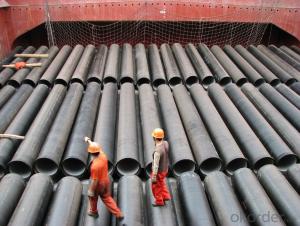

Ductile Iron Pipe On Sale Made In China DN100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Packaging & Delivery

Packaging Detail: | DN80-300 bundled with steel belt ( the bundle size see the product detail part) DN400-1200 are in bulk |

Delivery Detail: | at least 5days for MOQ |

2.Specifications

Ductile iron pipe comply with ISO2531/EN545

1)We are factory

2)Best quality

3)Competive price

4)On time delivery

3.Features:

Facilitating high resistance to loadings, pressure and vacuum with high tensile strength,

Enabling high resistance to corrosion,

Not requiring cathodic protection,

Less operating cost since cast pipes have larger nominal diameter than polyethylene pipes.

Being the best pipe in case of an earthquake, with its ability of resilience and resistance to impacts without deformation,

Long product life, exceeding 50 years,

Preserving the quality of water with healthy interior coating.

4.Applied Standards:

General Design | ISO 2531 |

Internal Lining | ISO 4179 |

External Coating | ISO 8179 |

Polyethylene Coating (Optional) | ISO 8180 |

5.Joint Types:

Push-on Type | TYT Type |

Standard Type |

6. Diameters:

Pipes | Ø80 – Ø1200 mm (L = 6m, and 5.7m) |

Fittings | Ø80 - Ø2200 mm |

7. Wall Thickness:

Pipes | C and K classes |

Fittings | Class K10 - K12 |

8.Test Pressures:

Pipes | for Ø80 - Ø300 mm | 50 bar / 40 bar |

for Ø350 - Ø600 mm | 40 bar / 30 bar | |

for Ø700 - Ø1000 mm | 32 bar / 25 bar | |

for Ø1100 - Ø2600 mm | 25 bar |

Fittings | for Ø40 - Ø300 mm | 25 bar (*) |

for Ø350 - Ø600 mm | 16 bar | |

for Ø700 - Ø2600 mm | 10 bar | |

(*16 bar for fittings with PN10 flanges) | ||

9.Materials:

Pipe | Ductile iron casting, minimum 420 MPa tensile strength |

Internal Lining | Concrete Lining, ISO 4179 |

Socket Internal 10.Lining | 200 micron epoxy coating |

External Coating | 70 micron bitumen coating on 130 gr/m2 zinc coating, ISO 8179 |

Fittings | Ductile iron casting, minimum 420 MPa tensile strength |

Internal Lining | Concrete Lining, ISO 4179 |

External Coating | 70 micron bitumen coating on 130 gr/m2 zinc coating, ISO 8179 |

- Q: How do ductile iron pipes handle dynamic loads?

- Ductile iron pipes possess remarkable strength and durability, enabling them to effectively manage dynamic loads. These pipes exhibit a high resistance to bending and can endure the pressure and stress exerted on them when exposed to dynamic loads, such as water hammer or ground movement. The distinctive composition of ductile iron, which includes a small amount of carbon and the addition of magnesium, produces a structure that is both robust and flexible. This combination allows the pipes to flex when impacted by dynamic loads, rather than fracturing or breaking like other materials. Moreover, ductile iron pipes demonstrate a superior impact resistance, enabling them to absorb and distribute the energy generated by dynamic loads throughout their structure. This capability to dissipate energy effectively minimizes the risk of pipe failure and ensures the longevity of the pipeline system. Additionally, ductile iron pipes exhibit excellent stress distribution properties, ensuring that the load applied to the pipes is evenly dispersed along their length. This feature serves to prevent localized stress concentrations and reduces the likelihood of damage or failure. To summarize, ductile iron pipes are specially designed to handle dynamic loads with utmost efficiency. Their strength, flexibility, impact resistance, and stress distribution properties make them highly suitable for applications where dynamic loads are a concern, guaranteeing the reliability and longevity of the pipeline system.

- Q: Can ductile iron pipe be used for wastewater treatment plant applications?

- Ductile iron pipe is indeed applicable for wastewater treatment plant purposes. Its suitability stems from several properties it possesses. Firstly, its high resistance to corrosion is crucial in such plants, where the presence of chemicals and water can cause pipe rust and degradation. Moreover, its high tensile strength and durability enable it to withstand the demands of wastewater treatment processes. Furthermore, its flexibility facilitates easy installation and maintenance within intricate wastewater treatment systems. In conclusion, ductile iron pipe is a dependable and cost-effective option for wastewater treatment plant applications.

- Q: Are ductile iron pipes available in different wall thicknesses?

- Yes, ductile iron pipes are available in different wall thicknesses. Ductile iron pipes are manufactured with various wall thicknesses to meet different requirements and applications. The wall thickness of a ductile iron pipe is determined based on factors such as the pipe's diameter, the internal pressure it needs to withstand, and the soil conditions it will be installed in. Pipes with thicker walls are typically used for higher pressure applications or in areas with more challenging soil conditions, while thinner-walled pipes may be suitable for lower pressure applications. The availability of different wall thicknesses allows for flexibility in selecting the appropriate ductile iron pipe for specific projects and ensures that the pipes can efficiently and safely transport fluids or gases.

- Q: What is the expected corrosion protection system for ductile iron pipes?

- Typically, the expected corrosion protection system for ductile iron pipes involves a combination of external coatings, internal linings, and cathodic protection. To protect against corrosion, external coatings are applied to the pipe's exterior surface. These coatings, usually fusion-bonded epoxy, polyethylene, or polyurethane, act as a barrier against corrosion from soil, water, and chemicals. Furthermore, they play a crucial role in prolonging the pipe's lifespan. In order to safeguard against corrosion caused by the transported fluid, internal linings are applied to the pipe's interior surface. These linings, which can be made of cement mortar, epoxy, or polyurethane, provide a smooth and protective layer that prevents the formation of rust and scale. Cathodic protection is an electrochemical technique employed to shield ductile iron pipes from corrosion. It involves the utilization of sacrificial anodes or impressed current systems to generate a protective electrical current that counteracts the corrosion process. By employing this method, the formation of rust is prevented, thereby extending the pipe's longevity. It is important to acknowledge that the specific corrosion protection system for ductile iron pipes may differ depending on the application and environmental factors. To determine the appropriate corrosion protection system for a specific ductile iron pipe installation, consulting with corrosion experts and adhering to industry standards and guidelines is of utmost importance.

- Q: Can cast iron pipes not be used for domestic water supply and drainage?

- Can be used for life drainage, I last year to do the public construction, 24 layers of life and drainage on the cast iron pipe.

- Q: What are the different types of joints available for ductile iron pipe?

- There are several types of joints available for ductile iron pipe, each offering different benefits and suitable for different applications. Here are some of the most common types: 1. Mechanical Joints: These joints use a mechanical joint gland and rubber gasket to create a watertight seal. They are easy to install and allow for quick and simple disassembly if needed. 2. Push-on Joints: This type of joint features a rubber gasket that is compressed when the pipe is pushed into the fitting. It provides a reliable seal and requires no special tools for installation. 3. Restrained Joints: Restrained joints are designed to withstand higher internal pressures and prevent the pipe from pulling apart. They typically use a combination of mechanical or push-on joints with additional restraints such as thrust blocks or harnesses. 4. Flanged Joints: Flanged joints use flanges and bolts to connect two pipes together. They are commonly used in situations where frequent disassembly is required or when connecting to other types of pipes or equipment. 5. Welded Joints: In some cases, ductile iron pipes can be welded together to create a strong and permanent connection. Welded joints are typically used in large diameter pipes or specialized applications where a high level of strength is required. It is important to consider factors such as the pipe's application, pressure rating, and installation requirements when selecting the appropriate joint type for ductile iron pipes.

- Q: What's the difference between ductile iron pipe and cast iron pipe?

- We have to correct now basically all socket ductile iron pipes, because the socket type with a rubber ring, plus a ductile material, buried beneath it when the bearing has a certain flexibility, not because of the deformation and leakage phenomenon. To be used, not Unicom cast iron pipe socket, connection is used similar to the stainless steel hoop hoop sleeve closed.

- Q: Can ductile iron pipes be used for rainwater harvesting systems?

- Certainly, rainwater harvesting systems can utilize ductile iron pipes. Renowned for their robustness and resilience, ductile iron pipes prove to be fitting for a range of purposes, including rainwater harvesting. These pipes exhibit exceptional resistance to corrosion and are capable of withstanding considerable pressure, thereby ensuring the efficient conveyance of rainwater from the point of collection to storage tanks or distribution networks. Moreover, their impressively long lifespan diminishes the necessity for frequent replacements, rendering them a cost-effective option for rainwater harvesting systems.

- Q: How many casting methods are there in ductile iron casting? A 60*6 discus can not have sand holes. Its surface is smooth. What process can be used to make it?

- The metal mould is ok! The surface quality of the casting is better than that of the sand mold. But later heat treatment is needed.

- Q: Are ductile iron pipes suitable for use in brewery facilities?

- Yes, ductile iron pipes are suitable for use in brewery facilities. Ductile iron pipes are durable, corrosion-resistant, and can withstand high-pressure applications, making them ideal for transporting water, steam, and other fluids within brewery facilities. Additionally, the smooth interior surface of ductile iron pipes minimizes friction and prevents the build-up of sediments or organic materials, ensuring the purity and quality of the beer being produced.

Send your message to us

Ductile Iron Pipe On Sale Made In China DN100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords