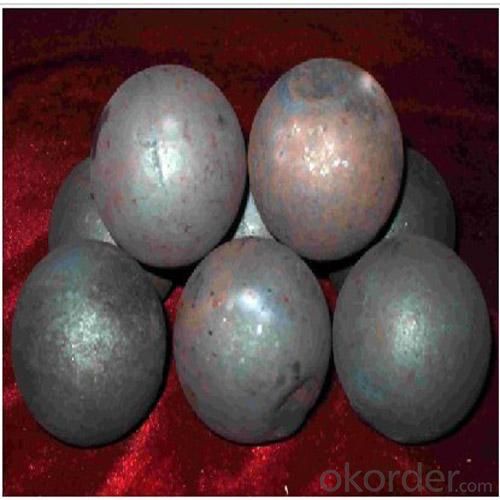

High Chrome Casting Balls for Mining

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information for High Chrome Casting Balls for Mining

CMAX high chrome casting balls for mining has good quality in the best price.

High Chrome Casting Balls

Chrome content:11-14%

Size: dia30-100mm

Hardness: dia30-70mm HRC58-63

dia80-100mm HRC57-62

Specifications of High Chrome Casting Balls for Mining

1. High hardness

2. Good wear resistance

3. High toughness

4. No mal-roundness

Application of High Chrome Casting Balls for Mining

cement,metallury, mine,construction mateial and slurry

We are a professional manufacturer which produce media ball.Our steel ball exported to Chile,south Africa,Iran,Russia,USA etc.Nowadays,We have annual production capacity of 50,000 MT.

Chemcial Elements of Chrome Steel Ball

Specification and Hardness of Chrome Steel Ball

Weigh of Chrome Steel Ball

Chrome Steel Ball Packing

Steel drum: 800-1000kgs;

Container bag: 1000kgs.

- Q: Why does the precision casting factory not usually make iron castings?

- Jiangyin Lin Xing stainless steel (precision manufacturing) Co., Ltd. to provide professional precision casting

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Yes, casting drawings are casting drawings with machining allowances, slopes, and gating systems

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine,

- Q: What kind of flaw detector is better for casting parts?

- Casting using the detector test, you must first determine the detection process, such as the detection of surface and near surface crack defects, such as casting, recommended by CYD-3000, or CYD-5000 mobile magnetic testing machine for testing.

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Chrome Casting Balls for Mining

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords