Ductile Iron Pipe EN545/EN598 DN80-DN500 K9

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

DI pipe fittings are manufactured according to ISO 2531 or BS EN545 or BS4772 FOR POTABLE WATER ,internal is cement lining or wet epoxy coating;External is zinc plus bitumen or wet epoxy coating. We also manufacture ductile iron fittings with fusion bonded epoxy both inside and outside. All the producets are sutible to water pipes fields.We have passed ISO9001,ISO14001,OHSMS18001 certificate.

2,Main Features of the Ductile Iron Pipe:

1).Quality guarantee

• Chemical checking

• NDE after rough machining

• Mechanical testing after heat treatment

• Final NDE,dimension inspected

2).Quality document

• Full Q.A document as per client request

3).Packing and Shipping

• standard export package(carton/wooden case/pallet)

• accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

4)Inspection

• In-house Foundry

• Third party inspection available upon requirement

5) Our goal

• To be your preferred partner

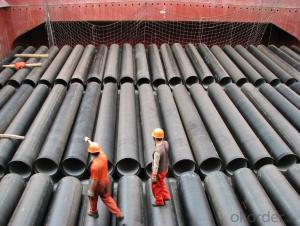

3,Ductile Iron Pipe Images:

4. Ductile Iron Pipe Specification:

Standard: API SPEC 5L 44th eidtion,ASTM A252-98(2007)

Grade: A53 Grades A/B, ASTM A106 Grades B/C,ASTM A179

AWWA, C200, ASTM A139, ASTM A120, API 5L Grade B

X42, X52, X56, X60, X65, X70, X80, X100

Weld Alternatives: LSAW

OD size range: 6.4~44.5mm

Wall thickness: 406.4~1422mm

Length: 3 - 12 m according to requirment

Note: Other grade can also be provided after consulting. Special design are available

for coal slurry conveyance LSAW line tube -- Service

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Are ductile iron pipes suitable for potable water distribution systems?

- Yes, ductile iron pipes are suitable for potable water distribution systems. Ductile iron is a type of cast iron that is known for its high strength and durability, making it an excellent choice for conveying drinking water. These pipes are resistant to corrosion, which is essential for maintaining the quality and safety of potable water. Additionally, ductile iron pipes have a smooth interior surface, which helps to minimize the accumulation of sediments and biofilms that can affect water quality. They also have the ability to withstand high pressure and temperature changes, making them suitable for various potable water distribution systems. Overall, ductile iron pipes are a reliable and widely used option for ensuring the delivery of safe and clean drinking water to communities.

- Q: Ductile iron pipe converter, steel transition DN100 turn 100, what is the specific accessories name? Can you supply photos?

- Strong toughness: the pipe can be stretched to 5 times the original length without fracture, which is suitable for uneven geological conditions without affecting its link performance. In the case of a breach, there is no extension of the mouth due to the breach.

- Q: Can ductile iron pipes be used for trench crossings?

- Yes, ductile iron pipes can be used for trench crossings. Ductile iron pipes are known for their high strength and durability, making them suitable for a wide range of applications including trench crossings. They have the ability to withstand heavy loads and external pressures, making them an ideal choice for underground installations. Additionally, ductile iron pipes have excellent corrosion resistance properties, ensuring their longevity and reliability in trench crossing scenarios.

- Q: How do ductile iron pipes handle cyclic loading in offshore applications?

- Ductile iron pipes are known for their exceptional strength and durability, making them a suitable choice for various applications, including offshore use. When it comes to handling cyclic loading in offshore environments, ductile iron pipes have several characteristics that contribute to their performance. Firstly, ductile iron pipes have a high resistance to fatigue failure. Fatigue failure occurs when a material experiences repeated cycles of stress, which can cause cracks to initiate and propagate over time. Ductile iron pipes are designed to withstand cyclic loading without compromising their structural integrity, thanks to their inherent ductility and ability to absorb and distribute stress effectively. Additionally, ductile iron pipes possess excellent impact resistance. Offshore environments are prone to dynamic and unpredictable forces, such as waves and currents, which can exert sudden and high impact loads on the pipes. The high impact resistance of ductile iron allows it to withstand these forces without deformation or fracture, ensuring the pipes remain intact and functional. Moreover, ductile iron pipes have a unique microstructure that enables them to resist corrosion. Offshore applications expose pipes to harsh environmental conditions, including saltwater, which can accelerate the corrosion process. However, the protective graphite matrix in ductile iron pipes acts as a barrier, preventing corrosive agents from reaching the underlying metal and significantly extending the pipes' service life. Furthermore, ductile iron pipes have a high load-carrying capacity. In offshore applications, pipes often need to support heavy loads, such as those from equipment, structures, or seabed settlements. Ductile iron's superior strength allows it to bear these loads effectively, maintaining the structural integrity and stability of the system. Lastly, ductile iron pipes offer ease of installation and maintenance. Their lightweight nature makes them easier to handle and transport during offshore operations. Additionally, their corrosion resistance minimizes the need for frequent maintenance, reducing downtime and costs associated with repairs and replacements. In conclusion, ductile iron pipes exhibit excellent performance in handling cyclic loading in offshore applications. Their resistance to fatigue failure, impact resistance, corrosion resistance, high load-carrying capacity, and ease of installation and maintenance make them a reliable and efficient choice for offshore environments.

- Q: Ductile iron gears are generally treated without heat treatment

- Heat treatment must be necessary, generally annealed first to machine, after quenching or nitriding treatment

- Q: Can ductile iron pipe be used for road and highway crossings?

- Yes, ductile iron pipe can be used for road and highway crossings. Ductile iron pipes are known for their high strength, durability, and flexibility, making them suitable for various applications, including road and highway crossings. They can withstand heavy loads and provide excellent resistance to external forces, making them a reliable choice for underground installations in transportation infrastructure.

- Q: How many meters does the cast iron water supply pipe dn150,1 tons?

- Reciprocating centrifuge hydraulic device, the pressure was 9.65 x 105Pa. the speed through the overflow valve, cable and cooling water hose is generally fixed on the centrifuge and the machine next to the post, the other end is connected to the shell, random moving together. The production standard of centrifuges is usually fixed. If we want to produce several specifications of pipes on a centrifuge, we need to replace the fan-shaped packages, the hot metal flow plants and the support roller racks.

- Q: Can ductile iron pipes be used for wastewater reuse projects?

- Ductile iron pipes are suitable for wastewater reuse projects due to their various properties. Firstly, they possess high strength and durability, enabling them to withstand the pressure and load requirements of wastewater systems. Additionally, they exhibit outstanding corrosion resistance, a crucial factor in wastewater applications where the presence of chemicals and corrosive substances is common. Moreover, the smooth internal lining of ductile iron pipes reduces friction and enhances the flow of wastewater. This is essential for efficient transportation and distribution of wastewater in reuse projects. Furthermore, ductile iron pipes are renowned for their ease of installation and maintenance. They can be effortlessly connected using various joint options, facilitating quick and efficient installation. Additionally, their long service life reduces the necessity for frequent replacements and minimizes maintenance costs. In conclusion, the properties of ductile iron pipes make them a suitable option for wastewater reuse projects, providing strength, durability, corrosion resistance, smooth flow, and ease of installation and maintenance.

- Q: What is the maximum allowable deflection for ductile iron pipes?

- Industry standards and guidelines, like those from the American Water Works Association (AWWA) and the Ductile Iron Pipe Research Association (DIPRA), typically specify the maximum allowable deflection for ductile iron pipes. These standards state that the maximum allowable deflection should be a certain percentage of the pipe's outside diameter. AWWA C150/A21.50 and DIPRA's Technical Bulletin No. 10 explain that the maximum allowable deflection for ductile iron pipes can vary depending on factors such as pipe size, wall thickness, and soil conditions. However, a general rule is that the maximum allowable deflection should not exceed 3% of the pipe's outside diameter. It is important to keep in mind that going beyond the maximum allowable deflection can lead to potential structural problems and reduced performance of the ductile iron pipe. Therefore, it is crucial to follow the industry standards and guidelines to ensure the proper installation and functioning of ductile iron pipes.

- Q: What are the advantages of using ductile iron pipes over other materials?

- There are several advantages of using ductile iron pipes over other materials. Firstly, ductile iron pipes have a high tensile strength, which makes them more resistant to pressure and external forces, reducing the risk of cracks or leaks. Secondly, ductile iron pipes have a longer lifespan compared to other materials, as they are highly durable and resistant to corrosion. Additionally, ductile iron pipes have a smooth internal surface, promoting efficient water flow and minimizing the risk of blockages. Lastly, ductile iron pipes are relatively cost-effective and easy to install, making them a preferred choice for various applications in water distribution, sewer systems, and industrial settings.

Send your message to us

Ductile Iron Pipe EN545/EN598 DN80-DN500 K9

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords