Low Pressure Continuous Sandwich Panel Production Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

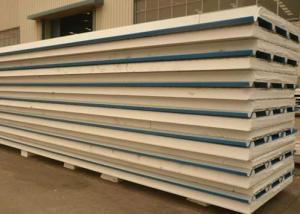

General Information of Low Pressure Continuous PU Sandwich Panel Production Line

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

Sandwich panel, as a new building material shows excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Specifications of Low Pressure Continuous PU Sandwich Panel Production Line

Reuqire specifications of raw materials:

Thickness of panel: 0.37-1.2mm

Track width (max): 1250mm

Weight of uncoil (max): 5 tons

Inner dia: 500-600mm

Dimension of the sandwich panel available to produce

Length: 2-20m

Width: 900-1100mm

Panel thickness (min): 30mm

Panel thickness (max): 200mm

Production/Operation rate: 3-10m/min

Length of the whole production line: about 120m

Useful length of the double track: 25m

Working height: 1200mm

The pressure of pour foaming: 150-200 bar

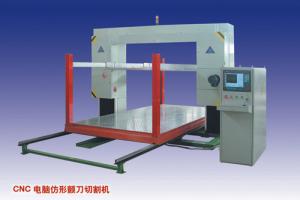

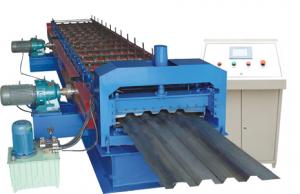

Complete line consist of:Uncoiler (auto), Forming machine, Steel/Panel heating machine, Heating frame (move auto), Foaming machine, Main engine with double track, Heating machine with double track, Band saw cutter, Automatic stacker and Auto electric controller

Applications of Low Pressure Continuous PU Sandwich Panel Production Line

This metal forming machine is indispensable equipment for producing the wall panel and roof panel for industrial workshops, warehouses etc.

Technical Data of Low Pressure Continuous PU Sandwich Panel Production Line

1. The Manufacture Speed Of Sandwich Panel:4m/min

2. The Thickness Of Sandwich panel:30-200mm

3. The Thickness Of Steel : 0.4-0.8mm

4. The Length Of the Production Line : about 80meters

5. The Total Power Of The Production Line : 200KW

6. The Length Of The Double Belt Conveyer : 8m

Packaging & Delivery of Low Pressure Continuous PU Sandwich Panel Production Line

1. Main machine is covered by plastic film.

2. PLC computer control box, spare parts and other small parts are packed by wooden carton box.

3. Delivery: 80 days.

- Q: How can the wire laying in the foam sandwich panel workshop meet the fire protection requirements?

- Outside the wire is a pipe, that is, through the pipe laying, if the pipe is galvanized steel pipe, and buried in the wall, floor, floor and so on inside can not see, it is called galvanized steel pipe concealed.

- Q: How to thread the EPS (color steel) sandwich panel?

- Of course, PVC flame retardant tubes, ha ha, I suggest that our company is to do foam sandwich board, the general customers are doing so.

- Q: Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- Now there is the middle lane is a honeycomb galvanized plate board online, I know this is the direction of future development is the absolute fire, there is air, that summer is not too hot, winter is not too cold.

- Q: Polyurethane sandwich panel production line?

- Polyurethane sandwich panel production line, namely polyurethane composite insulation board production line, is made up of two layers: cement, aluminum foil and non-woven,In the soft base material such as cloth and paper, special equipment for producing phenolic resin (polyurethane) foam sandwich board, the thickness of sandwich panel is 20-100mm, width 1200mm, length is fixed.

- Q: What's the difference between sandwich board and composite board?

- The metal sandwich panel is made of two layers of metal panels (or other material panels), which are made of heat preservation material and are compounded by adhesive compound or direct foaming.

- Q: Rock wool, color steel sandwich plate production line where good?

- Company's R & D and production of rock wool polyurethane sandwich board equipment, rock wool, /EPS color steel sandwich board equipment, can produce all kinds of different types of fire insulation board.

- Q: What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- Foam sandwich board, beautiful shape, bright color, good overall effect, it sets the bearing, thermal insulation, waterproof in one, and no two decoration, is a widely used, especially in the temporary facilities for construction sites such as office, warehouse, wall and so on, but also the modern construction site civilization construction.

- Q: What does color steel sandwich board mean?

- The finished products of the sandwich panel are easy to install, light and efficient. The filling system also uses the closed bubble molecule structure to prevent the condensation of water vapor.

- Q: How to install the pre embedded pipe in the clean room sandwich panel?

- Engineering sandwich plate decoration, wall structure in construction completed, outside the installation of doors and windows, clean air conditioning indoor ceiling above the air supply pipe, various pipes, cable and wiring pipe, pipe insulation after the completion of a special decoration engineering.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Eastern Europe North America Southeast Asia Africa South America North America |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 8-10people |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | 10,000square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Low Pressure Continuous Sandwich Panel Production Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords