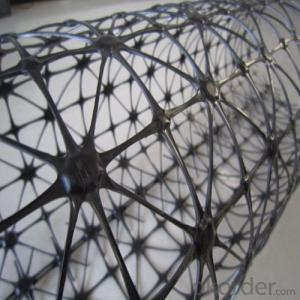

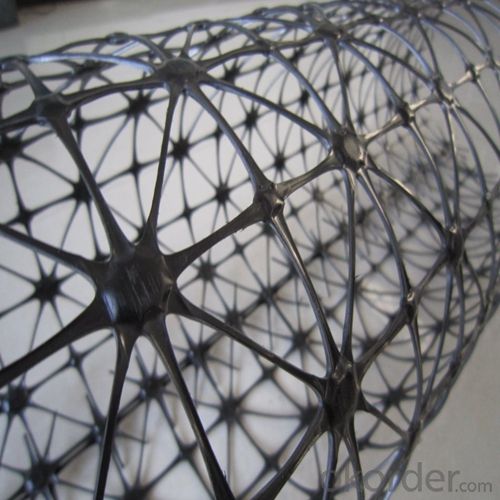

Drenaje Geotextil - Fiberglass Geogrid Polyethylene with Low Elongation and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Porducts Description

We offer a unique line of extruded polymer grids for protecting and reinforcing grassed vehicular areas. Reinforcement Mesh is a tough extruded polymer grid for reinforcing grassed areas used by vehicles and pedestrians. Grass Protection Mesh is a heavy-duty extruded polymer grid designed to protect and reinforce grassed areas subject to vehicle traffic. Track Mat is an extra heavy duty thermoplastic extruded mesh manufactured from high density polyethylene (HDPE) designed to support large weights.

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

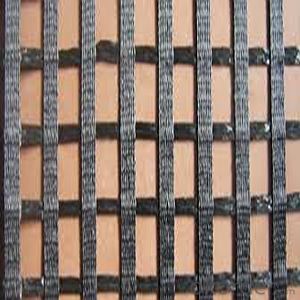

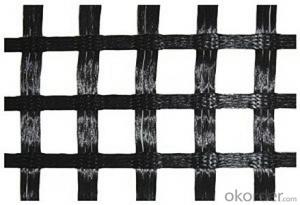

A: Yes, please check the pictures:

- Q: What are the specifications for geotextiles in subsurface drainage projects?

- The specifications for geotextiles in subsurface drainage projects typically include requirements for the material's strength, permeability, filtration properties, and durability. These specifications ensure that the geotextile can effectively separate soil particles from the drainage media, prevent clogging, and maintain its functionality over time. Additionally, the specifications may also address the geotextile's dimensions, weight, and installation guidelines to ensure proper performance in subsurface drainage applications.

- Q: Are geotextiles suitable for use in wetlands?

- Yes, geotextiles are suitable for use in wetlands. They are commonly used to stabilize soil and prevent erosion in wetland areas. Geotextiles provide effective filtration, drainage, and separation, while also allowing water and nutrients to flow through. Additionally, they are eco-friendly and do not harm the natural habitat of the wetlands.

- Q: Highway road crest u block below the geotextile roadway below the curb

- The use of steel template investment is too large, do not return the cost of the use of plastic template, the summer comes, will be the deformation of the current use of a curb stone molding machinery, prefabricated ratio can guarantee the strength of the mold release time, Segregation of water content, the mortar will stick mold, in short, the appearance of substandard match ratio can guarantee the strength, and this is only one aspect, you now encounter is the operability of concrete problems, but also in the mix of experimental templates The problem of stiffness is to ensure that the key to forming the surface of the finish problem is one of the factors, there is the effect of concrete vibrating and quality, concrete demolition of the time and so on. Addition agent, the rational use of release agent can be considered an auxiliary means

- Q: Geotextile price, the number of square feet per square

- You have different specifications and different prices. The number of square feet per ton to see how much you do grams, the greater the weight, the less the square number. Huazhi geotextile material manufacturers to answer.

- Q: How do geotextiles improve the performance of asphalt overlays?

- Geotextiles improve the performance of asphalt overlays by providing reinforcement and separation between the existing pavement and the new asphalt layer. These fabrics help distribute the load and prevent the mixing of materials, reducing cracking and increasing the overall durability and lifespan of the overlay.

- Q: Where is the geotextile in the municipal works?

- Conservation, consideration, there is more green and more Chinese geotextile material manufacturers

- Q: Filter geotextile, permeable geotextile, seepage geotextile What is the difference?

- The above three products are a product. But is divided into polypropylene staple acupuncture geotextile, polyester staple acupuncture geotextile, filament geotextile. Three categories. Play a major role is good permeability, filtration, isolation performance, construction convenience.

- Q: Geotextile universal testing machine with 20kn enough?

- Conventional geotextile mechanics test using 20KN test machine on it, individual users need to do some large range of mechanical tests, our company also has some customers choose 50KN universal testing machine. The specific choice of 20KN or 50KN to see if you are on the equipment requirements upwards compatible.

- Q: How do geotextiles help in preventing lateral spreading of soil?

- Geotextiles help in preventing lateral spreading of soil by providing a barrier that restricts the movement of soil particles, thereby reducing the potential for erosion and instability. The geotextile material acts as a separator, preventing the mixing of different soil layers and maintaining their integrity. It also enhances soil reinforcement, distributing the applied load more evenly and increasing the overall stability of the soil structure. Additionally, geotextiles improve drainage by allowing water to flow freely while preventing the loss of fine particles. Overall, geotextiles play a crucial role in preventing lateral spreading of soil and ensuring the long-term stability of various civil engineering projects.

- Q: What are the different types of geotextiles?

- There are several types of geotextiles, including woven geotextiles, non-woven geotextiles, and knitted geotextiles. Each type has its own unique properties and characteristics that make them suitable for various applications in civil engineering, construction, and environmental projects.

Send your message to us

Drenaje Geotextil - Fiberglass Geogrid Polyethylene with Low Elongation and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords