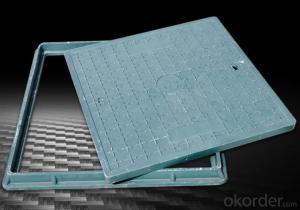

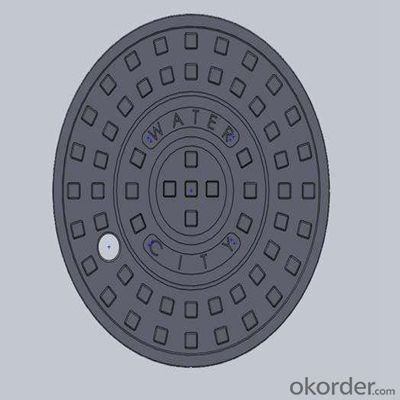

Ductile Iron Manhole Cover of Light Duty Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1) Designs: based on EN124 standard and according to customer's drawing or

samples.

2) Applications: water supply and drainage, fire engineering, natural

3)Surface treatment: Painting

4)Process: Casting. Deburring .Drilling .threading

5)Certification: ISO9001:2008

6)Standard: EN124 Standard

Advantages:

1.Higher quality /higher tensile

2.Higher security /long life

3.Possibilities of new locking systems

Packaging & Shipping:

Packaging: Details Pallet with bubble film, Carton or with pallet.

Delivery Detail: 8 days if your order is 20"container.

Specification:

| No. | Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Size(mm) | Unit Weight (kg/set) |

| 1 | PCE300 | C250 | 200×200 | 300×300 | 35 | 8 |

| 2 | PCE400 | C250 | 300×300 | 400×400 | 40 | 22 |

| 3 | PCE500 | C250 | 400×400 | 500×500 | 45 | 26 |

| 4 | PCE550 | C250 | 500×500 | 550×550 | 45 | 30 |

Our Services:

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.

Meanwhile, a number of experienced workers do the strictly Quality control and have

production tracking program.

5. Our price: we are the factory,

we provide the most competitive price with good quality, and

large order quantity will get big support by us!

6. Professional technical support with free charge.

Pictures:

FAQ:

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Single for this problem, the direct casting out of course good. But many times because of the limitations of the process, so we choose the post-processing hole

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: Cause of choking of casting parts

- Is it boiling from the picture? Does it sound like a fire? If not, it's not choking. I feel like choking. The gas doesn't drain out

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

- Q: The difference between sheet metal and casting parts

- Sheet metal refers to the metal sheet (which can be bent straight board, etc.) generally uniform thickness, can obtain the required parts by stamping, molding, welding, splicing and other processing methods.

Send your message to us

Ductile Iron Manhole Cover of Light Duty Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches