Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 16

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

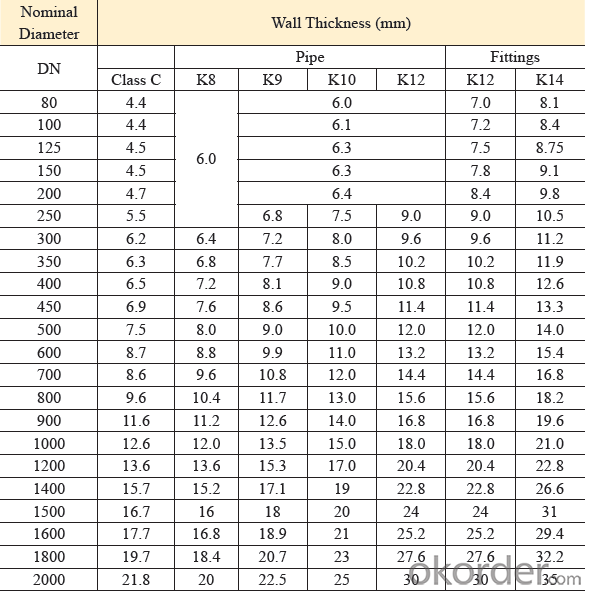

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

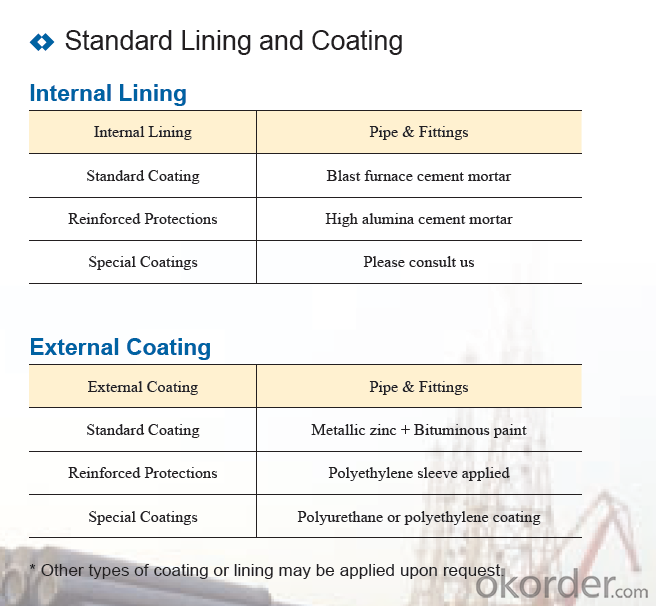

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

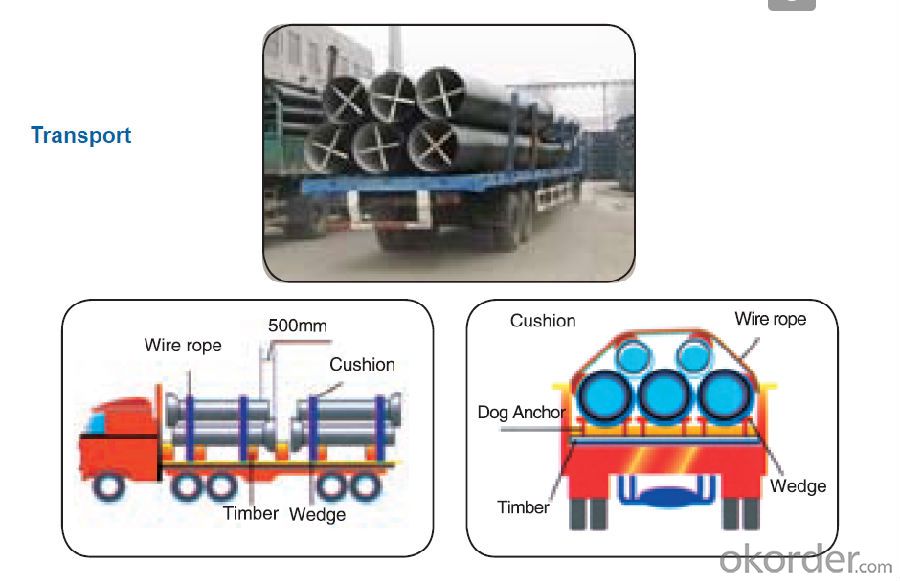

Transport:

- Q: How do ductile iron pipes perform in sandy soil conditions?

- Ductile iron pipes perform well in sandy soil conditions due to their inherent strength and durability. The material's high tensile strength allows it to withstand the pressure exerted by the surrounding soil, preventing pipe deformation and breakage. Additionally, the corrosion resistance of ductile iron ensures a longer lifespan, even in corrosive sandy soil environments.

- Q: Are ductile iron pipes suitable for use in cold climates?

- Ductile iron pipes are well-suited for cold climates due to their exceptional strength and durability. This makes them a reliable choice for various applications, such as water supply systems, sewage systems, and industrial piping. In freezing temperatures, ductile iron pipes are highly resistant to cracking or breaking. This is because of their unique metallurgical composition and structure. They possess a high tensile strength and can endure the expansion and contraction resulting from freezing and thawing cycles. Additionally, their smooth internal surface prevents ice or sediment buildup, ensuring efficient flow and reducing the risk of blockages. Overall, ductile iron pipes are a dependable and appropriate option for use in cold climates.

- Q: Does centrifugal cast iron pipe work well with lining cement? Will it scale and breed bacteria?

- Poor hydraulic performance and high energy consumption. The roughness coefficient of the prestressed reinforced concrete pipe is between 0.013 - 0.014, so that the pipeline resistance of the pipeline with the same pipe diameter is higher than that of the same water content. Because of its high roughness, after a period of use, the pipeline will be blocked by bacteria, shellfish breeding and reproduction. As the service life increases, the inner diameter of the pipe will gradually shrink and the resistance will increase.

- Q: What is the composition of ductile iron pipes?

- Ductile iron pipes are primarily composed of iron, with small amounts of carbon, silicon, manganese, and trace elements such as sulfur and phosphorus.

- Q: Can ductile iron pipe be used for high-pressure gas systems?

- Yes, ductile iron pipe can be used for high-pressure gas systems. Ductile iron pipe is known for its high strength and durability, making it suitable for applications that require high-pressure systems. It possesses excellent mechanical properties, including high tensile strength, yield strength, and impact resistance, which allow it to withstand the pressures associated with gas transmission. Furthermore, ductile iron pipe is resistant to corrosion, making it a reliable choice for long-term use in high-pressure gas systems. However, it is important to consider the specific requirements and regulations of the gas system, as well as consult with industry professionals, to ensure that the ductile iron pipe is installed and maintained correctly for optimal safety and performance.

- Q: What are the typical pressure surge protection measures for ductile iron pipe?

- There are several typical pressure surge protection measures for ductile iron pipe that help ensure its integrity and longevity. These measures include: 1. Surge tanks: Surge tanks are commonly used to absorb pressure surges and minimize their impact on the ductile iron pipe. These tanks are typically installed at critical points in the pipeline system, such as at pump stations or near valves, to provide a reservoir for excess pressure. 2. Air release valves: Air release valves are essential components in ductile iron pipe systems that help release trapped air and prevent the formation of air pockets. These valves help maintain a stable pressure within the pipe and reduce the risk of pressure surges during operation or sudden changes in flow. 3. Pressure relief valves: Pressure relief valves are designed to protect ductile iron pipes by releasing excess pressure when it exceeds a predetermined threshold. These valves are typically installed at strategic locations in the pipeline system and are set to open when the pressure exceeds a safe limit, diverting the excess pressure to prevent damage to the pipe. 4. Surge suppressors: Surge suppressors are devices that are installed in ductile iron pipe systems to absorb and dissipate pressure surges. These devices act as shock absorbers, reducing the impact of pressure fluctuations and preventing damage to the pipe. Surge suppressors are particularly effective in situations where pressure surges are frequent or severe. 5. Pipe wall thickness: Another crucial measure for pressure surge protection in ductile iron pipe is ensuring an appropriate pipe wall thickness. By selecting a pipe with the correct wall thickness, engineers can ensure that the pipe can withstand the pressure surges it may encounter during operation. This helps prevent pipe failure or rupture due to excessive pressure. It is important to note that the specific pressure surge protection measures implemented for ductile iron pipe may vary depending on the specific application, pipe size, operating conditions, and regulatory requirements. Consulting with experts in pipeline engineering and design is crucial to determine the most suitable pressure surge protection measures for a particular ductile iron pipe system.

- Q: How do ductile iron pipes perform in high-altitude areas?

- Ductile iron pipes perform well in high-altitude areas as they are highly resistant to corrosion and can withstand extreme temperature variations. The material's flexibility and strength make it suitable for handling increased pressure caused by altitude changes, ensuring reliable water distribution systems even in mountainous regions.

- Q: What are the risks in the process of conveying ductile iron pipes?

- Lifting: be careful lifting pipe, don't let the pipe shaking, lifting pipe by wire rope, sling and special sling, wire rope no single, for the protection of pipe coating, rubber or similar materials can be used to wrap up the rope. The use of hook, for the protection of the cement lining layer is not damaged, will hook with rubber or similar material wrapped up, especially in the hoisting of large diameter pipe, will not be fixed in the socket with hook in end strip or pipes.

- Q: Are ductile iron pipes suitable for wastewater pumping stations?

- Yes, ductile iron pipes are suitable for wastewater pumping stations. Ductile iron has high tensile strength, durability, and corrosion resistance, making it ideal for handling the abrasive and corrosive nature of wastewater. Additionally, ductile iron pipes have excellent pressure-bearing capabilities, ensuring reliable and efficient operation in wastewater pumping stations.

- Q: What material is ductile cast iron 235A?

- Nodular cast iron by spheroidization and inoculation by spherical graphite, effectively improve the mechanical properties of cast iron, especially the plasticity and toughness increased, resulting in higher than carbon steel. The strength of nodular cast iron is a kind of high strength cast iron material developed in 50s twentieth Century, its comprehensive performance is close to the steel. It is based on its excellent performance, has been successfully used in casting complex stress, strength, toughness and wear resistance requirements of the higher parts. Ductile iron has been the rapid development of cast iron material for application of gray cast iron, only very widely. The so-called "iron steel", mainly refers to the ductile iron.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 16

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords