Ductile Iron Pipe Class L10 Low Price Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 299 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market, such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

·High yield strength

·High tensile Strength

·High corrosion resistance

·Pressure Resistence

·Anti-corrosion

·Installation is convenient

·Satisfy the highest hygienic standards

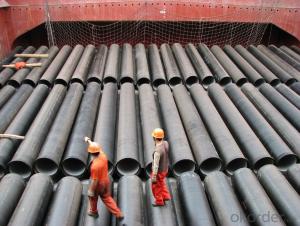

3,Ductile Iron Pipe Images:

4.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Can ductile iron pipes be used in culvert or storm sewer applications?

- Yes, ductile iron pipes can be used in culvert or storm sewer applications. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them suitable for handling the high demands and harsh conditions typically found in culverts and storm sewers.

- Q: How does ductile iron pipe perform in areas with high soil erosion?

- Ductile iron pipe is renowned for its remarkable strength and durability, rendering it a dependable option for regions experiencing extensive soil erosion. With its distinctive composition, including graphite nodules, it possesses the capacity to be both pliable and resistant to fractures or cracks, even in demanding environments. Consequently, ductile iron pipe is highly capable of enduring the impact of soil erosion. In regions with high soil erosion, the surface of the pipe can potentially be scraped by soil particles, leading to abrasions or damage. However, ductile iron pipe's substantial wall thickness and corrosion-resistant coating effectively serve as a barrier against these abrasive forces. Consequently, even in regions with considerable soil erosion, ductile iron pipe can maintain its structural integrity and functionality. Additionally, the ability of ductile iron pipe to resist corrosion further augments its performance in areas with high soil erosion. Soil erosion frequently results in increased moisture content, which can expedite the corrosion process for certain materials. Nonetheless, ductile iron pipe's protective coating, typically composed of zinc or epoxy, acts as a shield against corrosion, ensuring prolonged performance and reliability. To summarize, ductile iron pipe exhibits exceptional performance in regions with high soil erosion due to its strength, flexibility, and resistance to fractures or cracks. Its substantial wall thickness and corrosion-resistant coating make it highly durable against abrasive forces and corrosion, enabling it to withstand the challenges posed by soil erosion. Consequently, ductile iron pipe is a dependable choice for infrastructure projects in these areas, offering long-lasting and efficient water and wastewater transportation systems.

- Q: What is ductile iron pipe?

- Ductile iron pipe is a kind of cast iron pipe. In quality, the spheroidization of cast iron pipes is controlled to be 1-3 (spheroidization rate 80%), so the mechanical properties of the material have been better improved, with the nature of iron and the properties of steel. Ductile cast iron pipe after annealing, the microstructure is ferrite and pearlite, good mechanical properties, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc..

- Q: What is the expected thrust restraint method for ductile iron pipes?

- Typically, to achieve the expected thrust restraint for ductile iron pipes, mechanical joint restraints are employed. These restraints are designed to counteract the axial forces or thrust caused by the fluid pressure within the pipe. Thrust blocks, tie rods, and harness restraints are the most commonly used types of mechanical joint restraints for ductile iron pipes. Thrust blocks are concrete structures strategically placed around the pipe joints to resist the thrust forces. They are typically constructed at bends, tees, and other directional changes to prevent pipe movement. Tie rods, on the other hand, are another frequently used method of thrust restraint. These involve steel rods that are anchored to the pipe and securely fastened to an immovable structure to counter the thrust forces. Harness restraints, however, are constituted by a series of steel rods or cables that encircle the pipe and are anchored to the ground on both sides. These restraints effectively distribute the axial forces along the pipe's length, preventing movement and ensuring stability. The choice of a specific thrust restraint method for ductile iron pipes may vary depending on various factors such as pipe diameter, fluid pressure, soil conditions, and local regulations. It is vital to consult industry standards, engineering guidelines, and local authorities to determine the appropriate thrust restraint method for a particular application.

- Q: How do ductile iron pipes handle cyclic loading in offshore applications?

- Ductile iron pipes are known for their exceptional strength and durability, making them a suitable choice for various applications, including offshore use. When it comes to handling cyclic loading in offshore environments, ductile iron pipes have several characteristics that contribute to their performance. Firstly, ductile iron pipes have a high resistance to fatigue failure. Fatigue failure occurs when a material experiences repeated cycles of stress, which can cause cracks to initiate and propagate over time. Ductile iron pipes are designed to withstand cyclic loading without compromising their structural integrity, thanks to their inherent ductility and ability to absorb and distribute stress effectively. Additionally, ductile iron pipes possess excellent impact resistance. Offshore environments are prone to dynamic and unpredictable forces, such as waves and currents, which can exert sudden and high impact loads on the pipes. The high impact resistance of ductile iron allows it to withstand these forces without deformation or fracture, ensuring the pipes remain intact and functional. Moreover, ductile iron pipes have a unique microstructure that enables them to resist corrosion. Offshore applications expose pipes to harsh environmental conditions, including saltwater, which can accelerate the corrosion process. However, the protective graphite matrix in ductile iron pipes acts as a barrier, preventing corrosive agents from reaching the underlying metal and significantly extending the pipes' service life. Furthermore, ductile iron pipes have a high load-carrying capacity. In offshore applications, pipes often need to support heavy loads, such as those from equipment, structures, or seabed settlements. Ductile iron's superior strength allows it to bear these loads effectively, maintaining the structural integrity and stability of the system. Lastly, ductile iron pipes offer ease of installation and maintenance. Their lightweight nature makes them easier to handle and transport during offshore operations. Additionally, their corrosion resistance minimizes the need for frequent maintenance, reducing downtime and costs associated with repairs and replacements. In conclusion, ductile iron pipes exhibit excellent performance in handling cyclic loading in offshore applications. Their resistance to fatigue failure, impact resistance, corrosion resistance, high load-carrying capacity, and ease of installation and maintenance make them a reliable and efficient choice for offshore environments.

- Q: What are the different pressure ratings available for ductile iron pipe?

- The pressure ratings available for ductile iron pipe typically range from 150 psi to 350 psi, depending on the size and application of the pipe.

- Q: Are ductile iron pipes suitable for acidic or alkaline environments?

- Yes, ductile iron pipes are suitable for both acidic and alkaline environments. They have excellent resistance to corrosion, making them a reliable choice for transporting fluids in a wide range of pH levels.

- Q: How are ductile iron pipes tested for quality assurance?

- Ductile iron pipes undergo various testing procedures to ensure their quality and meet industry standards. These quality assurance tests are conducted on both raw materials and finished products to ensure the durability, strength, and overall reliability of ductile iron pipes. One of the initial tests is the chemical analysis of the raw materials used in manufacturing the pipes. This analysis ensures that the composition of the iron, carbon, and other elements is within the specified range, as different compositions can affect the pipe's strength and corrosion resistance. Next, mechanical tests are performed to evaluate the strength and ductility of the pipes. Tensile tests are conducted to determine the ultimate tensile strength, yield strength, and elongation properties of the pipe. This helps in assessing the pipe's ability to withstand external pressure or bending forces. Additionally, impact tests are performed to evaluate the pipe's resistance to sudden loading or impact. This test measures the energy absorbed by the pipe when subjected to a high impact force, ensuring that it can withstand potential accidental impacts during installation or operation. Another critical test is the hydrostatic pressure test, which checks the pipes' ability to withstand internal pressure. In this test, the pipes are filled with water and subjected to a specified pressure for a specific duration. This ensures that the pipes can withstand the expected operating pressure without any leakage or failure. Furthermore, dimensional and visual inspections are conducted to ensure that the pipes meet the required specifications. These inspections include checking the pipe's outer diameter, length, wall thickness, and overall appearance for any defects, such as cracks, voids, or irregularities. Lastly, corrosion resistance tests are performed to assess the pipe's ability to resist corrosion when exposed to different environments or fluids. This helps in determining the expected lifespan of the pipes and their suitability for various applications. Overall, these quality assurance tests play a crucial role in ensuring that ductile iron pipes meet the required standards and provide reliable and long-lasting performance in various infrastructure projects.

- Q: Ductile iron pipe connection mode

- The connection mode of ductile iron pipe installation program: clean up the socket socket to clean up on the apron, apron, pipe (tube), Jack in appearance and rubber brush lubricant to push the pipe into socket to check.

- Q: What are the advantages of using ductile iron pipe over HDPE pipe?

- Ductile iron pipe offers numerous benefits compared to HDPE pipe. Firstly, it is renowned for its exceptional strength and durability. With the ability to withstand higher pressure, it is less prone to leakage or bursting, making it an ideal choice for applications requiring high-pressure water or gas transmission, such as municipal water supply systems or industrial piping networks. Secondly, ductile iron pipe boasts an extended lifespan when compared to HDPE pipe. Its remarkable resistance to corrosion allows it to endure for decades, even in harsh environmental conditions. As a result, frequent replacements are minimized, leading to long-term cost savings. Furthermore, ductile iron pipe exhibits excellent fire resistance properties. It can endure high temperatures without compromising its structural integrity, making it a reliable option for applications where fire safety is a concern, such as fire hydrant systems or sprinkler systems. Additionally, ductile iron pipe is renowned for its superior flow characteristics. Its smooth inner surface reduces friction loss, facilitating efficient and consistent fluid flow. This attribute is particularly crucial in applications that necessitate maximum flow capacity, such as water distribution systems or wastewater treatment plants. Moreover, ductile iron pipe is highly recyclable, promoting environmental sustainability. It can be melted down and utilized to manufacture new pipes, thereby reducing its environmental impact. In conclusion, ductile iron pipe offers a multitude of advantages over HDPE pipe, including its exceptional strength and durability, prolonged lifespan, fire resistance, superior flow characteristics, and recyclability. These features establish ductile iron pipe as the preferred choice for various applications, particularly those that require high-pressure transmission, longevity, fire safety, efficient flow, and environmental sustainability.

Send your message to us

Ductile Iron Pipe Class L10 Low Price Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 299 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords