Ductile Iron Pipe ,K9 with High Quality Popular

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ductile Iron Pipe ,K9 with High Quality

Product Description

CNBM ductile iron pipe ranges from DN80-DN2000mm (Tyton, T-Type, Class K7/K8/K9), effective length: 6m, complying with ISO2531and EN545 standards.

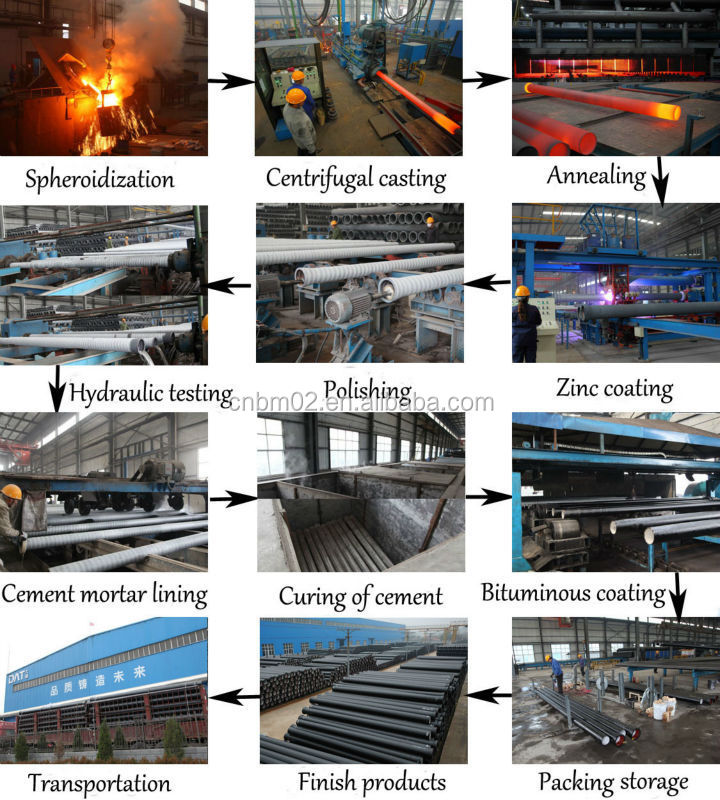

Technical Process

DN80 Ductile Iron Pipe Manufacturer

Specification

Internal lining: Pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating: Pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing: Pipes from DN100 to DN300 be bundled with steel belts, others are in bulk.

Packaging & Shipping

Packing: in bulk or container.

Our Services

Trustworthy financial strength.

One-stop shopping.

Fast and efficient service.

Coordination of shipments from multiple plants.

Specialists of the overseas shipping process.

A more competitive price.

Company Information

CNBM International Corporation is the leading production base and renowned supplier of Ductile Iron Water Pipe systems of both potable and waste water in China. We are constantly looking to develop high quality products to ensure the longest service life and wonderful performance.

CNBM Pipelines regard quality as the essential factor leading to successful business. Every pipe is tested in accordance with BS EN545 (water application) or BS EN598 (sewer application). CNBM Pipelines products comply with and are tested according to the relevant European and International Standards. Our pipes are manufactured under the quality management system BS EN ISO 9001. After years of efforts, CNBM Pipelines has built up great reputation in terms of quality and service among customers worldwide.

- Q: Can ductile iron pipe be used for sewer and wastewater systems?

- Indeed, sewer and wastewater systems can make use of ductile iron pipe. Ductile iron, a variant of cast iron, boasts enhanced attributes such as heightened durability, strength, and flexibility. These characteristics render it apt for subterranean usage, encompassing sewer and wastewater systems. Ductile iron pipes possess resistance against corrosion and are capable of enduring high-pressure circumstances, rendering them perfect for the conveyance of sewage and wastewater. Furthermore, ductile iron pipes boast an extended lifespan and necessitate minimal upkeep, thereby making them a financially prudent alternative for sewer and wastewater infrastructure.

- Q: Can ductile iron pipes be repaired if they are damaged?

- Ductile iron pipes can undergo repairs if they sustain damage. The necessary repair method will depend on the extent of the damage. In instances where the pipe is cracked or has small holes, a repair clamp or a stainless-steel sleeve can be utilized to seal the affected area. These approaches offer a temporary solution, allowing water to continue flowing until a more permanent fix can be implemented. For more severe damage, such as significant cracks or broken segments, a complete replacement may be required. This process entails removing the damaged section of the pipe and installing a new piece. It is a specialized task that demands specific equipment and expertise, but it effectively restores the pipe's functionality. It is crucial to note that only trained professionals with experience in working with ductile iron should carry out the repairs. This ensures proper execution and safeguards the integrity and safety of the pipeline system. Regular inspection and maintenance of ductile iron pipes can aid in early detection of potential issues, preventing extensive damage that may necessitate replacement instead of repair.

- Q: Can ductile iron pipe be used for bridge crossings?

- Ductile iron pipe is suitable for bridge crossings due to its strength, durability, and flexibility. Its high tensile strength enables it to bear heavy loads and vibrations, making it ideal for supporting bridges and withstanding traffic weight. Moreover, the pipe's flexibility allows it to absorb movements and deformations caused by temperature changes, settling, and other factors, minimizing the risk of structural damage and ensuring the bridge crossing's longevity. Additionally, the pipe's resistance to corrosion makes it a dependable choice for bridge crossings exposed to moisture, chemicals, and other corrosive elements. Overall, ductile iron pipe possesses properties that make it a reliable and appropriate material for bridge crossings.

- Q: How does ductile iron pipe perform in areas with high soil stability?

- Ductile iron pipe performs exceptionally well in areas with high soil stability. Due to its inherent strength and durability, ductile iron pipe can withstand the pressure exerted by the soil without any significant deformation or failure. The high soil stability ensures that there are minimal ground movements, settling, or shifting, which further contributes to the excellent performance of ductile iron pipe. In areas with high soil stability, the pipe is less prone to experiencing external forces or stresses that could potentially cause damage. Ductile iron pipe has a high resistance to corrosion, abrasion, and impact, making it highly suitable for such conditions. The material's robustness allows it to withstand the weight and pressure of the soil, ensuring the structural integrity of the pipe is maintained over time. Moreover, ductile iron pipe's flexibility and joint design contribute to its performance in areas with high soil stability. The pipe's ability to accommodate small movements and minor ground shifts without compromising its integrity is advantageous in these stable soil conditions. The restrained joint system used in ductile iron pipe installations provides additional support and stability, minimizing the risk of pipe dislocation or failure. Overall, ductile iron pipe is a reliable and efficient choice for areas with high soil stability. Its strength, durability, and resistance to external forces make it well-equipped to handle the demands of such environments. Additionally, the pipe's flexibility and joint design ensure that it can adjust to minor soil movements, thus further enhancing its performance in these conditions.

- Q: How does ductile iron pipe perform in high-velocity flow conditions?

- The performance of ductile iron pipe is exceptional in conditions with high-velocity flow. It can endure the forces exerted by these flows without experiencing significant damage or failure, thanks to its unique properties like high tensile strength and impact resistance. One advantage of ductile iron pipe is its ability to withstand water hammer, which is a sudden increase in pressure caused by the rapid deceleration or change in direction of water flow. This is particularly crucial in high-velocity flow conditions, where water velocity is significantly higher than normal. Ductile iron pipes are designed to absorb and dissipate the energy generated by water hammer, protecting the pipe and the surrounding infrastructure. Moreover, ductile iron pipe has excellent flow characteristics, ensuring smooth and efficient water transport even at high velocities. This is especially important in applications that require quick transportation of a large volume of water, such as industrial processes or fire protection systems. The smooth interior surface of ductile iron pipe minimizes friction and pressure losses, allowing water to flow freely and efficiently, reducing energy consumption and operating costs. Furthermore, ductile iron pipe is highly resistant to corrosion, which is a common issue in high-velocity flow conditions where the water may contain aggressive chemicals or particulates. The protective lining and coating systems used in ductile iron pipes create a barrier against corrosion, prolonging the lifespan of the pipe and maintaining its structural integrity. In conclusion, ductile iron pipe is ideal for high-velocity flow conditions due to its ability to withstand water hammer, excellent flow characteristics, and resistance to corrosion. Its strength, durability, and reliable performance make it a preferred choice for various applications, ensuring efficient water transport even in demanding environments.

- Q: General cast iron prices now

- Regular cast iron prices now range between 5000 and 8000.Ductile iron is a kind of high strength cast iron material developed in 50s twentieth Century, its comprehensive performance is close to the steel, it is based on its excellent performance, has been successfully used in casting complex stress, strength, toughness and wear resistance requirements of the higher parts. Nodular cast iron has developed rapidly to be second only to grey cast iron and widely used as cast iron material. The so-called "iron instead of steel", mainly refers to ductile iron.

- Q: Can the sealing ring of ductile iron pipe be reused?

- It is better not to have used things, easy aging, sealed, the best to use new

- Q: Can ductile iron pipe be used for cooling water systems?

- Yes, ductile iron pipe can be used for cooling water systems. Ductile iron pipes are known for their high strength and durability, making them suitable for various applications, including cooling water systems. They have excellent resistance to corrosion, which is important in preventing damage and maintaining the efficiency of the cooling water system. Additionally, ductile iron pipes can handle high-pressure and high-temperature conditions, making them a reliable choice for this purpose.

- Q: How are ductile iron pipes different from cast iron pipes?

- Ductile iron pipes are different from cast iron pipes in terms of their composition and properties. Ductile iron pipes are made from a type of cast iron that has been treated with magnesium to improve its strength and flexibility. This makes ductile iron pipes more durable, impact-resistant, and less prone to cracking or breaking compared to traditional cast iron pipes. Additionally, ductile iron pipes have a higher tensile strength, allowing them to withstand higher internal and external pressures. In summary, ductile iron pipes are a more modern and advanced version of cast iron pipes, offering improved performance and longevity.

- Q: What material is ductile cast iron 235A?

- Nodular cast iron by spheroidization and inoculation by spherical graphite, effectively improve the mechanical properties of cast iron, especially the plasticity and toughness increased, resulting in higher than carbon steel. The strength of nodular cast iron is a kind of high strength cast iron material developed in 50s twentieth Century, its comprehensive performance is close to the steel. It is based on its excellent performance, has been successfully used in casting complex stress, strength, toughness and wear resistance requirements of the higher parts. Ductile iron has been the rapid development of cast iron material for application of gray cast iron, only very widely. The so-called "iron steel", mainly refers to the ductile iron.

Send your message to us

Ductile Iron Pipe ,K9 with High Quality Popular

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords