, flexibility, and resistance to corrosion to ensure efficient and long-lasting sewer systems.

- Q: What is the external coating used in ductile iron pipes?

- The external coating commonly used in ductile iron pipes is a protective layer made of either cement mortar or polyethylene.

- Q: What are the advantages of using ductile iron pipes over other materials?

- Using ductile iron pipes instead of other materials offers several advantages. To begin with, ductile iron pipes have a higher level of strength and durability compared to materials like PVC, HDPE, or concrete pipes. They possess a high tensile strength, enabling them to withstand greater pressure and handle heavy loads without cracking or breaking. This makes them suitable for a range of applications, including water and sewage systems, as well as industrial pipelines. Additionally, ductile iron pipes exhibit excellent resistance to corrosion. They typically feature a protective coating, such as zinc or epoxy, which prevents the formation of rust and extends their lifespan. This makes them ideal for underground installations or areas with aggressive soil conditions or corrosive substances. Furthermore, ductile iron pipes offer flexibility. They can be manufactured in various lengths, diameters, and angles, allowing for easy installation and adaptation to different project requirements. Moreover, their flexibility enables them to withstand ground movements, such as settlement or seismic activities, without causing significant damage. Moreover, ductile iron pipes have a smooth internal surface, which reduces friction and enhances flow efficiency. This results in reduced energy consumption for pumping systems and lower maintenance costs. Additionally, the smooth surface minimizes the risk of deposits or clogs, ensuring a consistent and uninterrupted flow of fluids. Lastly, ductile iron pipes boast a long service life. With proper installation and maintenance, they can last for over 100 years. This longevity not only reduces the need for frequent replacements but also provides a sustainable and cost-effective solution for infrastructure projects. In conclusion, the utilization of ductile iron pipes offers numerous advantages over other materials. These include superior strength, corrosion resistance, flexibility, a smooth internal surface, and a long service life. These qualities make them a reliable choice for various applications, providing efficient and durable solutions for water, sewage, and industrial pipelines.

- Q: How does ductile iron pipe perform in extreme weather conditions?

- Ductile iron pipes are renowned for their exceptional performance in adverse weather conditions. These pipes demonstrate remarkable durability, resistance, and flexibility, making them suitable for enduring harsh weather such as extreme temperatures, heavy rainfall, snowfall, and even earthquakes. One of the notable characteristics of ductile iron is its capacity to withstand damage caused by freezing temperatures. Unlike other materials, ductile iron pipes possess a low coefficient of thermal expansion, enabling them to resist the expansion and contraction that occurs during freeze-thaw cycles without experiencing cracks or breaks. Consequently, these pipes remain intact and continue to function optimally even in extremely cold conditions. Furthermore, ductile iron pipes exhibit excellent resistance to corrosion, rendering them highly resilient to the corrosive effects of severe weather. They are shielded by a sturdy zinc coating, which acts as a barrier against rust and other forms of corrosion. This coating, in conjunction with the inherent strength of ductile iron, grants these pipes exceptional resistance to the corrosive effects of rain, snow, and moisture. Moreover, ductile iron pipes possess superior flexibility, allowing them to accommodate ground movement and seismic activity. In areas prone to earthquakes or soil shifting, these pipes can absorb stress and strain without fracturing, guaranteeing a continuous supply of water and sewage services even in the most challenging weather conditions. Overall, ductile iron pipes excel in extreme weather conditions due to their durability, resistance to freezing, corrosion, and flexibility. Their ability to withstand the elements ensures an uninterrupted supply of water and sewage systems, providing reliability and peace of mind to utility providers and communities, even in the most unforgiving environments.

Send your message to us

Ductile Iron Pipe For Water Project On Sale From China with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords