Drywall System Stud Metal Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

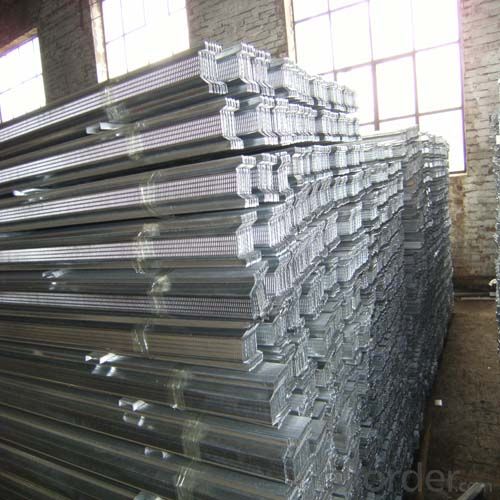

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

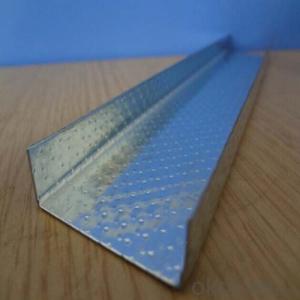

1. Raw material of partition light steel keel is high-quality hot dipped zinc galvanized steel strip, which is absolute damp proof , heat-insulating, highly durable , and highly rust resisting.

2. Hot dipped zinc galvanized steel strip zinc coating is 80-160g/m2.

3.Warm sales in Southeast Asia,Middle East , Africa , Oceania , Eastern Europe ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can guarantee accurate size, high-quality products.

Products data:

Component name | Descrption(mm) | Thickness(mm) | Length(mm) | Remark |

Main Channel | 38*10 | 0.45,0.50,0.60,0.70,0 .80,1.0 | 3000 | We can manufacture products on customers' specific requirement. |

38*12 | 0.50,0.6,0.7,0.8,1.0 | 3000 | ||

Furring Channel | 35*22 | 0.40,0.50,0.60 | 3000 | |

35*24 | 0.40,0.45,0.50,0.60 | 3000 | ||

Card Light Steel Keel | 19*25 | 0.6 | 3000 | |

19*28 | 0.8 | 3000 | ||

19*32 | 0.9 | 3000 | ||

19*38 | 1.0 | 3000 | ||

Stud | 40*34.5 50*34.5 70*34.5 75*34.5 100*35*32 | 0.40, 0.45, 0.50, 0.60, 0.70, 0.80 | 3000, 3200 | |

Track | 42*25 52*25 72*25 75*25 100*25 | 0.40, 0.45, 0.50, 0.60, 0.70, 0.80 | 3000, 3200 |

Product Overviews

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Lightweight wallboard light steel keel how to construction

- Damp room and steel plate plaster wall, light partition board keel spacing should not be greater than hundreds of millimeters, the installation of supporting keel, the support card should be installed in the direction of the vertical keel opening, partition wall card should be four hundred To six hundred millimeters, from the keel at both ends of the distance should be twenty to twenty five millimeters, should be fixed according to the location of the ball along the edge, along the keel and border keel, keel line should be coincident with the line.

- Q: The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- How to get someone else, please eat a meal, or simply do not thousands of dollars that deposit

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Load on the best no problem with red brick, that wall how many square meters, if the area is less than 10 square meters can be brick 120 red brick wall

- Q: Light steel keel with what screws fixed gypsum board

- 2.5cm self-tapping screw! Do not matter where you can use nails. In foreign countries, taking into account the factors of the earthquake, heaven and earth keel and vertical keel can not be nailed.

- Q: Light steel keel partition wall construction process is what

- Fixed Border keel: Border keylone along the position of the ball, the edge of the keel should be coincident with the elastic line. The end of the keel should be fixed, fixed point spacing should not be greater than lm, fixed should be solid.

- Q: Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Too general, and the regional difference, the amount of engineering, high-level factors led to a large spread. General tooling: light steel keel material 25 + artificial 20, gypsum board material 12 + artificial 8, scraping putty latex paint three times material 18 + artificial 12, gypsum board and latex paint count double. With auxiliary materials estimated total price of 150 or so.

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- Can be directly connected, but not solid. How are they all know what they are.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition is a high toughness material, compared to the traditional partition, better shock resistance. In the simulation of super 8 earthquake experiment, the traditional block wall has long been decomposed collapse, but the light steel keel inorganic composite board wall is still solid and reliable, showing its seismic capacity far more than the traditional wall, which is light steel Keel inorganic composite board partition in Japan widely used reasons, security is the primary consideration of residential construction factors.

- Q: What is the difference between gypsum board partitions and lightweight partitions?

- Gypsum board partition and lightweight partition the most important difference there are three points: First, the difference between the structure. Gypsum board is a skeleton-like partition, that is, to rely on the backbone of light steel keel can stand up, and light partition entirely by their own plate to cut off; Second, the difference between materials, gypsum board itself is only gypsum and pulp Composite products, and lightweight partition is made of sheet metal, wood chips, cement foam, additives, perlite composite wall;

- Q: Light steel keel partitions and finished partitions

- Light steel: the frame and the outer panel should be in the construction site processing, but also brush at least 2 times the putty +2 paint. Finished partition: mainly in the factory processing, in the field just assembled only.

Send your message to us

Drywall System Stud Metal Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords