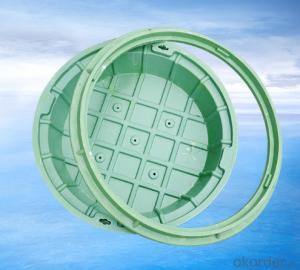

Ductile Iron Manhole Covers C250 with EN124 High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 4300 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1.Advantages: Good compressive, bending and impact strenth,anti-corrosion, not rust, long service life

(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

2.Applications: water supply and drainage, fire engineering, natural gas,electricity and telecommunications, street lamp and outdoor illuminations.

3.Designs: based on EN124 standard and according to customer's drawing or samples.

4.Color: black, Grey, green, blue and Marble , etc.

5.Inspection: in-house or the third party as per customer's request.

Features

1.High Intensity

It adopts macromolecule complex material and reinforcing steel bar moulded by high temperature and press at one time.

2.Durable

Acid-alkali and corrosion resistance; anti-rust; insulation; weatherability; excellent anti-pressure capability.

3.Unique appearance

Rich colors;the cover is not sprayed in surface but painted in whole material so that the color can keep lasted.

4.Competitive price

The price of compound manhole cover is lower than stipulated standard cast iron ones.

5.Save mine resource

It is made by regenerated resin or regenerated plastic raw material, which save application of cast iron.

Packing

Ductile Iron Manhole Cover and Grating

Our Company

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group. CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

FAQ

1. Can I negotiate the Prices?

Yes, we may consider discounts for bulk orders.

2. What is your minimum order requirement?

We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

3. How long will it take to execute my order?

For the stock items , we can arrange the shippment within 3-5 days after received your payment . For the customized items , we will indicate the delivery time in the quotation sheet .

4. Can you give warranty of your products?

Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with SYI 's quality or service. For the overseas orders,if there is quality problem , please kind to provide the pictures to show the problems by e-mail . We will provide the replacements to you at our cost according to actual conditions.

- Q: What are the casting parts used to test shrinkage holes?

- 1. anatomy. It is easy to slack off by sawing and machining.

- Q: Why does the precision casting factory not usually make iron castings?

- Jiangyin Lin Xing stainless steel (precision manufacturing) Co., Ltd. to provide professional precision casting

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: What is the difference between casting and stamping parts?

- Cold stamping is generally no longer done by cutting, or only a small amount of cutting is required. The precision and surface state of hot stamping parts are lower than those of cold stamping parts, but they are better than those of castings and forgings, and the amount of cutting is less.Stamping is mainly based on process classification, can be divided into separation process and forming process two major categories.

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- (3) to prevent generating white grey cast iron, in addition to taking measures from the process, must make the wall thickness is not too thin (some sources indicate that the corner wall thickness above 15mm, metal type casting must be in the corner, for Aluminum Alloy, magnesium alloy casting casting casting Create fillet should not be less than 3-4m, for casting round cast iron, copper alloy mould casting can see table 1.1-32 selection; (5) because of the metal and the core without let, for the convenience of the casting is taken out and the draw out type, slope casting casting should be suitably large than sand casting metal casting. General 30%-50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction and metal surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal castings the type should be given greater inclination, all kinds of metal type alloy casting casting casting.

- Q: The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

Send your message to us

Ductile Iron Manhole Covers C250 with EN124 High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 4300 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches