Ductile Iron Pipe EN598 DN250 Class K9

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

DI pipe fittings are manufactured according to ISO 2531 or BS EN545 or BS4772 FOR POTABLE WATER ,internal is cement lining or wet epoxy coating;External is zinc plus bitumen or wet epoxy coating. We also manufacture ductile iron fittings with fusion bonded epoxy both inside and outside. All the producets are sutible to water pipes fields.

We have passed ISO9001,ISO14001,OHSMS18001 certificate.

2,Main Features of the Ductile Iron Pipe:

1).Quality guarantee

• Chemical checking

• NDE after rough machining

• Mechanical testing after heat treatment

• Final NDE,dimension inspected

2).Quality document

• Full Q.A document as per client request

3).Packing and Shipping

• standard export package(carton/wooden case/pallet)

• accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

4).Service

• Drawing: we can translate your original drawing, offer best suggestion on design

• Quality: we have full set quality control system to guarantee the best quality.

• Inspection: inspect in house, all our products must be checked 3 times before packing

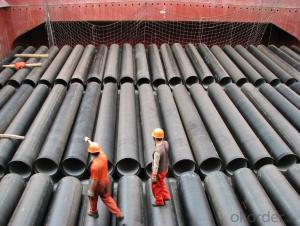

3,Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Surface Finishes: Bare, Oiled, Mill Varnish, Galv,FBE, FBE Dual, 3LPE, 3LPP, Coal Tar,Concrete Coating and Tape Wrap

End Finishes: Beveled, Square Cut, Threaded, hat

Additional Services: Internal Coating

Packaging: packed in bag, plastic bag, steel strip, steel wire,double wire, iron box, wooden box, tarpaulin, plastic sheeting

Inspection: MOODY SGS BV GL DNV ABS LIOYD’S

Test: X-ray, UT, magnetic particle,inspection,hydrostatic test.

Processing service: Beveling, Threading, Slotting, Cut-to length, Bends, Quench and Temper, Fabrication, Double-jointing and On-site assistance

Documentary: MTC, material certification,Origin certification, CI or PI,Test Report, export licence, handling order, B/L,insurance policy,shipping instructions, contract, packing list etc.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: What are the common pressure ratings for ductile iron pipes?

- Common pressure ratings for ductile iron pipes vary depending on the specific application and industry standards. However, the most commonly used pressure ratings for ductile iron pipes are Class 150, Class 200, Class 250, and Class 350. Class 150 ductile iron pipes are typically used for low-pressure applications, with a working pressure of up to 150 psi (pounds per square inch). These pipes are commonly used for water distribution systems, irrigation, and gravity flow sewer systems. Class 200 ductile iron pipes have a higher working pressure of up to 200 psi. These pipes are often used for applications that require a slightly higher pressure, such as industrial water supply, fire protection systems, and wastewater treatment plants. Class 250 ductile iron pipes have a working pressure of up to 250 psi. These pipes are suitable for more demanding applications, such as high-pressure water supply systems, power plants, and municipal water distribution networks. Class 350 ductile iron pipes have the highest working pressure rating, with a maximum pressure of up to 350 psi. These pipes are typically used for heavy-duty applications, such as industrial water supply, oil and gas pipelines, and large-scale water transportation projects. It's important to note that these pressure ratings are general guidelines and may vary depending on the specific manufacturer and product specifications. Consulting industry standards and guidelines, as well as working with qualified engineers and professionals, is essential to ensure the correct pressure rating is selected for a particular ductile iron pipe application.

- Q: Are ductile iron pipes suitable for railway crossings?

- Yes, ductile iron pipes can be suitable for railway crossings. Ductile iron is a strong and durable material that has been widely used in various applications, including water and sewage systems. Its high tensile strength and flexibility make it suitable for withstanding heavy loads and vibrations, which are common near railway crossings. Furthermore, ductile iron pipes have excellent resistance to corrosion, which is crucial in areas prone to moisture and exposure to different weather conditions. This resistance ensures the longevity of the pipes, reducing maintenance and replacement costs. Additionally, ductile iron pipes are known for their ease of installation and versatility. They can be easily connected with other types of pipes or fittings, allowing for a seamless integration into the overall railway crossing infrastructure. It is important to note that the suitability of ductile iron pipes for railway crossings also depends on various factors such as load requirements, soil conditions, and specific project specifications. Consulting with engineering professionals and adhering to industry standards and regulations is essential to ensure the appropriate selection and installation of ductile iron pipes for railway crossings.

- Q: What are the different pressure ratings available for ductile iron pipe?

- Ductile iron pipe, known for its strength, durability, and resistance to corrosion, finds widespread use in various applications. The pressure ratings of this type of pipe depend on factors like diameter and wall thickness. Typically, ductile iron pipe offers pressure ratings ranging from 150 psi to 350 psi. For pipes with smaller diameters, usually measuring between 3 inches and 24 inches, commonly available pressure ratings include 150 psi, 200 psi, and 250 psi. These ratings suit a broad range of applications, including water distribution systems, sewer lines, and industrial piping. For larger diameter pipes, typically ranging from 30 inches to 64 inches, the usual pressure ratings are 150 psi, 200 psi, 250 psi, and 350 psi. These higher ratings are necessary for transporting larger volumes of water or other fluids across longer distances. It is worth noting that the pressure ratings of ductile iron pipe adhere to industry standards and guidelines. These standards ensure that the pipe can safely withstand both internal pressure and external loads during operation. When choosing the appropriate pressure rating for ductile iron pipe, it is vital to consider factors such as the specific application, flow rates, and expected operating conditions. Seeking advice from industry experts and adhering to local codes and regulations is crucial to ensure the correct selection and installation of ductile iron pipe for a particular project.

- Q: Are ductile iron pipes resistant to biological growth?

- Yes, ductile iron pipes are generally resistant to biological growth. The smooth interior surface of ductile iron pipes prevents the buildup of biofilm and inhibits the growth of bacteria and other organisms. Additionally, the material itself is not conducive to the growth of biological contaminants, making ductile iron pipes a reliable choice for water and wastewater applications.

- Q: What are the interface forms of ductile iron pipes? The best drawings are available. Thank you

- Because of this interface and the corresponding T sealing aprons can withstand greater deflection angle and greater tolerances, especially suitable for unstable formations and corners.

- Q: Can ductile iron pipes be used for river crossings?

- Yes, ductile iron pipes can be used for river crossings. Ductile iron is a strong and durable material that can withstand the stresses and pressures of being installed underground and crossing rivers. It is commonly used in water and sewage systems, including river crossings, due to its resistance to corrosion and its ability to handle high water pressure.

- Q: What is the process of fusion bonding for ductile iron pipes?

- Fusion bonding for ductile iron pipes is a process that involves heating the pipes to a specific temperature and then applying pressure to fuse the ends of two pipes together. This creates a strong and durable bond between the pipes, ensuring a leak-proof connection. The fusion bonding process is commonly used in the construction and maintenance of underground water and sewer systems.

- Q: How to properly maintain FRP pipes

- It has excellent corrosion resistanceDo not use cathodic protection and other anti-corrosion measures to produce two contamination of water and other media. Long service life of products.

- Q: Are ductile iron pipes suitable for installation in areas with high groundwater contamination and soil erosion?

- Areas with high groundwater contamination and soil erosion are typically well-suited for the installation of ductile iron pipes. This is due to the fact that ductile iron pipes are renowned for their durability, strength, and corrosion resistance. They exhibit exceptional resistance to acidic and alkaline soils, rendering them appropriate for regions with elevated levels of groundwater contamination. Moreover, the robust construction of ductile iron pipes grants them a formidable resistance to soil erosion. They are engineered to endure a range of external forces, including the pressure exerted by the surrounding soil and the potential movement resulting from erosion. Consequently, they are a dependable choice for installation in areas prone to soil erosion. Nonetheless, it is vital to acknowledge that while ductile iron pipes can withstand high levels of groundwater contamination and soil erosion, the implementation of proper installation techniques and maintenance practices is crucial to ensure their longevity and optimal performance. Regular inspections, meticulous backfilling, and the application of suitable protective coatings should be employed to maximize the lifespan of the pipes. To sum up, ductile iron pipes are generally well-suited for installation in areas characterized by high groundwater contamination and soil erosion. Their durability, strength, resistance to corrosion, and high resistance to soil erosion establish them as a reliable choice for such environments. However, adhering to proper installation and maintenance practices is imperative to guarantee their longevity and optimal performance.

- Q: What pipe can be used to replace the cast iron pipe in the water supply? Thank you

- According to the casting method, it is divided into continuous cast iron pipe and centrifugal cast iron pipe, in which the centrifugal cast iron pipe is divided into sand mould and metal type two kinds. Divided into gray cast iron pipe and nodular cast iron pipe according to different material. According to the interface form, it is divided into flexible interface, flange interface, self anchored interface, rigid interface and so on. Among them, the flexible iron pipes rubber sealing ring; flange interface cast iron pipe flange fixed in the rubber pad, the flange gasket sealing; rigid interface cast iron pipe socket is large, straight pipe is inserted, sealed with cement, this technology has been basically eliminated.

Send your message to us

Ductile Iron Pipe EN598 DN250 Class K9

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords