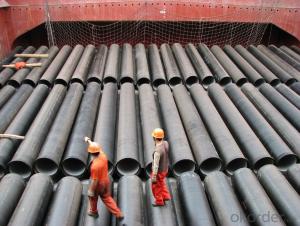

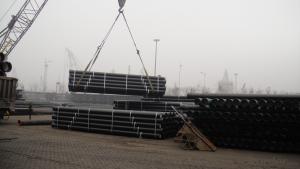

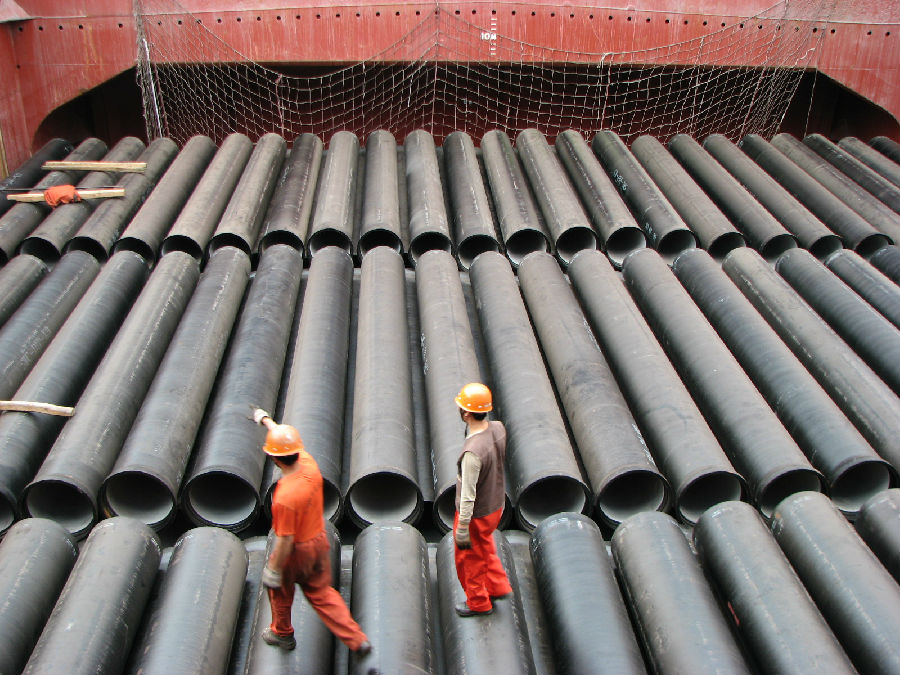

Ductile Iron Pipe On Sale Made In China with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Maximum pipe diameter of ductile iron pipe

- What I know is that the new ductile iron pipes can reach 2400MM, which can be checked by the official website

- Q: How can the internal and external walls of ductile iron pipes be protected from corrosion?

- The inner wall is not needed and the outer wall is painted

- Q: What are the different methods for testing ductile iron pipe?

- To ensure the quality and reliability of ductile iron pipe, there are several available testing methods: 1. The most commonly used method is hydrostatic testing. This involves filling the pipe with water and pressurizing it to a specific level. The pipe is then inspected for leaks or deformations under the applied pressure. Hydrostatic testing determines the pipe's ability to withstand internal pressure without failing. 2. Tensile testing involves subjecting a sample of the ductile iron pipe to an increasing tensile load until it fractures. This test measures the material's ultimate tensile strength, yield strength, and elongation. It assesses the pipe's mechanical properties and ability to withstand tension without breaking. 3. Hardness testing measures the pipe's hardness using techniques such as Brinell, Rockwell, or Vickers hardness tests. This provides information about the material's resistance to deformation, wear, and fatigue. It evaluates the pipe's durability and resistance to external forces. 4. Impact testing entails striking a notched sample of the ductile iron pipe with a pendulum or falling weight to measure its impact resistance. This test determines the material's ability to absorb energy during sudden loading or impact. It evaluates the pipe's ability to withstand accidental impacts or dynamic loads. 5. Ultrasonic testing is a non-destructive method that uses high-frequency sound waves to detect internal defects or discontinuities in the ductile iron pipe. This testing identifies voids, cracks, or inclusions that may affect the pipe's structural integrity. It ensures the pipe's soundness and reliability. 6. Magnetic particle testing primarily detects surface or near-surface defects in the ductile iron pipe. It involves applying a magnetic field to the pipe and then applying magnetic particles to the surface. Any defects will cause the particles to gather and form visible indications. This testing identifies surface cracks, laps, or other defects that may affect the pipe's performance. By utilizing these various testing methods, ductile iron pipe can meet industry standards and specifications, guaranteeing its quality and reliability in various applications.

- Q: What are the specifications for the installation of water ball iron pipes?

- Groove support: according to the groove soil, groundwater, slotted cross section, load conditions and other factors, the design requirements are firm and reliable, to prevent landslides, support, shall not impede the lower pipe and stable pipe.

- Q: Can ductile iron pipe be used for irrigation pumping stations?

- Indeed, irrigation pumping stations can utilize ductile iron pipe. This type of pipe finds widespread application, particularly in irrigation systems, owing to its robustness and resilience. Its exceptional tensile strength enables it to endure substantial pressure and weight, rendering it highly suitable for irrigation pumping stations. Furthermore, ductile iron pipe exhibits resistance to corrosion, a desirable trait in the presence of water within irrigation systems. Moreover, its ease of installation and maintenance make it an economical selection for irrigation projects.

- Q: Can ductile iron pipe be used for wastewater treatment plant applications?

- Ductile iron pipe is indeed applicable for wastewater treatment plant purposes. Its suitability stems from several properties it possesses. Firstly, its high resistance to corrosion is crucial in such plants, where the presence of chemicals and water can cause pipe rust and degradation. Moreover, its high tensile strength and durability enable it to withstand the demands of wastewater treatment processes. Furthermore, its flexibility facilitates easy installation and maintenance within intricate wastewater treatment systems. In conclusion, ductile iron pipe is a dependable and cost-effective option for wastewater treatment plant applications.

- Q: What are the different methods for cutting ductile iron pipe?

- There are several different methods for cutting ductile iron pipe, depending on the specific requirements and constraints of the project. Some common methods include: 1. Manual Cutting: This method involves using a handheld saw or grinder with an abrasive cutting wheel to cut through the ductile iron pipe. It is a simple and relatively inexpensive method, but it can be labor-intensive and time-consuming for larger pipe sizes. 2. Mechanical Cutting: Mechanical cutting methods involve using specialized machinery to cut through the ductile iron pipe. This can include bandsaws, pipe cutters, or hydraulic cutting machines. These machines can provide faster and more precise cuts, especially for larger pipe sizes. However, they can be more expensive and require skilled operators. 3. Torch Cutting: Torch cutting, also known as oxyfuel cutting, involves using a torch to heat the ductile iron pipe and then introducing a high-pressure oxygen stream to create a chemical reaction that cuts through the metal. This method is effective for cutting thick-walled ductile iron pipe, but it can generate a significant amount of heat and sparks, requiring proper safety precautions. 4. Plasma Arc Cutting: Plasma arc cutting utilizes a high-velocity jet of ionized gas (plasma) to melt and cut through the ductile iron pipe. This method is ideal for cutting through thick-walled pipes where precision and efficiency are required. However, it can be more expensive and may require specialized equipment and training. 5. Waterjet Cutting: Waterjet cutting uses a high-pressure jet of water mixed with an abrasive material to cut through the ductile iron pipe. This method is highly precise and does not generate heat or sparks, making it suitable for cutting in sensitive environments. However, it can be slower and more expensive compared to other cutting methods. It is important to consider factors such as pipe size, project requirements, budget, and safety when selecting the appropriate method for cutting ductile iron pipe. Consulting with professionals or experts in the field can help determine the most suitable method for a specific project.

- Q: Some questions about the bearing capacity of nodular cast iron pipes!

- The minimum tensile strength of ductile iron is 400MPa, and the stresses can be calculated according to the wall thickness, diameter and safety factor.

- Q: Can ductile iron pipes be used for irrigation of golf courses?

- Certainly, ductile iron pipes are applicable for the irrigation of golf courses. Renowned for their durability, strength, and resistance to corrosion, these pipes are suitable for a wide range of uses, including irrigation systems. They possess the ability to endure high-pressure water flow and are less prone to cracking or breaking when compared to alternative materials. Moreover, ductile iron pipes boast an extended lifespan, minimizing the necessity for frequent maintenance or replacement. Consequently, they represent a dependable option for the irrigation of golf courses, where a continuous and efficient water supply is imperative for sustaining healthy turf and landscaping.

- Q: What is a graphite cast iron pipe?

- There is a graphite tube, but there is no graphite cast iron (if not ductile iron)

Send your message to us

Ductile Iron Pipe On Sale Made In China with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords