Aluminum Bronze Sheets for DC Aluminium Car Trailer Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of DC Aluminium sheet for making car trailer

CC Aluminium sheet for making trailer is one semi-finished aluminium material. This sheet can be cut to size you wanted in production. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of DC Aluminium sheet for making car trailer

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of DC Aluminium sheet for making car trailer

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of DC Aluminium sheet for making car trailer

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of DC Aluminium sheet for making car trailer

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

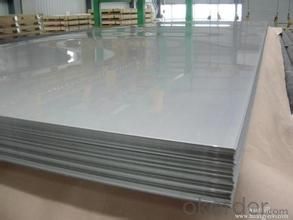

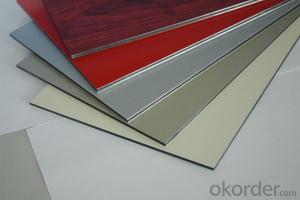

6. Image of DC Aluminium sheet for making car trailer

7. Package and shipping of DC Aluminium sheet for making car trailer

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the density of the 2A12 aluminum plate?

- 2.75 density. Shenzhen dexincheng metal plate is sold. Specifications are all complete.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Indeed, it is possible to bend or form aluminum sheets without causing cracks or breaks; however, this outcome is contingent upon the thickness of the sheet as well as the bending or forming technique employed. Aluminum, being an exceptionally pliable material, can be easily manipulated into various shapes without fracturing. Nevertheless, if the sheet is excessively thin or if the bending or forming procedure lacks carefulness and precision, there is a possibility of cracks or breaks occurring. To mitigate this risk, it is imperative to utilize appropriate tools and methods, such as a bending brake or a rolling machine, and to ensure that the sheet is not subjected to excessive force or stress during the process. Furthermore, annealing the aluminum sheet prior to bending or forming can enhance its flexibility and diminish the likelihood of cracking. Ultimately, with the correct approach and necessary precautions, it is feasible to successfully bend or form aluminum sheets without encountering cracks or breaks.

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The optical properties of aluminum sheet are significantly influenced by its surface finish. Optimal light reflection and minimal scattering are achieved with a smooth surface finish, leading to heightened reflectivity. Consequently, this amplifies the brightness and reflectiveness of the aluminum sheet. Conversely, a rough or textured surface finish on aluminum sheet provokes light scattering in various directions, thereby diminishing reflectivity. Consequently, this yields a lackluster and less reflective appearance. Furthermore, the surface finish has an impact on the visual aspect of any coatings or films applied to the aluminum sheet. A smooth surface finish promotes superior adhesion and uniformity of coatings, thus augmenting their optical properties. To conclude, the optical properties of aluminum sheet are improved with a smooth surface finish, as it enhances reflectivity and diminishes scattering, ultimately resulting in a more vibrant and reflective appearance.

- Q: Are aluminum sheets suitable for water storage applications?

- Yes, aluminum sheets are suitable for water storage applications. Aluminum is a corrosion-resistant material and does not rust, making it ideal for storing water without any negative impact on its quality. Additionally, aluminum sheets are lightweight, durable, and easily moldable, allowing for the construction of various water storage containers and tanks.

- Q: How do i prepare the aluminium sheet to paint with oils on it?Do I have to buy special aluminium or any kind will work?

- Any aluminium will do. Sandpaper it 3 times with decreasingly coarse grain papers, clean it thoroughly with turpentine and then apply 3 coats of white oil based paint. Gesso would do too, but you'd have to use more layers

- Q: Is it feasible to recycle aluminum sheets and what factors contribute to its recyclability?

- <p>Yes, aluminum sheets can be recycled easily. Aluminum is one of the most recycled materials due to its lightweight, durability, and the energy efficiency of the recycling process. The recycling of aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it an environmentally friendly choice. Proper sorting and collection systems are crucial for efficient recycling, and the demand for recycled aluminum is high in various industries, further facilitating its recycling process.</p>

- Q: What is the surface hardness of aluminum sheets?

- The surface hardness of aluminum sheets can vary depending on the alloy and treatment process. Generally, aluminum sheets have a relatively low surface hardness compared to other metals such as steel or titanium. However, certain aluminum alloys can be heat-treated to improve their hardness. For example, 6061-T6 aluminum sheets have a surface hardness of around 95 Brinell, while 7075-T6 aluminum sheets have a surface hardness of approximately 150 Brinell. It is important to note that these values are approximate and can vary depending on the specific alloy, temper, and processing conditions.

- Q: Are aluminum sheets suitable for food storage applications?

- Yes, aluminum sheets are suitable for food storage applications. Aluminum is a non-toxic and non-reactive metal that does not impart any taste or odor to food. It provides an excellent barrier against light, moisture, and oxygen, which helps in preserving the quality and freshness of the stored food. Additionally, aluminum sheets are lightweight, durable, and recyclable, making them a popular choice for food storage.

- Q: How do you calculate the price and weight of aluminum sheet?

- Aluminum prices this year. The best SWA seems to nearly 500 square meters.In more detail, you'll have to ask the supplier

- Q: Alumina is the protective coating that covers aluminum when exposed to oxygen. It's actually corroded aluminum that prevents the aluminum from continuously corroding.What I didn't know until recently was that alumina is an electrical insulator. If that's the case why then isn't aluminum an insulator if one is trying to pass current along its surface?

- Aluminum is an efficient conductor of electricity. A usual fabric that is not conductive is glass but glass will habits heat. Wood isn't warmth conductive or an electricity conductor however has a low combustion factor. You probably have a specific utility you are watching for then you definitely'd better ask extra certain questions.

Send your message to us

Aluminum Bronze Sheets for DC Aluminium Car Trailer Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords