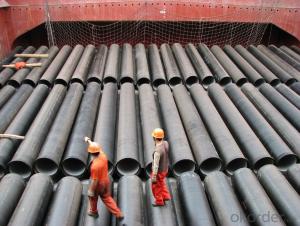

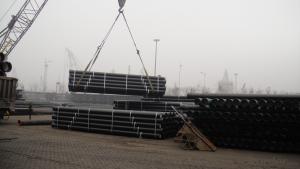

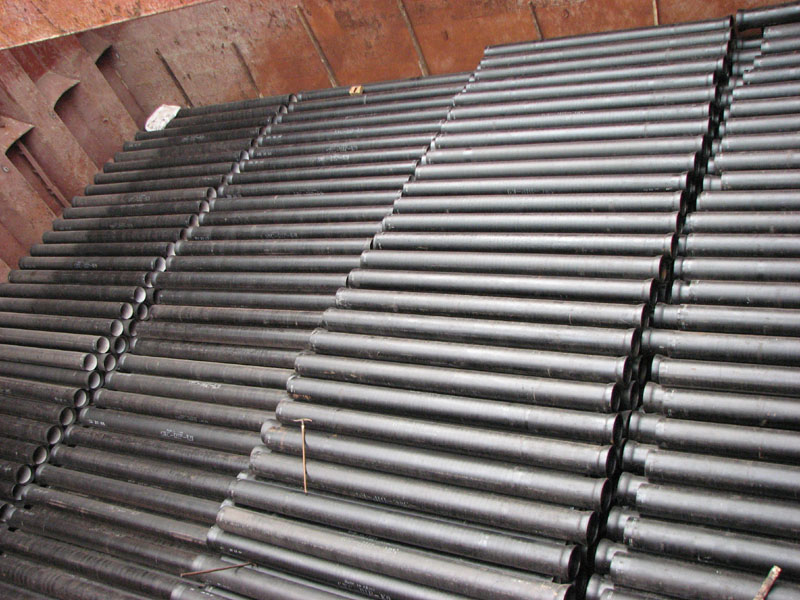

Ductile Iron Pipe On Sale From China with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Place of Origin: China (Mainland)

Model Number: T type / K type / Flange type

Length: 6M/NEGOTIATED

Standard: ISO2531 and EN545

Application: Potable/Sewage Water

Diameter: DN80~DN1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: STANDARD

Pull Strength: 420 Yield (≥ MPa): 300

Material: Cast Iron

Type: Ductile Iron Pipes

Certification: ISO2531 and EN545

Specification: DN80~DN1600

Outer Diameter: 80-1600

Thickness: standard

Usage: water pipe Packaging & Delivery

Packaging Details: DN80~DN300 are bundled with steel belts, others are in bulk condition.

Specification& Payment terms

Internal lining: Pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating: Pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing: Pipes from DN100 to DN300 be bundled with steel belts, others are in bulk.

Payment term: L/C, T/T.

Packing: In bulk vessel or in container.

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: What is the expected burst pressure of ductile iron pipes?

- The expected burst pressure of ductile iron pipes can vary depending on various factors such as the pipe diameter, wall thickness, and the specific grade of ductile iron used. However, in general, ductile iron pipes typically have a burst pressure ranging from 350 to 700 psi (pounds per square inch).

- Q: How does ductile iron pipe handle changes in pipe diameter or size?

- Ductile iron pipe is designed to handle changes in pipe diameter or size with relative ease. It possesses excellent flexibility and can accommodate variations in pipe dimensions without compromising its structural integrity. This is mainly due to its unique composition, which includes a significant amount of graphite nodules that provide ductility and elasticity to the material. When faced with changes in pipe diameter or size, ductile iron pipe can be easily manufactured or modified to meet specific requirements. It can be cast or fabricated in various diameters and lengths, allowing for seamless integration and adaptability within a pipeline system. This versatility is particularly beneficial in scenarios where different pipe sizes need to be connected or when the pipeline layout requires alterations. Moreover, ductile iron pipe's superior mechanical properties make it capable of withstanding the stresses and forces associated with changes in pipe diameter or size. It exhibits high tensile strength, impact resistance, and durability, ensuring that it can handle the internal and external pressures exerted on the pipe during operations. Additionally, the jointing systems used with ductile iron pipe contribute to its ability to handle changes in diameter or size. Various joint types, such as push-on, restrained, or mechanical joints, provide secure and leak-free connections between different pipe sections. These joints allow for easy assembly and disassembly, enabling efficient adjustments to the pipe diameter or size as needed. In conclusion, ductile iron pipe is well-equipped to handle changes in pipe diameter or size due to its inherent flexibility, adaptability, and robustness. Its composition, manufacturing capabilities, and jointing systems all contribute to its ability to accommodate variations in pipe dimensions without compromising its performance.

- Q: Do rigid cement cast iron pipes need cement piers?

- Ductile iron pipes mainly called centrifugal ductile iron pipe, it has the properties of nature, iron and steel, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc.. Water supply pipe is the first choice, with high cost performance. Compared with the PE pipe, from the installation time, ductile pipe PE pipe installation is simple and rapid, and after the installation of internal and external pressure bearing better tightness and corrosion resistance; from the point of view, ductile pipe sealing better after installation, but also can improve the corrosion resistance of corrosion protection through a variety of means; from the hydraulic performance, because ductile pipe specifications generally refers to the inner diameter of PE pipe diameter specifications generally refers to the same specifications, because under the condition of ductile pipe can achieve greater runoff; from the installation and maintenance cost, ductile pipe have more favorable price. The main components of ductile iron pipes are carbon, silicon, manganese, sulfur, phosphorus and magnesium. The inner wall of zinc spray, anti-corrosion materials such as cement mortar.

- Q: Can cast iron pipes not be used for domestic water supply and drainage?

- Can be used for life drainage, I last year to do the public construction, 24 layers of life and drainage on the cast iron pipe.

- Q: How can the cast iron pipe of the ductile iron pipe be repaired?

- First of all, to see whether the manufacturers do elbow pressure did not reach, if it is. That can only be replaced, if not, with a cast iron electrode welding repair.By the way, ductile iron can only be welded and not welded.

- Q: Can the sealing ring of ductile iron pipe be reused?

- The sealing ring is hard to install and take off. I have been in this line for six years. I haven't seen it removed. The rubber ring itself is not expensive. It is not necessary to reuse it.

- Q: What is the minimum operating temperature for ductile iron pipes?

- The minimum operating temperature for ductile iron pipes is typically -40 degrees Celsius. Ductile iron has excellent strength and ductility even in cold temperatures, making it suitable for a wide range of applications, including water and wastewater systems. However, it is important to note that the specific minimum operating temperature can vary depending on factors such as the specific grade of ductile iron used and the application requirements. It is always recommended to consult the manufacturer's specifications and guidelines to ensure proper usage and performance of ductile iron pipes in cold temperatures.

- Q: Can ductile iron pipes be used for cooling water systems?

- Indeed, cooling water systems can utilize ductile iron pipes. Renowned for their resilience, robustness, and resistance to corrosion, ductile iron pipes are a fitting choice for various applications, including cooling water systems. With the ability to withstand high pressure and temperature fluctuations, these pipes excel in circulating and transporting cooling water. Moreover, their smooth interior surface mitigates friction, diminishing the likelihood of scaling or blockages and enabling the efficient flow of cooling water. Consequently, ductile iron pipes emerge as a dependable and efficient option for cooling water systems.

- Q: Can ductile iron pipe be used for hydroelectric power generation?

- Hydroelectric power generation is made possible with the use of ductile iron pipes. Ductile iron, a type of cast iron known for its strength, durability, and resistance to corrosion, is well-suited for a range of applications, including the construction of hydroelectric power generation systems. One specific application of ductile iron pipes in hydroelectric power plants is for water conveyance. These pipes, commonly referred to as penstocks, play a vital role in transporting water from the reservoir to the turbines. Given the high pressure and flow rates involved, ductile iron pipes are capable of withstanding these demanding conditions. Moreover, the resistance of ductile iron pipes to corrosion is particularly essential in hydroelectric power generation. The water used in this process can be highly corrosive due to its composition and the presence of impurities. By utilizing ductile iron pipes, the system remains sturdy and durable over time, resulting in reduced maintenance and replacement expenses. Furthermore, the versatility of ductile iron pipes allows for easy joining using different methods such as flanged, mechanical, or push-on joints. This facilitates efficient and reliable installation, ensuring the integrity of the water conveyance system in hydroelectric power plants. In conclusion, ductile iron pipe is a suitable choice for hydroelectric power generation due to its strength, durability, corrosion resistance, and ease of installation. Its utilization in penstocks and other water conveyance systems contributes to the efficient and dependable operation of hydroelectric power plants.

- Q: How are ductile iron pipes protected from external damage?

- Ductile iron pipes are protected from external damage through the application of protective coatings. These coatings act as a barrier, shielding the pipes from corrosion and other forms of external damage. Additionally, the pipes may be encased in concrete or installed in a casing pipe to provide further protection against external forces and impacts.

Send your message to us

Ductile Iron Pipe On Sale From China with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords