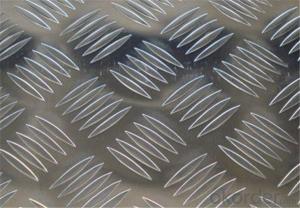

DC/CC stucco embossed aluminum sheet 1050/1060/1100/3003/3104/5052/5083

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolling aluminum sheets &coils:

ALLOY | SEPCIFICATION | TEMPER | |

THICKNESS | WIDTH | ||

1100,1200,1145,1235,1050,1060,1070 | 0.200-6.0 | 900-190025-1900 | O,H22,H14,H24,H16,H26,H18 |

3003,3A21,3103,3105,3402 | 0.200-6.0 | 900-190025-1900 | O,H14,H24,H16,H26,H18 |

5052,5A02,5005,5754,5083 | 0.200-6.0 | 900-190025-1900 | O,H14,H24,H16,H26,H18,H36,H38 |

Embossed aluminum sheets

ALLOY | SEPCIFICATION | TEMPER | |

THICKNESS | WIDTH | ||

1100, 1050,1060,1070 | 1.0-5.0 | 1000-2200 | H114,H112 |

3003,3004,3105 | 1.0-5.0 | 1000-2200 | H114,H112 |

5052,5005,5754,5083 | 1.0-5.0 | 1000-2200 | H114,H112 |

Roller coating sheet &coils

ALLOY | SEPCIFICATION | TEMPER | |

THICKNESS | WIDTH | ||

AA1100, AA1050,AA1060 | 0.3-2.5 | 20-1850 |

All tempers |

AA3003,AA3004,AA3105 AA3005,AA3104 | 0.3-2.5 | 20-1850 | |

AA5052,5005,5754,5083 | 0.3-2.5 | 20-1850 | |

Company Information

CNBM have a registered capital of US$ 300 million. Our company is engaged in the production and trade of all kinds of aluminum steel finished and unfinished products.aluminum sheet is our main production and sell well. We have established business relationships with clients in the Korea, Japan, Singapore, Iran, Dubai, Yemen, Chile, Brazil, France, UK, Italy, Canada and more than 20 countries and regions for aluminum sheet Annual sales revenue is USD 50 billion. The details of payment method, delivery time and minimium quantity and so on for aluminum sheet can be negotiated according to the order.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Aluminum sheets are indeed appropriate for utilization in the food processing and packaging sectors. The food industry extensively employs aluminum due to its exceptional properties and advantages. To begin with, aluminum is a safe material for direct contact with food as it is non-toxic. It does not react with food or affect its taste, guaranteeing the preservation of the original flavor and quality. This is particularly crucial in packaging, as it aids in maintaining the freshness and integrity of the food product. Moreover, aluminum possesses excellent thermal conductivity, enabling efficient and uniform heat distribution during food processing. This attribute is advantageous in cooking, baking, and other thermal procedures, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets exhibit outstanding barrier properties, including resistance to moisture, light, and gases. This shields food from external factors that could potentially degrade its quality, such as moisture or oxygen. It also extends the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet sturdy and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and safeguards the food during transportation and storage. Lastly, aluminum is an environmentally sustainable material. It is fully recyclable, meaning it can be reused without losing its properties. This aids in reducing the environmental impact and supports the concept of a circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: What are the standard sizes of aluminum sheets?

- The standard sizes of aluminum sheets vary, but some common dimensions include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet.

- Q: Can aluminum sheets be bent without breaking?

- Aluminum sheets possess the remarkable ability to endure bending without shattering. As a metal, aluminum boasts exceptional malleability and ductility, rendering it effortlessly moldable and pliable. This quality renders aluminum an optimal substance for a wide array of purposes, encompassing the production of aircraft, automobiles, and household articles. The pliability of aluminum sheets facilitates the crafting of intricate designs and intricate forms, establishing it as an exceptionally adaptable substance. It is, nonetheless, worth mentioning that the thickness and caliber of the aluminum sheet may impact its susceptibility to bending. Thicker sheets may necessitate increased force and specialized tools to achieve the desired curvature, whereas softer aluminum grades may yield to bending with greater ease.

- Q: What is the atomic mass of aluminum?

- Aluminum has an atomic mass of roughly 26.98 atomic mass units.

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- Bass Tracker Aluminum Boats

- Q: What are the different methods of surface cleaning for adhesive bonding of aluminum sheet?

- There are multiple techniques available for surface cleaning when it comes to adhesive bonding of aluminum sheet. These techniques comprise mechanical cleaning, chemical cleaning, and plasma cleaning. 1. In the case of mechanical cleaning, the objective is to physically eliminate any impurities or debris from the aluminum sheet's surface. This can be accomplished through various means such as sanding, grinding, or scrubbing with abrasive materials. Although mechanical cleaning effectively gets rid of loose particles and surface imperfections, it may not be able to eliminate all types of contaminants. 2. Chemical cleaning, on the other hand, involves the utilization of specific cleaning agents or solvents to eliminate impurities from the aluminum surface. These cleaning agents have the ability to dissolve or dislodge dirt, grease, oil, or other organic substances. To ensure thorough surface preparation, chemical cleaning is often combined with mechanical cleaning. It is crucial to select a cleaning agent that is compatible with both the adhesive and the aluminum sheet to avoid any adverse reactions. 3. Plasma cleaning, a more advanced technique, employs ionized gases to clean and activate the surface of the aluminum sheet. The plasma generates reactive species that can break down and eliminate contaminants, while also creating active sites for improved adhesion. Plasma cleaning is highly effective in removing organic and inorganic impurities, as well as oxide layers that might impede bonding. Each method possesses its own strengths and limitations, and the choice of surface cleaning technique relies on the specific requirements of the adhesive bonding process. Thorough evaluation of the surface condition and identification of the type of contaminants present are crucial in determining the most suitable cleaning method. Additionally, proper adherence to surface preparation techniques is vital to ensure successful adhesive bonding of aluminum sheet.

- Q: The user is asking if it's possible to substitute recycled aluminum sheets for new ones in a project or application.

- <p>Yes, you can use recycled aluminum sheets instead of new ones in many applications. Recycled aluminum maintains the same properties as new aluminum, making it suitable for construction, manufacturing, and various other uses. It's also more sustainable and cost-effective. However, it's important to ensure that the recycled aluminum meets the required specifications and quality standards for your specific project to avoid any structural or performance issues.</p>

- Q: Is it possible to purchase recycled aluminum sheets from a local supplier or manufacturer?

- <p>Yes, you can buy recycled aluminum sheets from local suppliers or manufacturers. Many businesses specialize in recycling and repurposing materials, including aluminum. To find a local supplier, you can search online directories or use business listing services. Additionally, contacting local recycling centers or metalworking businesses may provide leads on available recycled aluminum sheets. It's important to consider the quality, certifications, and environmental impact of the recycled materials when making your purchase.</p>

- Q: This question asks about the various types of aluminum foil used specifically for the purpose of food packaging.

- <p>Aluminum foil used for food packaging comes in several types, each with specific applications: 1. Heavy-duty foil: Strong and durable, used for roasting meats and baking. 2. Light-duty foil: Thinner and more flexible, ideal for lining baking sheets and wrapping foods. 3. Reynolds Wrap: A brand known for its non-stick and heavy-duty aluminum foils, suitable for a wide range of cooking and baking needs. 4. Aluminum foil rolls: Available in various widths, used for general food wrapping and sealing. 5. Pre-cut aluminum foil squares: Convenient for individual food portions and small wrapping tasks. Each type offers different levels of heat resistance, malleability, and non-stick properties, catering to diverse food packaging requirements.</p>

- Q: What is the fatigue strength of aluminum sheets?

- The fatigue strength of aluminum sheets varies depending on several factors such as the alloy composition, thickness, surface condition, and the specific loading conditions. Aluminum alloys generally exhibit good fatigue strength, particularly when compared to other metals. The fatigue strength of aluminum sheets is typically determined through fatigue testing, where specimens are subjected to cyclic loading until failure. The S-N curve, which represents the relationship between the number of cycles to failure (N) and the applied stress amplitude (S), is used to characterize the fatigue behavior of aluminum sheets. Aluminum alloys, such as 2024-T3 and 6061-T6, commonly used in aerospace and automotive industries, have high fatigue strengths and can withstand millions of cycles at certain stress levels. For example, 2024-T3 aluminum alloy has a fatigue strength of approximately 105 MPa (15,000 psi) at 10^6 cycles, whereas 6061-T6 aluminum alloy has a fatigue strength of around 96 MPa (14,000 psi) at the same number of cycles. It is important to note that the fatigue strength of aluminum sheets can be influenced by various factors, such as the presence of surface defects, corrosion, temperature, and loading frequency. Proper surface preparation, including smoothing and removing sharp edges, can increase the fatigue strength of aluminum sheets. Additionally, the use of proper stress relief treatments and design considerations, such as avoiding stress concentrations and optimizing joint design, can also improve the fatigue performance of aluminum sheets. Overall, the fatigue strength of aluminum sheets is generally considered to be good, but it is important to consider the specific alloy, thickness, surface condition, and loading conditions to accurately determine and optimize the fatigue performance in practical applications.

Send your message to us

DC/CC stucco embossed aluminum sheet 1050/1060/1100/3003/3104/5052/5083

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords