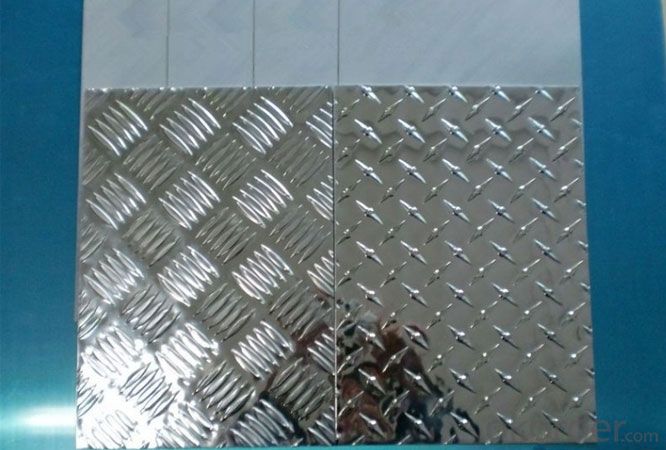

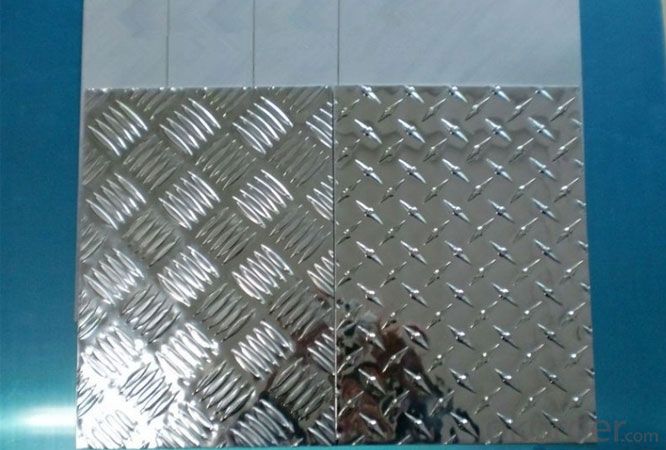

Diamond Tread Plate Decorative Embossed Aluminum Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Shipping

Packing : Export wooden pallets. The bundle wegiht not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 20MT

About us

CNBM is a modern and diversified enterprise specialized in manufacturing and sales of aluminum coil/sheet/stripe/foil products. The manufacturer is located in Henan province covering an area of 80000 square meters, existing staff more than 800 people, many sales offices around the world.

It is CNBM “making all efforts on hard working and always seeking innovations”. Maximize your satisfactory is our service goal. With the management idea of “service specialization, product seriation”, All CNBM people are striving for CNBM’s bigger and stronger prospects. We aim to build up CNBM as the first-class aluminum processing enterprise in the world.

OUR CERTIFICATES: ISO9001, SGS, BV, CIQS

Professional, over 20 years aluminum producing experience

Reliable, over 25 years export experience

Qulified, SGS, Bureau Veritas, ISO9001, CIQS certificates

We are now supply to Italy, USA, MEXICO, YEMEN, SYRIA and Brazil market , could be used for the electricity industry, powerstation Industry, decoration and other industry usage.

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union,etc.

Welcome to vist our factory to test the quality, service and reputation

- Q: What is the lifespan of aluminum sheets?

- Various factors, such as the aluminum's grade and thickness, the environmental conditions it encounters, and the level of maintenance it receives, can impact the lifespan of aluminum sheets. Aluminum sheets are renowned for their durability and resistance to corrosion, which contributes to their long lifespan. Aluminum possesses natural resistance against rust and corrosion, making it suitable for a wide array of applications. When given proper care and maintenance, aluminum sheets can endure for numerous years. The construction, automotive, and aerospace industries frequently utilize aluminum sheets due to their lightweight nature and robust properties. In outdoor settings, aluminum sheets can withstand harsh weather conditions, including extreme temperatures, humidity, and exposure to UV radiation. Nevertheless, continuous exposure to certain chemicals or corrosive substances can gradually cause damage. To prolong the lifespan of aluminum sheets, it is crucial to regularly clean and safeguard them. This entails eliminating any dirt or debris that might accumulate on the surface and applying protective coatings or treatments as necessary. In conclusion, while it is challenging to provide an exact timeframe for the lifespan of aluminum sheets, they are generally regarded as a long-lasting material that can withstand the test of time when adequately maintained.

- Q: What are the different thicknesses available for aluminum sheet?

- Aluminum sheets come in various thicknesses, spanning from very thin to thick. The thickness of these sheets is measured either in gauge or millimeters (mm), with each gauge denoting a specific thickness. The prevalent gauges for aluminum sheets are 22, 24, 26, 28, 30, and 32, corresponding to thicknesses ranging from 0.0254 mm to 0.635 mm. Moreover, thicker gauges, such as 16 gauge (1.29 mm) or even more substantial ones, can be found for specialized applications. The preferred thickness of an aluminum sheet is determined by its intended use. Thinner sheets are often utilized for lightweight purposes, including electronics or packaging, while thicker sheets are more suitable for structural or industrial needs.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- If they are the correct size for your Blazer, I'd go with the aluminum rims, especially at only $100 bucks. They are lighter, which will help with handling and will definitely be better looking. I would not be too concerned with potholes or damaging them from curbs as with an SUV you will most probably have a higher profile tire (probably a 65-70 series sidewall) which puts more rubber between your rim and the road. One more thing, aluminum rims CAN crack and damage easily, so before handing over your cash, I'd check the outside surfaces as well as the INSIDE surfaces for any damage.

- Q: Can the aluminum sheets be used for manufacturing architectural sunshades?

- Aluminum sheets are indeed suitable for the production of architectural sunshades. This material is commonly chosen for sunshades because of its lightweight quality, durability, and resistance to corrosion. It can be effortlessly shaped and sized, providing versatility in design. Moreover, aluminum possesses exceptional heat reflectivity attributes, effectively minimizing solar heat absorption and offering shade to buildings. In conclusion, aluminum sheets serve as an excellent choice for the manufacturing of architectural sunshades.

- Q: Can aluminum sheet be welded?

- Yes, aluminum sheet can be welded. Aluminum is a versatile metal that can be easily welded using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). However, welding aluminum requires special considerations due to its high thermal conductivity and low melting point compared to other metals. It is important to choose the appropriate welding process, filler material, and shielding gas to ensure a successful weld. Additionally, proper surface preparation, including cleaning and removing any oxide layer, is crucial for achieving a strong and durable weld in aluminum sheet.

- Q: 1. Why does aluminium resist corrosion?2. How do we make aluminium stronger?3. Why does titanium resist corrosion?4. What properties make titanium ideal to use in jet engines and nuclear reactors?5. Why do we need electricity to make aluminium and titanium?6. Why does recycling aluminium save electricity?Even if you only know the answer to one question the help will be much appreciated :D

- 1. When exposed to air, pure aluminium rapidly forms a passive oxide layer, alumina, which further inhibits aluminium reactions with other elements. 2. Aluminium can be made stronger by alloying with other elements. One of the most known aluminum alloy is duraluminium, where the principal alloying component is copper. 3. Exactly as aluminium, titanium corrosion resistance is due to its high reactivity with oxygen. When pure titanium is exposed to air it forms a passive titanium dioxide layer on the surfaces exposed which further prohibits other reactions with corrosion agents. 4. The use of titanium in jet engines components is favored by its strength to weight ration, which is unmatched by any other metal. As for the nuclear reactors, its use is preferred because of its superior corrosion resistance associated with fracture toughness and overall durability. 5. Both titanium and aluminium are refined from their respective mined ores - bauxite, for aluminium, ilmenite and rutile for titanium. Basically, these are oxides of the metals. Pure metal has to be reduced from these ores and processes involve use of temperatures up to and sometime exceeding 1000 degrees Celsius, which obviously requires a great consumption of energy, including electricity. Moreover, pure aluminium is obtained in the final processing phase through electrolysis, meaning an electrical current is needed in order to drive the required chemical reactions, thus adding to the electrical consumption. 6. Recycling aluminium from aluminium simply requires the remelting of the metal, eliminating the electrolytic phase that is high electric energy consuming.

- Q: Need to polish some small aluminum tubing, preferably to chrome like shine. What tools do I need? Thinking about buying 6 bench grinder, buffing? wheels and polish compound... Does it sound about right?

- Aluminum oxidizes almost instantly, so it is never going to keep a good shine. You can send it to a plating shop and they will anodize it, which means a permanent oxidized layer and that may or may not retain some shine but at least it won't ever change much. (But it is easily stained.) Consider plating some other metal on the surface. You will need advice from a plating shop about that. Maybe you could use chrome plated water pipe? That would be cheaper than a custom job.

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can definitely be used in the construction industry. Aluminum is a versatile and lightweight material that offers several advantages for construction applications. It is corrosion-resistant, which makes it ideal for outdoor structures and buildings. Aluminum sheets are commonly used for roofing, siding, window frames, doors, and other architectural elements. Additionally, aluminum's high strength-to-weight ratio allows for the construction of durable and efficient structures. Its malleability also makes it easy to fabricate and shape into various forms, allowing for creative and innovative designs in construction projects. Overall, aluminum sheets are a popular choice in the construction industry due to their durability, versatility, and aesthetic appeal.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a highly conductive material, making it suitable for use in grounding systems. It is often used in various electrical applications due to its low resistance and excellent electrical conductivity. Aluminum sheet can effectively carry electrical current and safely dissipate it into the ground, ensuring the protection of electrical systems and preventing electrical hazards. Additionally, aluminum's lightweight and corrosion-resistant properties make it a preferred choice for grounding applications in various industries, including construction, automotive, and aerospace.

Send your message to us

Diamond Tread Plate Decorative Embossed Aluminum Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords