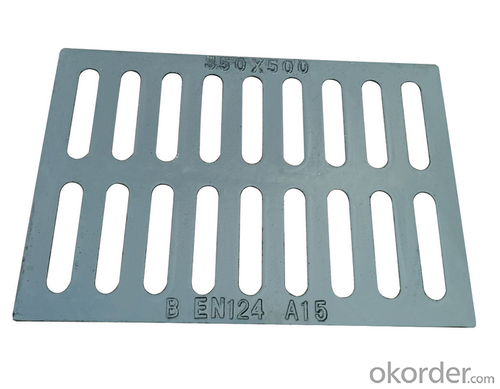

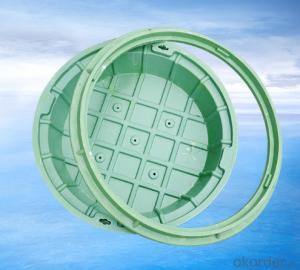

Ductile Iron Manhole Cover with EN124 C250

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product introduction

1. High load strength

Less noise and lower vibration transmissions.

2. Against theft,noise and rust.

3. Durable life.

4. Free design

Class A15 Area which can only be used by pedestrians and pedal cyclists

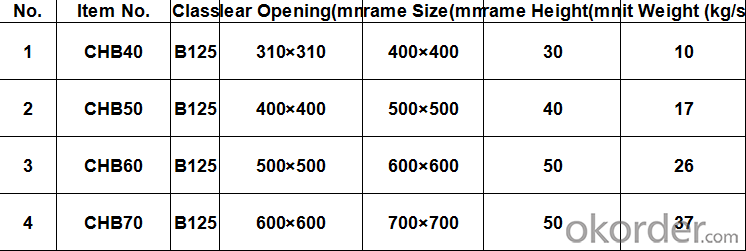

Class B125 Folkways, pedestrian areas and comparable areas, car parks or parking decks

Class C250 For gratings installed in the area of kerbside channels of roads which, when measured from the Serb edge, extend maximum 0.5 m into the carriageway and maximum 0.2 m into the foot way

Class D400 Arrive ways of roads (pedestrian streets included), hard shoulders and parking areas for all types of road vehicles.

Class E600 Areas subject to high axle loads such as docks and airports

Class F900 Areas subject to very high axle loads such as airports

Specification

1.Standard:ISO9001,EN124

2.Applicable medium:gases,liquids,steam

3.Material:ductile iron,Gray cast iron

Tested item standard

Anti-breaking strength (Mpa)>14

Impact toughness resistance (kg/cm2)>95

Tensile strength (Mpa)>10

Compressive strength (Mpa)>30

Modulus of elasticity(kg/cm2)>1.4*104

Cold-hot resistance measure<0.4< span="">

Water-absorption<1.0< span="">

Surface treatment

Black bitumen coated and hot gavanized

Smooth surface and anti-theft

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Company Information

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

About Sample

Q : Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

About Package

Q: Can I change your package Way?

A: Yes, we can make the form of the package and transportation according to your request, but if any additional charge occurs, you have to pay for it.

About Customer Logo

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: What's the effect of casting copper?

- Copper is one of the main corrosion resistant alloys. When the mass fraction of copper in cast iron is from 0.25% to 1%, the corrosion resistance of copper in the industrial atmosphere can be obviously increased. But copper has very little corrosion resistance in lye or salt solution.Copper can increase the flowability of molten iron and improve its casting ability remarkably.Copper can increase the coercive force and residual magnetic force, but the permeability is not affected.Combined use of copper with other alloy elements, such as copper chromium, copper chromium molybdenum, copper molybdenum, copper manganese, copper vanadium, can achieve greater results.

- Q: What are the requirements for casting steel castings?

- 4 thickness, most should be placed above the.5 and try to reduce the number of.6, the sand core should be used in classification of flat surface

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- Tangshan Yongding automobile spare parts factory also give a lot of supply, casting factory of Tangshan n to the car enterprises casting wheel gearbox etc.The team of casting experts welcome you to ask questions and accept questions!

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- If it is Phosphating for painting, it is not necessary, because the surface of the casting is rough and can be firmly bonded with the paint film.

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- Q: The difference between sheet metal and casting parts

- Sheet metal refers to the metal sheet (which can be bent straight board, etc.) generally uniform thickness, can obtain the required parts by stamping, molding, welding, splicing and other processing methods.

Send your message to us

Ductile Iron Manhole Cover with EN124 C250

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches