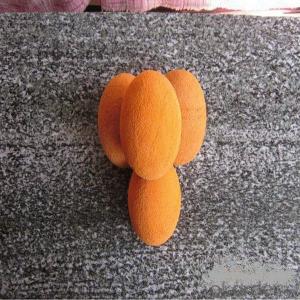

DN80 soft rubber cleaning ball for wear concrete pump pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DN80 soft rubber cleaning ball for wear concrete pump pipe

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: What solvent is used to clear the melted rubber layer?

- The acetone extractives are some fatty acids and steroids, some natural antioxidants and accelerators, and can help with the powdery agent in the process of mixing and dispersion of rubber softening effect.Ash containing mainly magnesium phosphate and calcium phosphate salts, copper, manganese, iron and other metal compounds is very small, because these valence metal ion can promote the aging of rubber, so their content should be controlled.

- Q: Are rubber products poisonous? What harm?

- A product of a combination of many components, produced by certain cross reactions, with high elasticity. In general by the rubber, filler, plasticizer, active agent, accelerator, curing agent and other additives (pigment, odor, conductive composition etc.).

- Q: How long is the warranty period for EPDM?

- (1). Rubber molding, after pressing, the elastic body is within the cohesion can not be eliminated, the molding die, often have a very unstable contraction (rubber shrinkage due to rubber vary), required after a period of time, and can be stable. Therefore, when a rubber product design at the beginning, regardless of formula or mold, it is necessary to carefully calculate the coordination, if not, it is easy to produce product size instability, resulting in lower quality products.(2). A rubber elastic body of thermosetting plastic hot melt, belongs to the hot cold setting. Rubber due to different types of sulfide species, its molding and curing temperature range is also a considerable gap, and even can be affected by climate change, indoor temperature and humidity affected. Therefore, the production conditions of rubber products need to be adjusted at any time. If not, the quality of the products may be different.(3) rubber products are made of rubber raw materials and used as raw materials made from the rubber compound of the mixer, and the formula is designed according to the characteristics of the required rubber products, and the required hardness of the products is determined. The product is made and molded by rubber flat vulcanizing machine. Finally, the product is processed by flying edge, and the surface of the product is treated smoothly without burrs.(4). Aging test of rubber products aging test belongs to the category of rubber aging refers to rubber and products in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors caused by the performance of the structure change, then the loss of use value phenomenon. They are crazing, sticking, hardening, softening, powdering, discoloration, mildew, etc..

- Q: Excuse me, is PU one kind of silicone? Or what is the connection between the two?

- PU is the abbreviation of Polyurethane, Chinese name is polyurethane, referred to as polyurethane. Because of the simple modification of the formula, different density, elasticity, rigidity and other physical properties can be obtained. At present, a large number of glass fiber insulation materials, wood, traditional rubber products and so on.

- Q: For the application of common synthetic rubber, not too long or too difficult, want to do

- Polybutadiene rubber (BR) is formed by polymerization of butadiene rubber CIS structure. The advantages are: flexibility and excellent abrasion resistance, good aging resistance, low temperature resistance is excellent in heat under dynamic load is small, easy to metal bonding. The disadvantage is low strength, tear resistance, processability and self-adhesive poor. Using temperature range: - 60 DEG C ~ + 100 DEG C. The general and natural rubber or butadiene rubber and tire tread, main production and transportation with cold and special products.

- Q: How to identify the tire rubber is raw or cooked

- Rubber is a kind of polymer material with high elasticity, is the parent material manufacturing of rubber products, generally refers to the rubber unvulcanized. A nearly neutral liquid produced by a rubber tree and added with 0.05%~0.1% ammonia water to make latex (for a short period of time). Most of the latex need processed dry glue, all kinds of natural rubber is often said.

- Q: Is polyurethane and polyurethane rubber one thing?

- The biggest difference between the plastic and the rubber is the performance of the plastic properties of high tensile strength, but low toughness, toughness and rubber are relatively high, mainly related to the glass transition temperature of material, high glass transition temperature of plastics, because of its high hardness, low toughness.

- Q: What is food grade natural rubber?

- Natural rubber obtained from natural rubber juice in a rubber tree and processed according to food safety requirements. It is used to process rubber products in contact with food products.

- Q: What is the rubber composition and function of the airplane tyres?

- Polybutadiene rubber is prepared by the solution polymerization of butadiene butadiene rubber, with excellent cold resistance, abrasion resistance and flexibility, but also has good anti-aging properties. Polybutadiene rubber is mostly used in the production of tires, a small part for manufacturing cold products, cushioning materials and belt and rubber shoes. Butadiene rubber drawback is the tear resistance of the cross, wet skid resistance is not good. Isoprene rubber is the abbreviation of polyisoprene rubber. It is produced by solution polymerization. Isoprene rubber, like natural rubber, has good elasticity and wear resistance, excellent heat resistance and good chemical stability. Isoprene rubber (not before processing) strength was significantly lower than that of natural rubber, but the quality uniformity, processing performance is better than natural rubber. Isoprene rubber can be used instead of natural rubber to make heavy-duty and off-road tires, and can also be used to produce all kinds of rubber products.

- Q: What are the disadvantages of a rubber roof?

- Housing rubber roof area must be greater than the housing area, mainly for water and rubber, heat up, cold weather.

Send your message to us

DN80 soft rubber cleaning ball for wear concrete pump pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords